High speed paperboard placing machine

A cardboard, high-speed technology, applied in the field of high-speed cardboard placement machines, can solve the problems of not meeting production requirements, slow placement speed, complex structure, etc., and achieve the effect of strong adaptability to products, fast placement speed, and stable grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

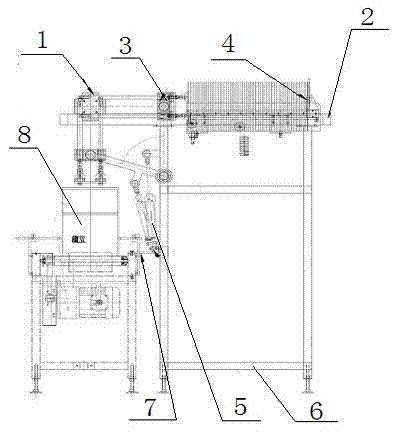

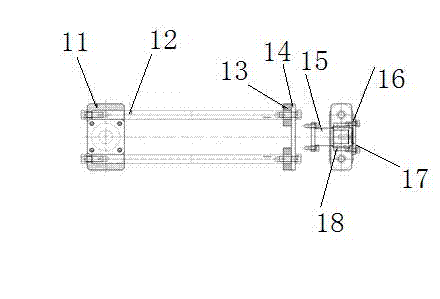

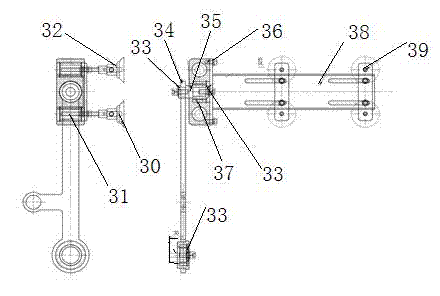

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the high-speed cardboard placement machine includes a rotating mechanism 1, a frame 2, a swing mechanism 3, a storage mechanism 4, a cylinder 5, a leg 6 and a connecting plate 7, a rotation mechanism 1, a swing mechanism 3 and a storage mechanism 4 Installed on the frame 2 respectively, the cylinder 5 is installed on the leg 6 through the hinge seat, the turning point of the pendulum mechanism 3 is assembled with the rotation mechanism 1 through a linear bearing, the connecting plate 7 is connected with the cylinder 5, and the rotation mechanism 1 includes a rotation seat 11 , linear bearing optical axis 12, polyurethane shock absorbing pad 13, end plate 14, fixed seat 15, stuffy cover 16, gland 17 and deep groove ball bearing 18, rotating seat 11 passes through deep groove ball bearing 18, gland 17 , stuffy cover 16, screws are connected with the mounting seat on the frame 2, the linear bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com