Movable filling template for tunnel bolt-shotcrete support concrete trolley and construction technology thereof

A construction technology and concrete technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of large springback and concrete waste, and achieve the effects of avoiding waste, short construction time and fast placement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed explanation through specific implementation mode below:

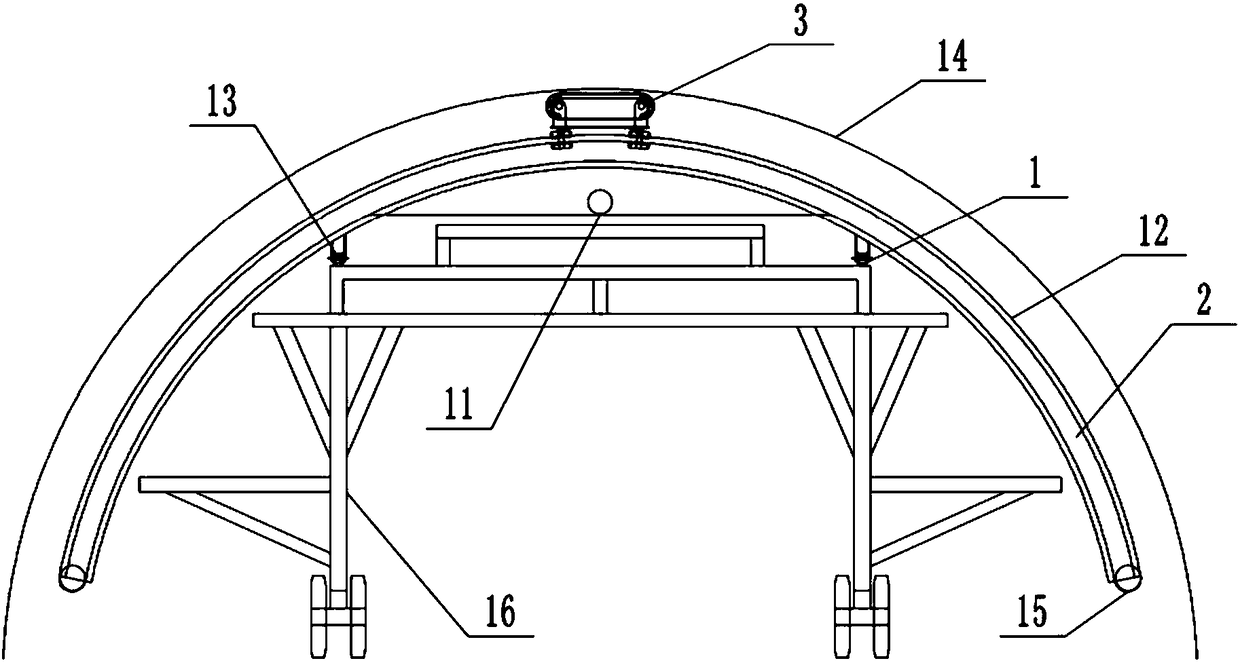

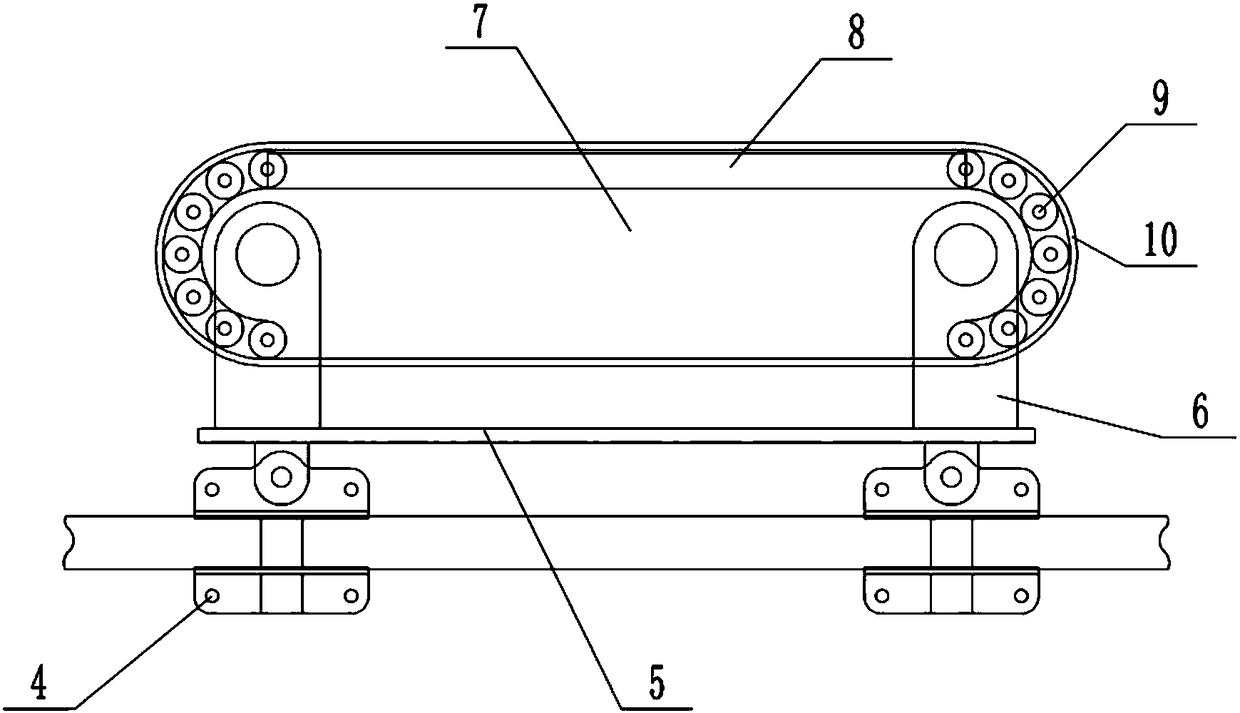

[0026] The reference signs in the accompanying drawings of the description include: translational track 1, arc track 2, sliding form trolley 3, pulley 4, support plate 5, support 6, sliding form trolley body 7, steel mold 8, roller 9, rolling form Roller 10, electric winch 11, ring transmission rope 12, walking wheel 13, arch frame 14, guide wheel 15, construction trolley 16.

[0027] Examples of the present invention figure 1 and figure 2 As shown, the mobile pouring formwork and construction technology for the concrete trolley for anchoring and shotcreting support of the tunnel, the specific steps are as follows:

[0028] Step 1: Treatment of the rock surface affected by spraying. Generally, high-pressure water is used to wash the floating dust and cuttings on the rock surface of the sprayed rock surface.

[0029] Step 2: Concrete mixing and transportation. Wet shotcrete mixing adopts fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com