Automatic loading mechanism for hole circlip for automobile front axle brake assembly

A kind of technology of elastic retaining ring for holes and automobile front axle, which is applied in the direction of manufacturing tools, vehicle parts, metal processing, etc., can solve the problems of incomplete installation into the shaft groove, the safety of bearing detachment, and missing installation, so as to reduce the artificial The effect of engagement, improved accuracy, strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings:

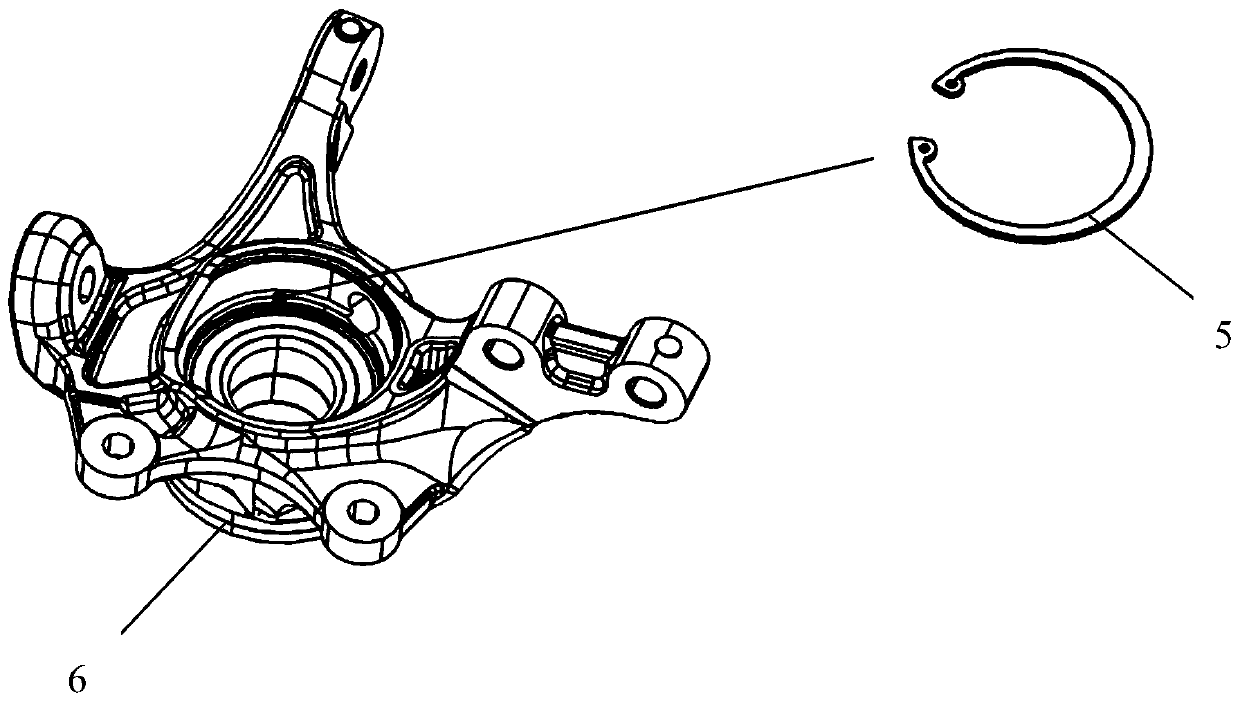

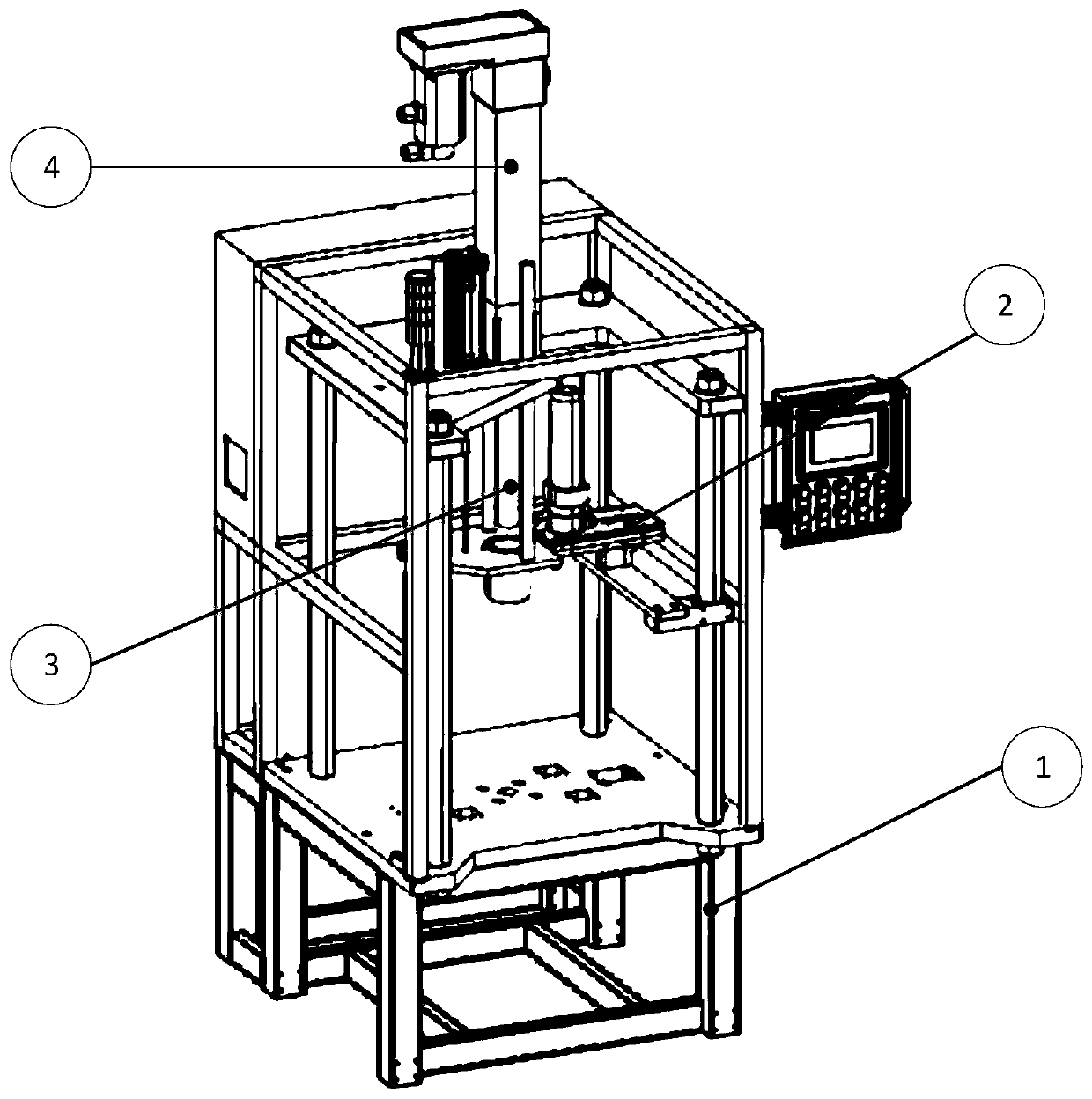

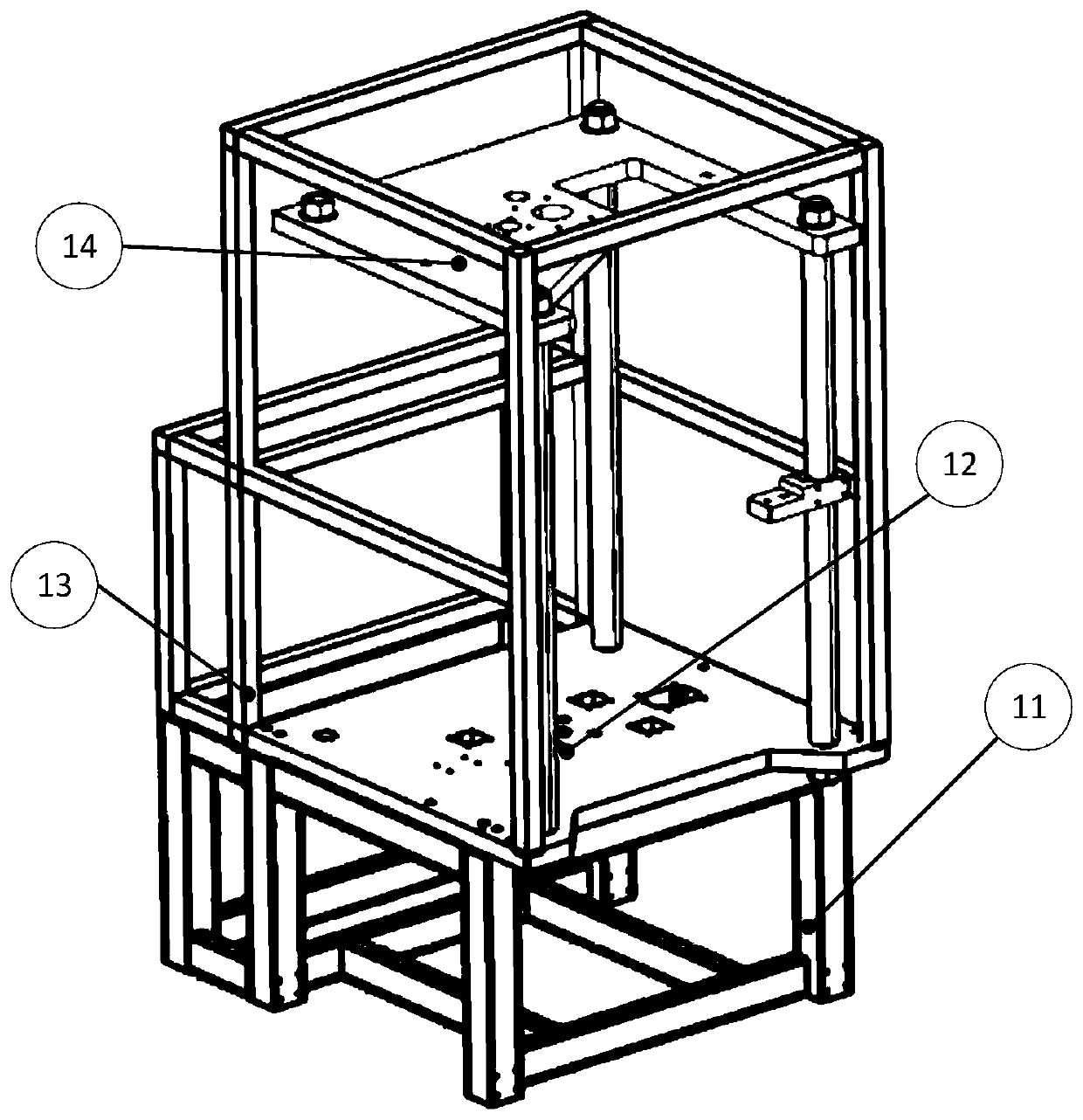

[0020] As shown in the figure, the automatic circlip automatic feeding mechanism for the hole of the automobile front axle brake assembly mainly includes the frame 1, the feeding device 2, the guiding device 3 and the pressing device 4, the feeding device 2, the guiding device 3 and the pressing device. The mounting device 4 is installed on the frame 1, the frame 1 plays a supporting and fixing role, the feeding device 2 realizes the elastic retaining ring 5 for the hole and feeding, and the guiding device 3 realizes the compression of the elastic retaining ring 5 for the hole to ensure the elasticity of the hole The retaining ring 5 can be smoothly pressed into the shaft groove of the steering knuckle 6, and the press-fitting device 4 can press the elastic retaining ring 5 for hole into the shaft groove of the steering knuckle 6, and read and display the pressing force and displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com