Fresh tobacco leaf stalk sectioning and orderly-clamping device and sectioning and clamping method thereof

A technology of fresh tobacco leaves and petioles, applied in tobacco, tobacco treatment, application, etc., can solve the problems of different degrees of drying, affecting the quality of flue-cured tobacco, and low efficiency of flue-cured tobacco, so as to achieve neat clipping on tobacco leaves, ensure the quality of flue-cured tobacco, and shorten the time of flue-cured tobacco Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

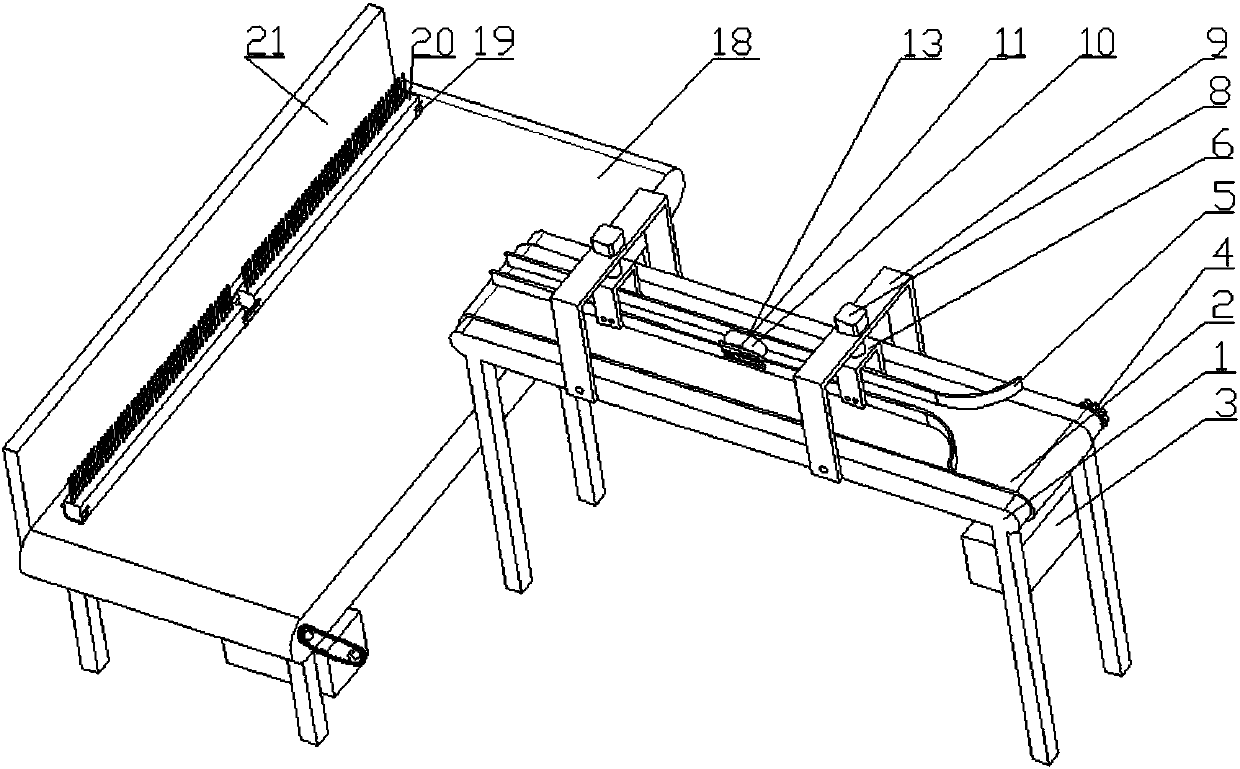

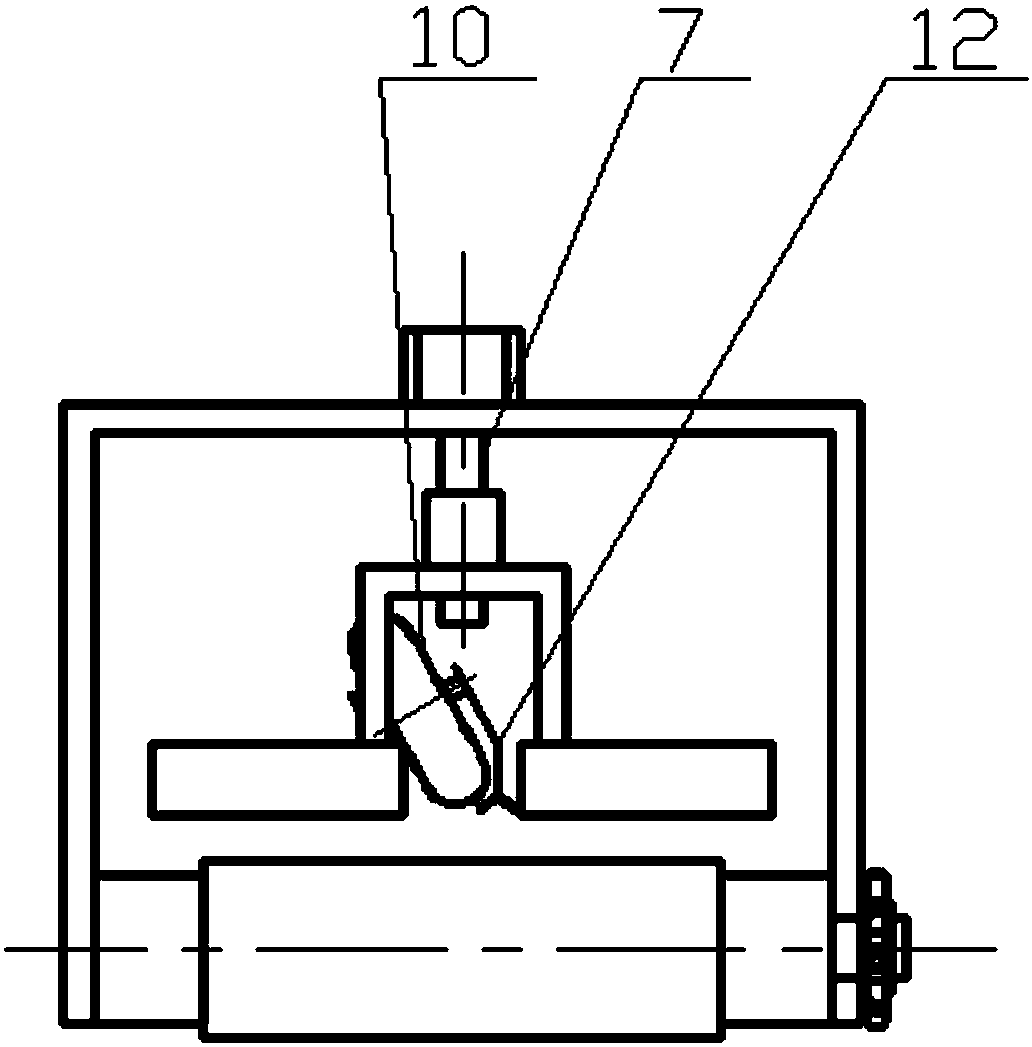

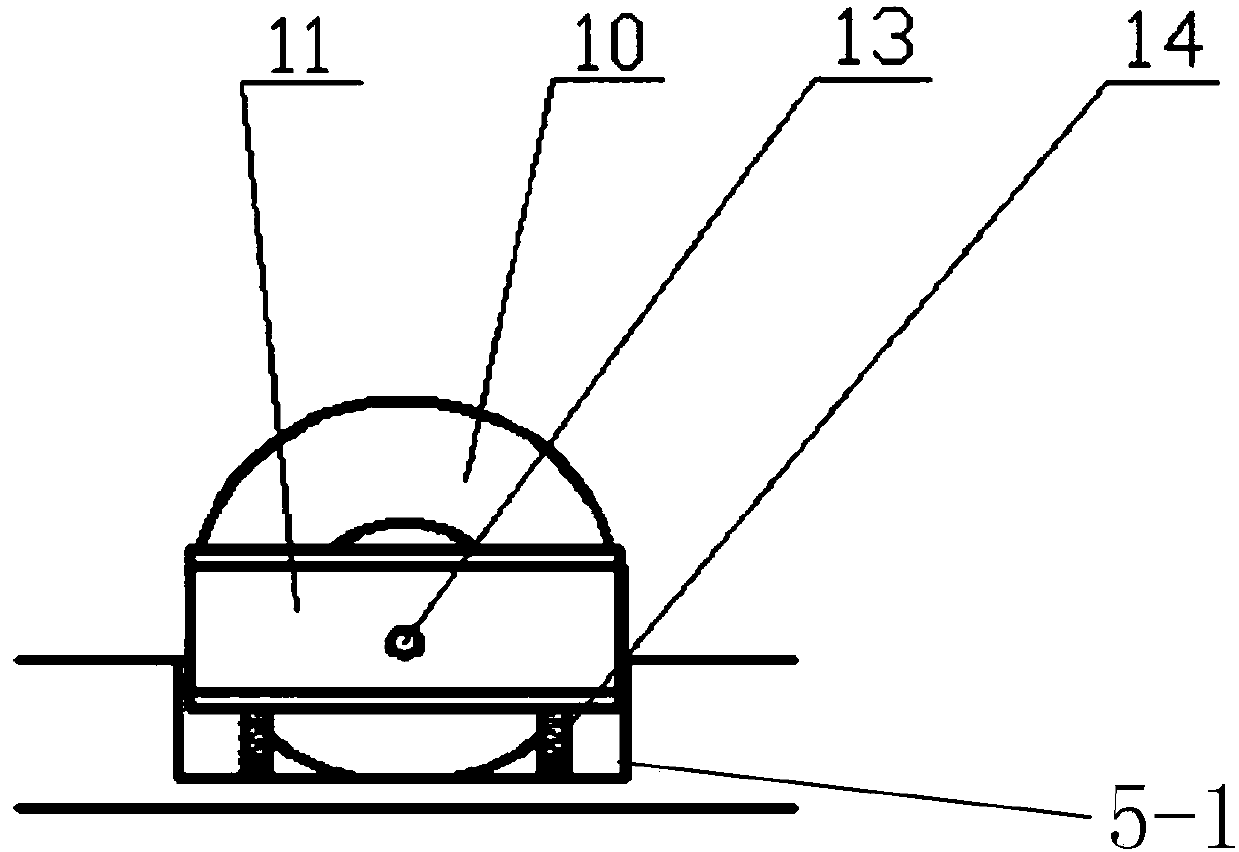

[0027] Such as figure 1 As shown, the fresh tobacco leaf petiole cutting and orderly clamping device includes a cutting device and an orderly clamping device; the cutting device includes a positioning assembly, a first belt transmission mechanism 2, a driving motor 3, and a first chain transmission mechanism 4. Guide plate 5, pressing profiling wheel 10, Y-shaped cutter 12 and photoelectric sensor 15; two position adjustment components are arranged at intervals along the transmission direction of the first belt transmission mechanism 2; position adjustment components include screw mandrel frame 6, wire Rod 7, position adjustment motor 8 and support 9; support 9 is fixed on the frame 1; position adjustment motor 8 is fixed on the support 9, and drives the screw mandrel 7; the top of the screw mandrel frame 6 and the screw mandrel 7 form a screw pair; The two guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com