Pulp dryer

A technology of a dryer and a driving mechanism, applied in the field of dryers, can solve the problems of wasting heat dissipation energy of the casing, difficult to grasp raw materials, and have a large impact on energy consumption, and achieves recovery of dehumidification capacity, increased air flow speed, and accelerated evaporation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

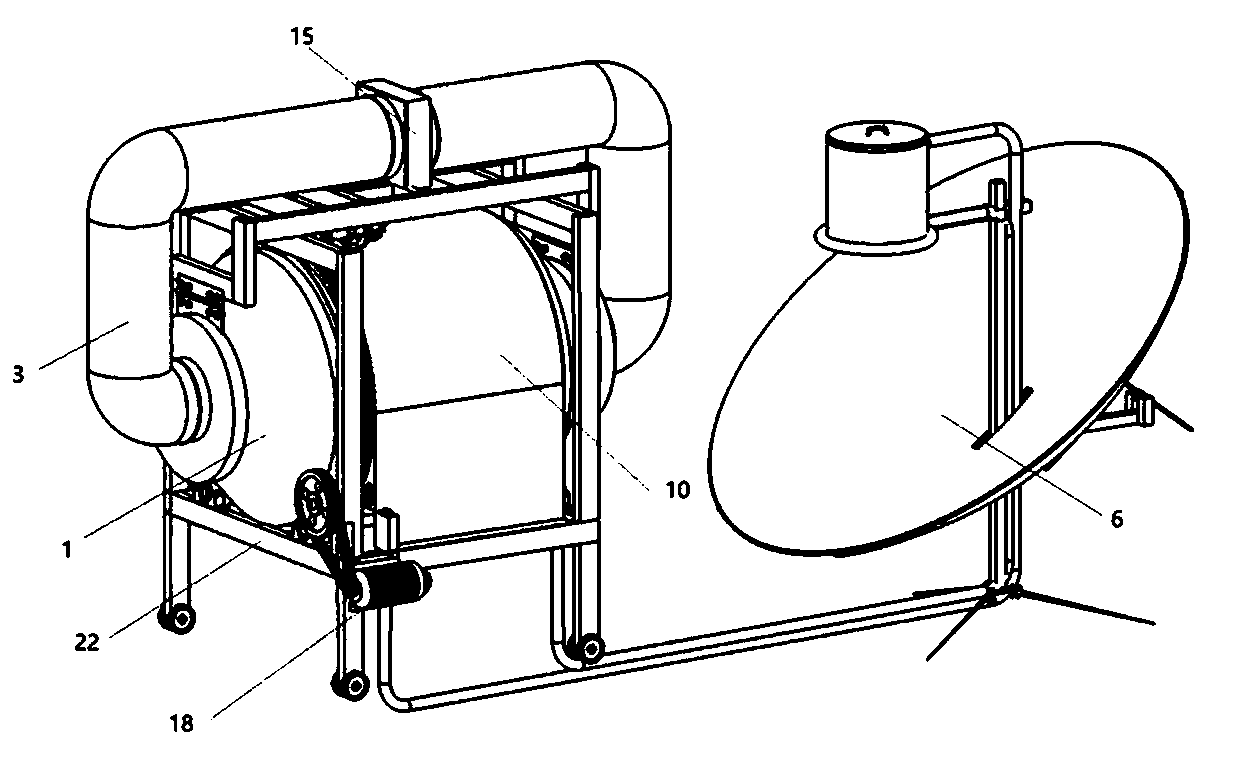

[0026] Such as Figure 1-Figure 5 Horizontal dryer shown, including drum assembly, circulating air supply assembly, heating assembly and dehumidification assembly,

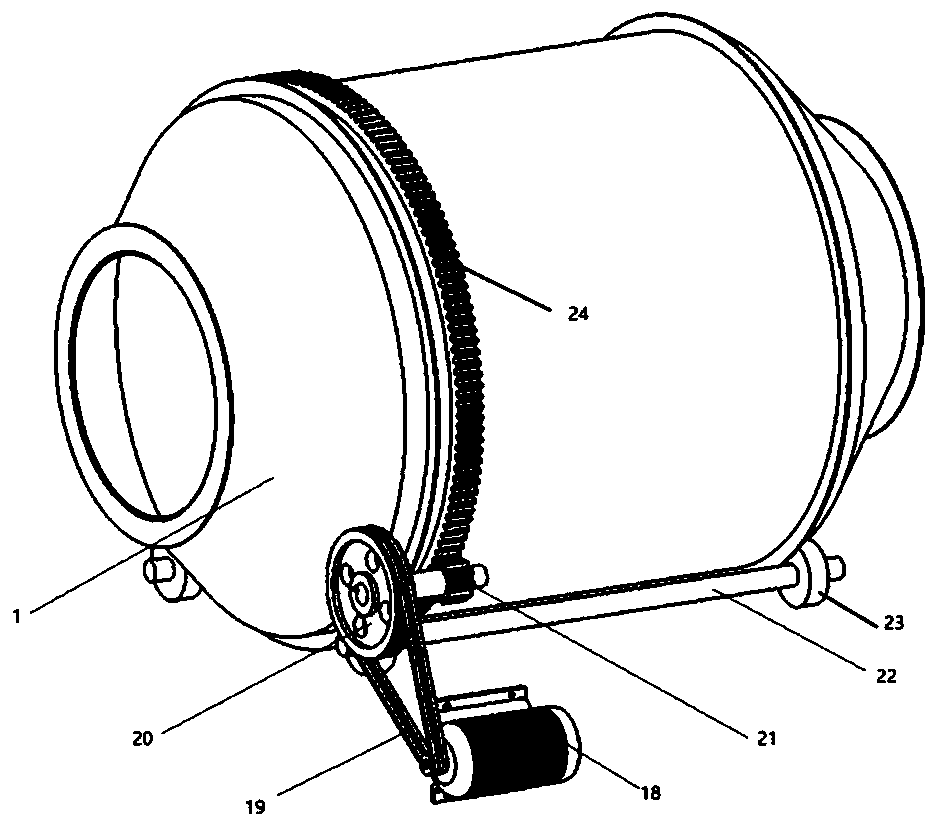

[0027] The drum assembly includes a driving mechanism and a horizontal drum 1, and the driving mechanism drives and connects the horizontal drum 1;

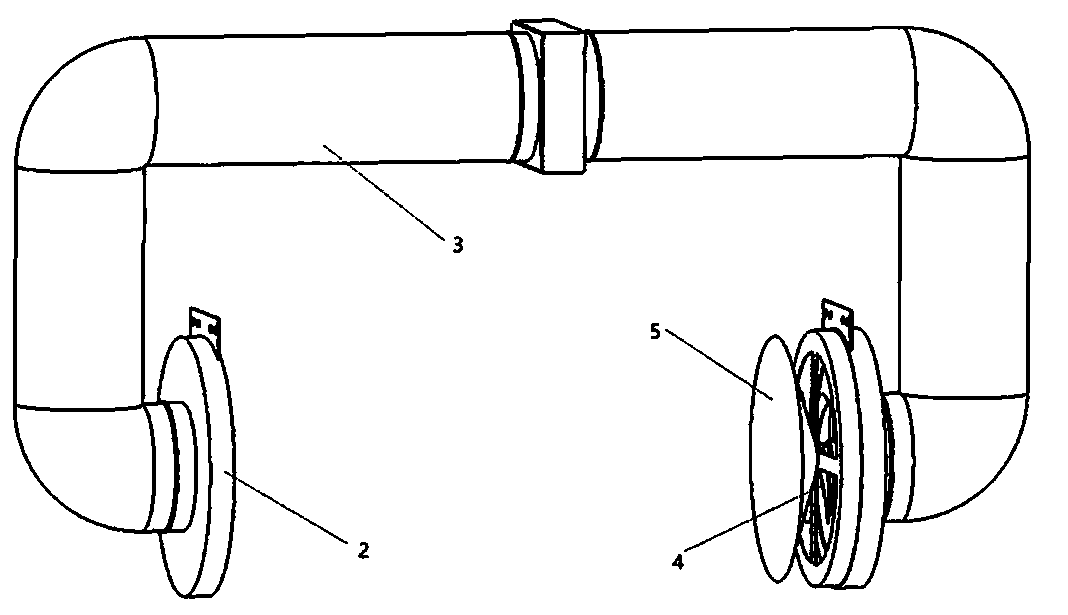

[0028] The circulating air supply assembly includes a drum cover 2, an air duct 3, a blower fan 4 and an air guide disc 5. The drum cover 2 covers the air outlet of the horizontal drum 1. The drum cover 2 is connected to the blower fan 4 through the air duct 3, and the air guide disc 5 is installed at the air outlet position of the blowing fan 4;

[0029] The heating assembly includes a solar panel 6, a solar heating tube 7, a heating power supply, a resistance wire heating tube 8, thermal insulation cotton 9 and a fixed cover 10, the solar panel 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com