Tea leaf withering system

A technology of tea and withering, which is applied in the field of tea processing machinery, can solve the problems of uneven water loss and uneven air temperature, which affect the effect of withering, etc., so as to speed up the air flow, meet the requirements of tea making technology, and speed up the process. The effect of wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

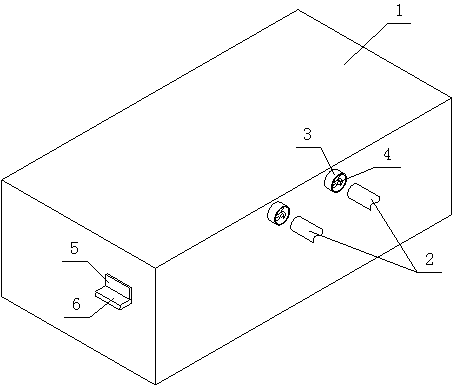

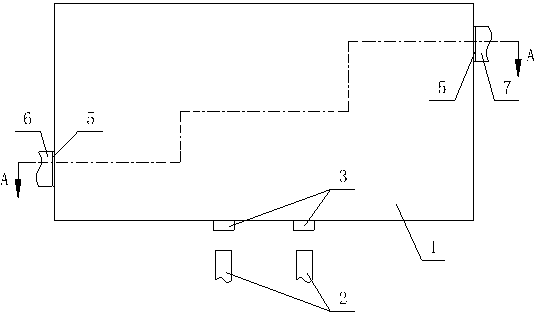

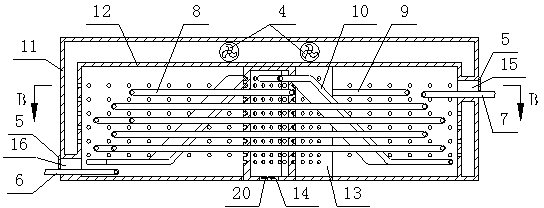

[0024] Such as Figure 1 to Figure 7 As shown, a tea withering system includes a hot blast stove, a withering room 1, a withering conveying structure, a tea inlet conveyor belt 6 and a tea outlet conveyor belt 7, and both the tea inlet conveyor belt 6 and the tea outlet conveyor belt 7 are existing structures , is mainly driven by the driving roller and the driven roller, and its specific structure will not be described here. Accompanying drawing of the present invention has only shown the part structure that enters tea conveyor belt 6 and goes out tea conveyor belt 7. The structure of the hot blast stove is not where the structural improvement of the present invention is, so any hot blast stove that can be used for the withering of tea leaves can be used. Accompanying drawing of the present invention has only shown the air outlet pipe 2 part of the blast stove relevant to the improvement of the present invention.

[0025] The withering room 1 is composed of an outer room 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com