Dried bean curd frying device

A technology of dried tofu and oil tank, applied in oil/fat roasting, roasting, food science and other directions, can solve the problems of low safety, high labor intensity, manual feeding, discharging and turning, etc., to achieve low labor intensity, avoid Good effect of adhesion and work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

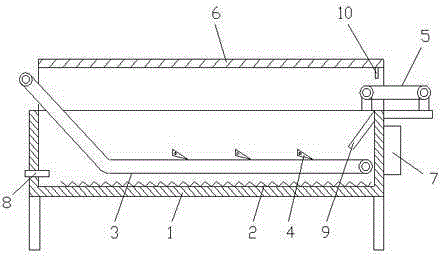

[0012] As shown in the figure, the dried tofu frying device of this embodiment includes an oil tank 1, an electric heater 2 and a metal belt conveyor 3 are arranged in the oil tank, and the discharge end of the metal belt conveyor is folded upwards obliquely. Bent out of the oil tank, the oil tank is also provided with a shoveling plate 4, the shoveling plate is rotatably installed on the oil tank through the rotating shaft, and the edge of the shoveling plate leans against the metal belt conveyor under the action of its own weight ; It also includes a feed conveyor 5 for feeding into the oil tank, a tank cover 6 arranged on the oil tank, and a controller 7 for controlling electric heaters, metal belt conveyors and feed conveyors.

[0013] The dried tofu frying device of this embodiment, when working, it sends the dried tofu into the oil tank through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com