Automatic cover finishing machine

An automatic sorting and cover technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low work efficiency and high labor intensity, achieve fast sorting speed, improve work efficiency, and be suitable for large-scale industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

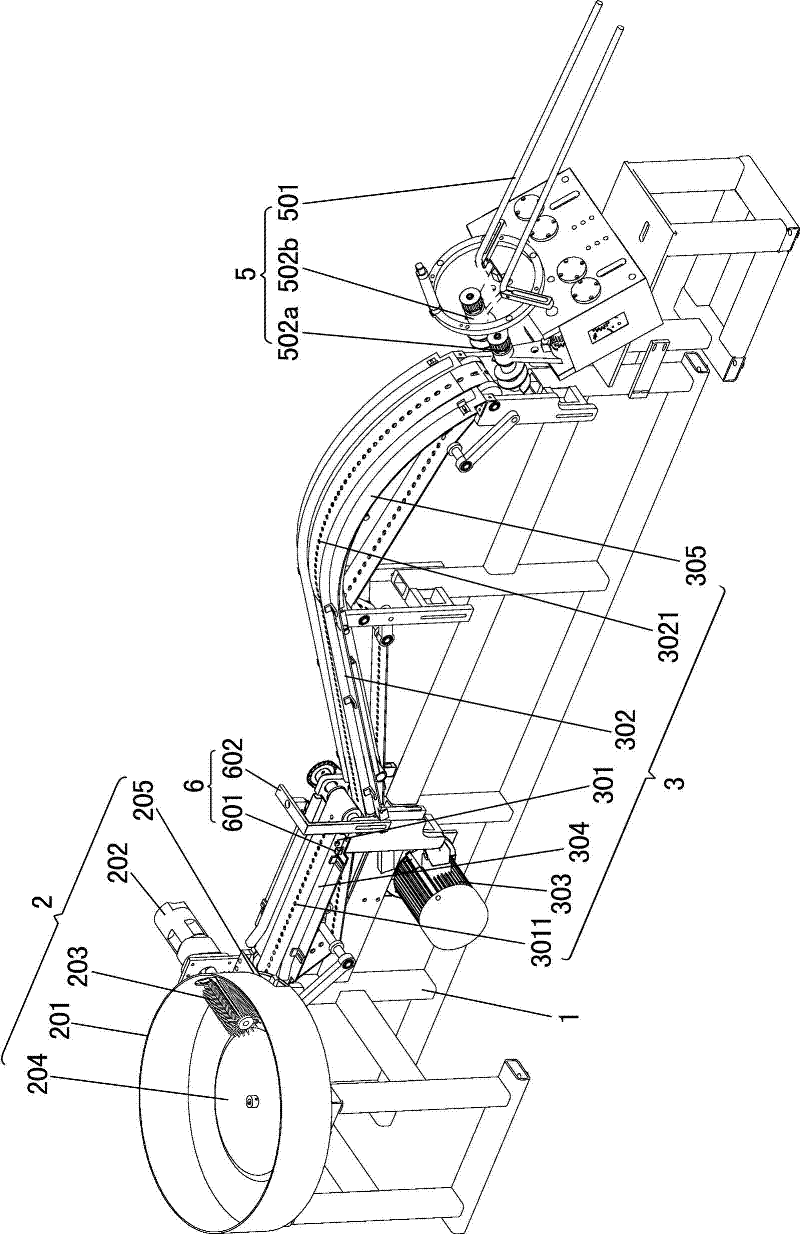

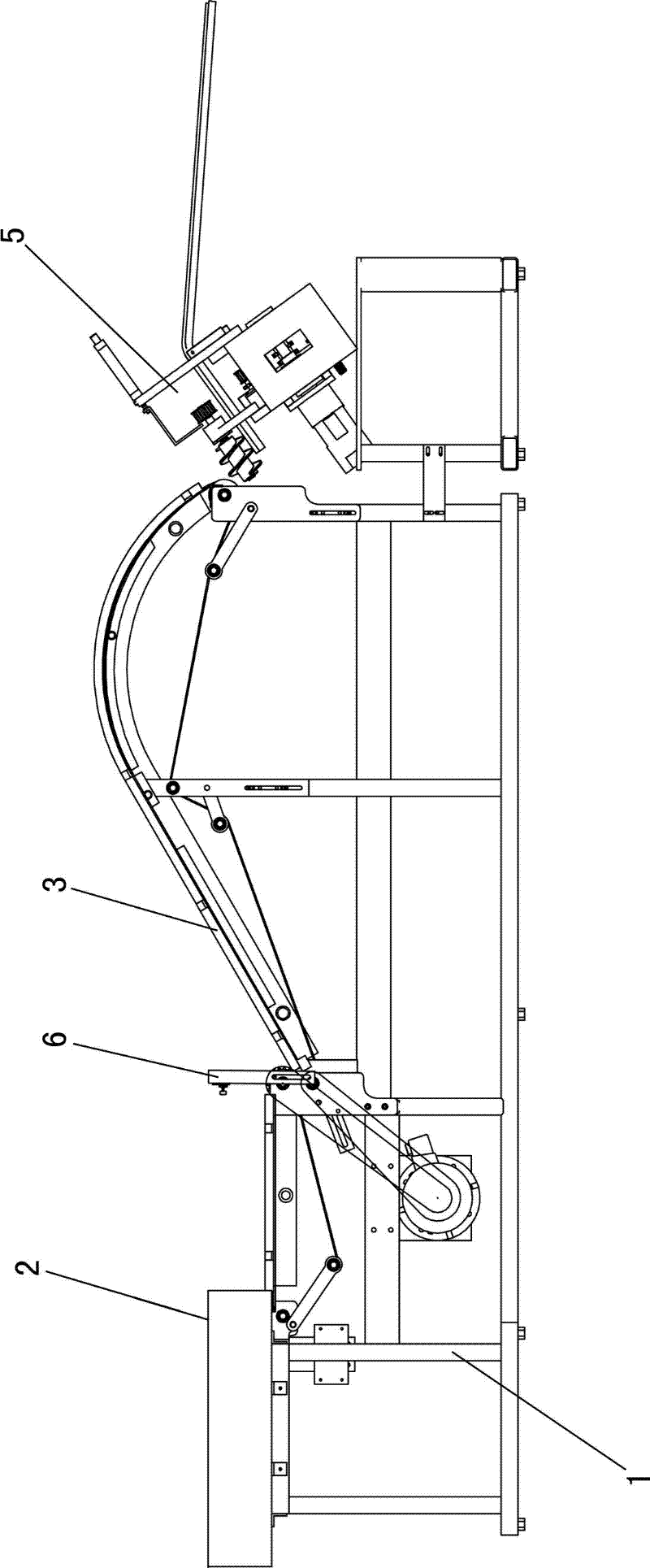

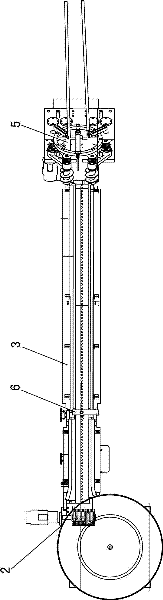

[0024] Such as Figure 1-3 As shown, the lid automatic finishing machine in this preferred embodiment includes a frame 1, a lid distribution mechanism 2, a lid transmission mechanism 3, a lid detection and turning mechanism 6, and a lid stacking mechanism 5. The lid distribution mechanism 2 and the lid transmission mechanism 3. The cover detecting and turning mechanism 6 and the cover stacking mechanism 5 are fixed on the frame 1 respectively.

[0025] Described lid dispensing mechanism 2 comprises lid storage groove 201, motor 202, distribution brush 203, centrifugal rotating disk 204 and rotating disk driving mechanism (not shown), and described storage lid groove 201 is circular, and the side bottom of storage lid groove 201 There is a cover output port 205 at the end, the inlet of the cover transfer mechanism is connected to the cover output port 205, the centrifugal turntable 204 is rotatably fixed on the bottom surface of the cover storage tank 201, the turntable drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com