Method and device for turning over bamboo chips used for summer sleeping mat

A technology of bamboo chips and mats, which is applied in the manufacture of thin wood chips, multi-purpose machinery, wood processing appliances, etc., can solve the problems of small radian of green surface, whether the detection is accurate, small color difference, etc., and achieves easy implementation, unique method and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for turning over bamboo slices for a summer mat. The bamboo slices to be drilled or woven for flower arrangement are placed in a container filled with liquid. The liquid is in a static state or a flowing state (this embodiment is in a static state), and The specific gravity of the bamboo slices is greater than that of the bamboo slices, and the bamboo slices rise to the surface of the liquid under the action of buoyancy. Because the green and yellow sides of the bamboo slices have different specific gravity, the bamboo slices turn over during the rising process, so that the bamboo slices floating on the liquid surface The yellow side faces up and the blue side faces down.

[0026] In order to ensure the reliability and accuracy of turning over the bamboo slices, the specific gravity of the liquid described in the present invention is at least 1.1 times of the specific gravity of the bamboo slices.

[0027] Because the specific gravity of the bamboo chip is less...

Embodiment 2

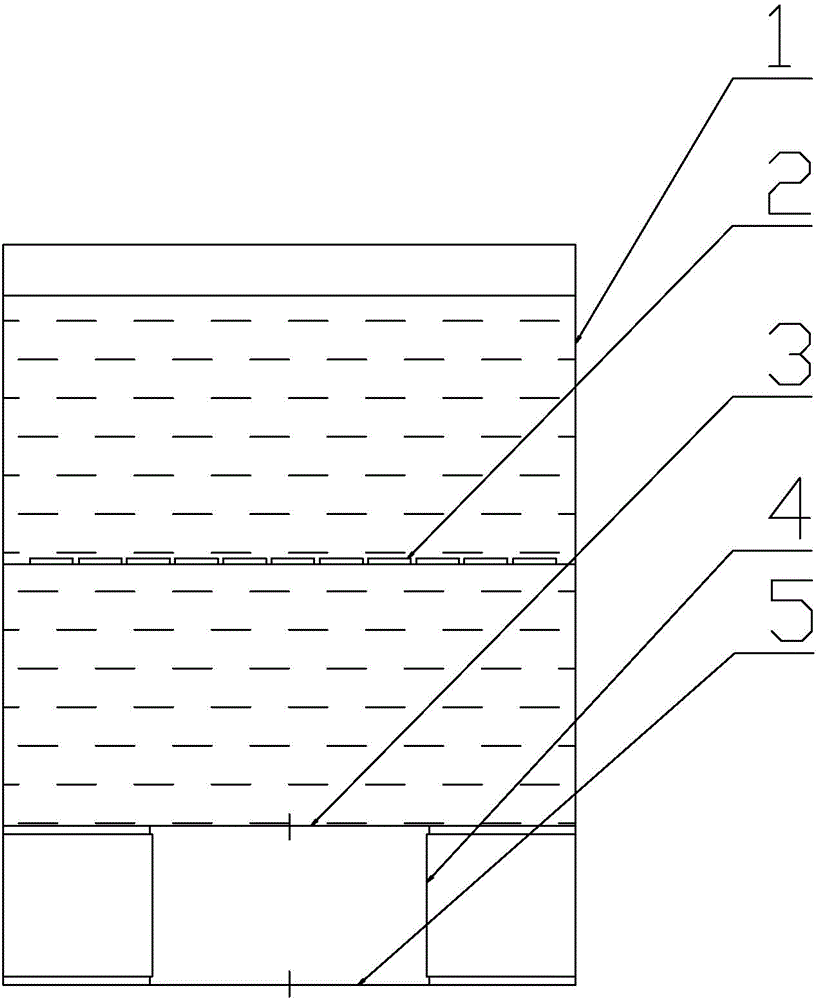

[0035] The opening of the material box 4 of the present invention faces the surface of the liquid.

[0036] For the convenience of feeding, when feeding, it is not necessary to discharge all the water in the container 1. The bottom or side of the feed box 4 of the present invention is provided with a feed port, and the feed port of the feed case 4 is provided with an openable or Closed feed plate 5.

[0037] During use, earlier with seal plate 3 the opening of feed box 4 is closed, then open feed plate 5 at the bottom of feed box 4, discharge the water of feed box 4, put into bamboo chip again, close feed plate 5 and get final product.

[0038] The rest are the same as embodiment 1.

Embodiment 3

[0040] For simple structure, the material box 4 of the present invention is installed on the container 1 through a pin shaft, so that the material box 4 can rotate around the pin shaft.

[0041] During use, when the opening of the material box 4 faces the surface of the liquid, the sealing plate 3 is opened to realize discharging; Towards the surface of the liquid, put the bamboo chips, then rotate the feed box 4, so that the opening of the feed box 4 faces the surface of the liquid, and circulate like this.

[0042] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com