Automatic liquid shampoo canning device

A shampoo, automatic technology, applied in liquid bottling, packaging, bottling machines, etc., can solve the problems of inconvenient filling, easy to breed bacteria, and take a long time, saving the time of capping and pressing , Improve the efficiency of stamping and pressing, and save the time of manual transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A shampoo automatic canning device, such as figure 1 As shown, it includes a bottom plate 1, a frame 2, an extruding mechanism 4 and a transport mechanism 5. The left part of the bottom plate 1 is provided with a frame 2, the bottom plate 1 is provided with a transport mechanism 5, and the frame 2 is provided with an extruding mechanism 4. .

[0090] When people need to fill the material 3, the material 3 is placed on the transport mechanism 5, and the extruding mechanism 4 is filled with shampoo at the same time, and then the extruding mechanism 4 is started, and the extruding mechanism 4 drives the transport mechanism 5 to move , in the process of conveying the material 3, the extruding mechanism 4 cans it, and after the canning is completed, the extruding mechanism 4 is closed, and the transport mechanism 5 stops moving.

Embodiment 2

[0092] On the basis of Example 1, such as figure 2 As shown, the extrusion mechanism 4 includes a servo motor 41, a first transmission shaft 42, a cam 43, a piston 44, a first spring 45, an extrusion cylinder 46, a one-way valve 47, a material pipe 48, a material barrel 49 and a barrel cover 410, the frame 2 is provided with a servo motor 41, the top of the frame 2 is connected with a first transmission shaft 42 in a rotational manner, the first transmission shaft 42 is connected with the output shaft of the servo motor 41, and the right part of the first transmission shaft 42 is provided with a cam 43 The middle part of the frame 2 is provided with an extruding cylinder 46, the bottom of the extruding cylinder 46 is provided with a one-way valve 47, the top of the extruding cylinder 46 is slidably connected to a piston 44, and the first spring is connected between the extruding cylinder 46 and the piston 44. 45, the lower part of the extruding barrel 46 is provided with a fe...

Embodiment 3

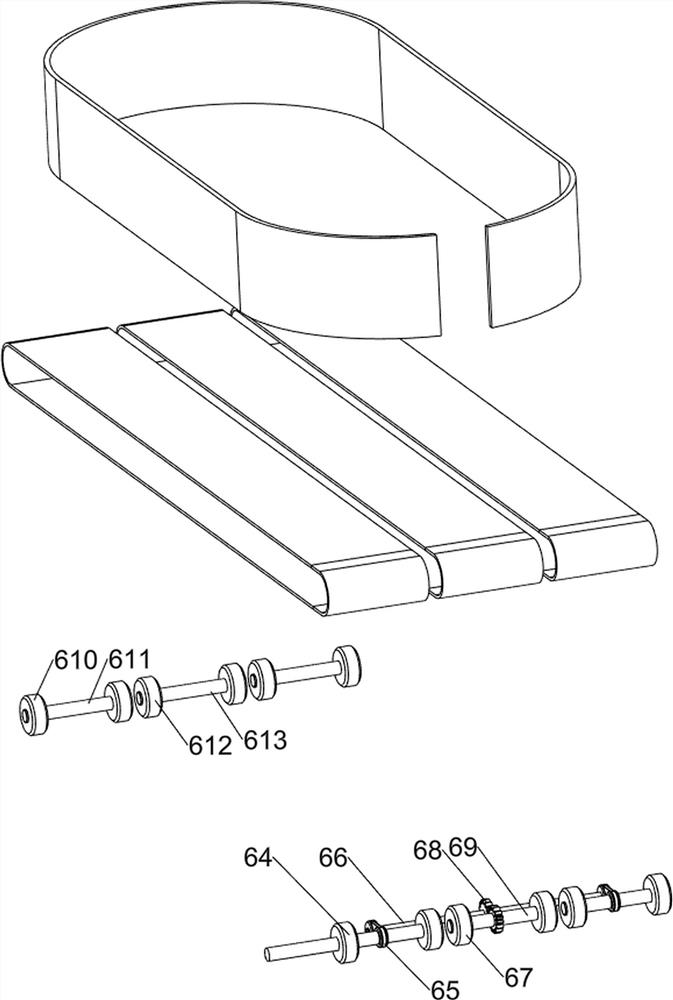

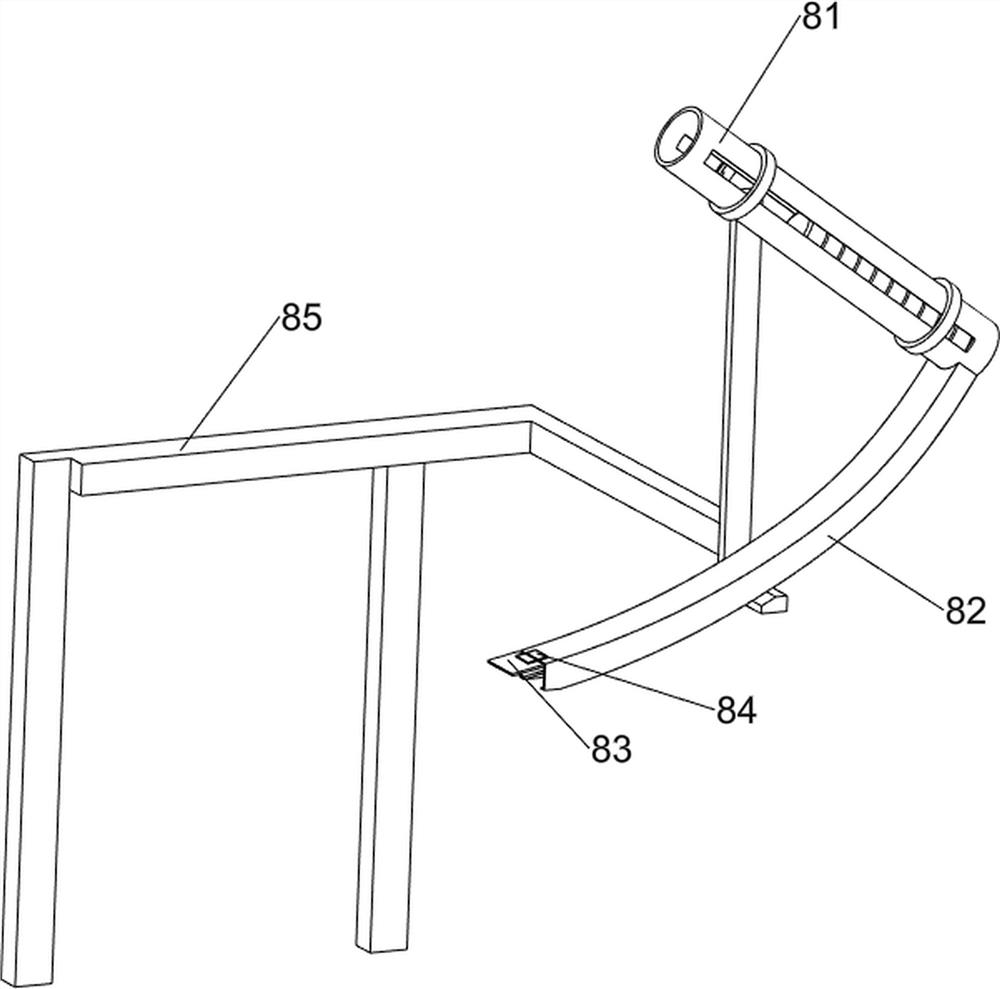

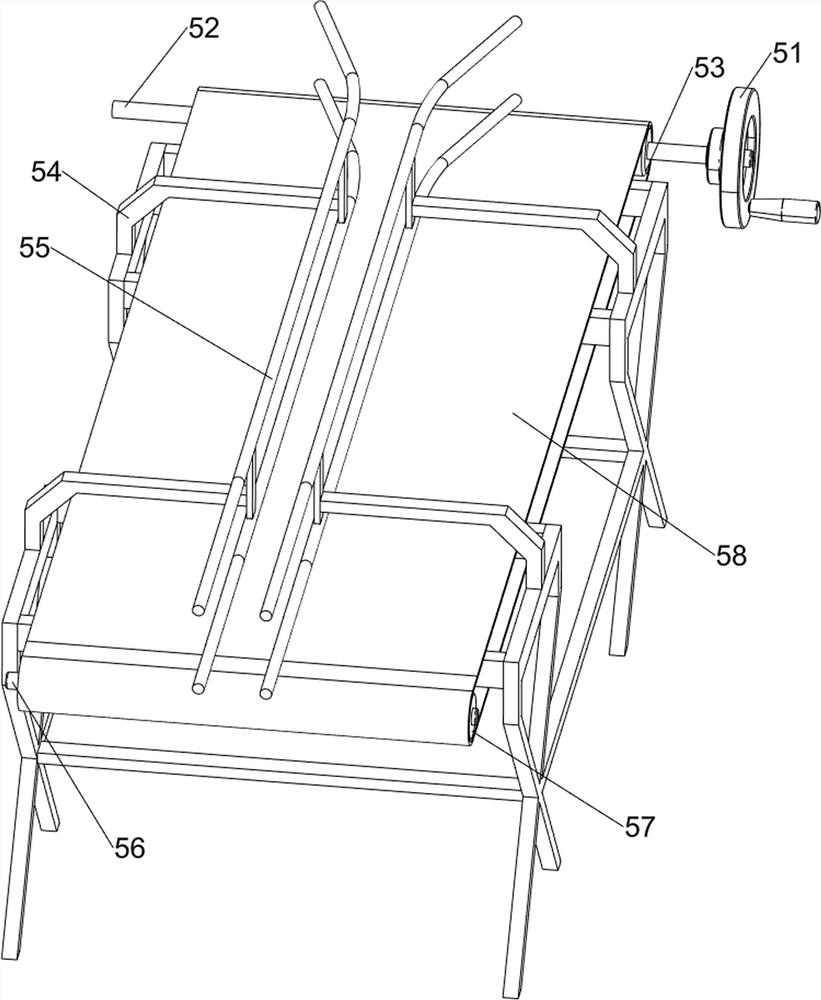

[0095] On the basis of Example 2, such as Figure 3 to Figure 8 As shown, the transportation mechanism 5 includes a handle 51, a second transmission shaft 52, a first transmission wheel 53, a conveyor belt frame 54, a guide frame 55, a third transmission shaft 56, a second transmission wheel 57 and a first transmission belt 58, and the bottom plate 1 The front portion is provided with a conveyor belt frame 54, on which the conveyor belt frame 54 is provided with a guide frame 55, and the front portion of the conveyor belt frame 54 is rotatably connected with a third drive shaft 56, and 4 second transmission wheels 57 are evenly distributed on the third drive shaft 56 , the conveyor belt frame 54 rear portion is rotatably connected with a second transmission shaft 52, and the second transmission shaft 52 is evenly distributed with 4 first transmission wheels 53, and the right side of the second transmission shaft 52 is provided with a handle 51, and the second transmission wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com