Automatic stock cutter for nibs

A material cutting machine and automatic technology, applied in metal processing and other directions, can solve the problems of low accuracy, low efficiency, and prone to safety accidents, and achieve the effect of orderly discharging process, prolonging the use time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

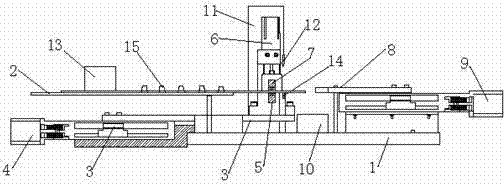

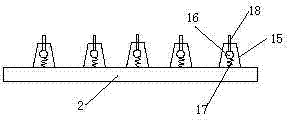

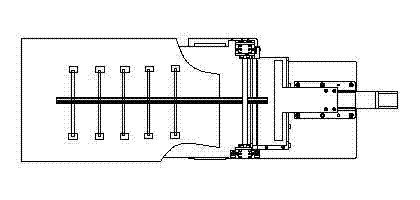

[0014] Combine below Figure 1 to Figure 3 Specific description embodiment:

[0015] An automatic cutting machine for nibs, comprising a frame 1, the frame 1 is provided with a discharge plate 2, and the frame 1 is provided with a slide plate 3 below the discharge plate 2, and the slide plate One end of 3 is connected with electric cylinder 4, and the other end of described slide plate 3 is fixed with lower roller 5, and described slide plate 3 is positioned at the both sides of lower roller 5 and is provided with cylinder 6, and described cylinder 6 is connected with upper roller 7, so The upper roller 7 can be clamped and fed with the lower roller 5 under the action of the cylinder 6; the frame 1 is provided with a sliding limiting plate 8, and the sliding limiting plate 8 is connected with a fixed-length motor 9; The frame 1 is positioned between the sliding limit plate 8 and the lower roller 5 and is provided with an unloading chute 10; the frame 1 is provided with a stam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com