Intermittent feeding assembly device of cement mixing tank and production method thereof

A mixing tank and cement technology, which is applied in mixing plants, control devices, clay preparation devices, etc., can solve problems such as feeding blockage, affecting production progress, and feeding confusion, so as to avoid feeding blockage, improve production efficiency, and mix even and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

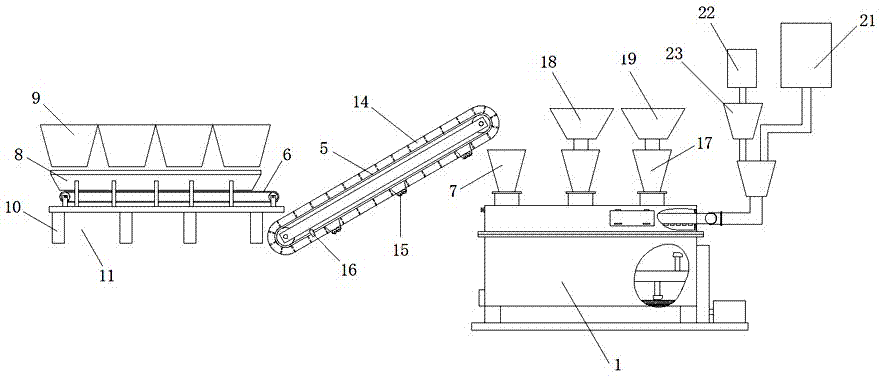

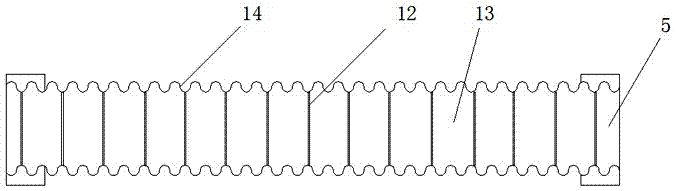

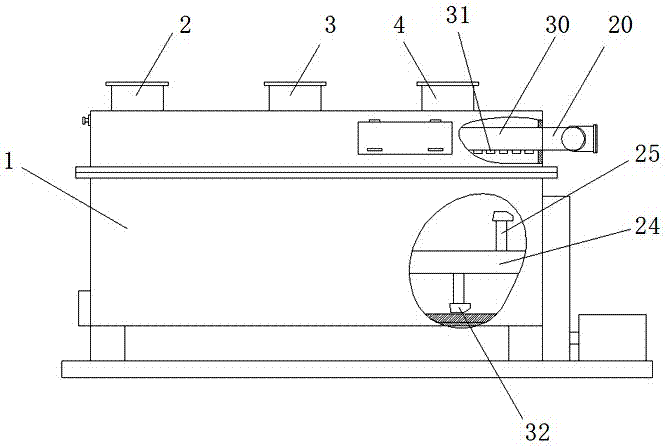

[0019] like Figure 1~4 As shown, a cement mixing tank intermittent feeding assembly device includes a cement mixing tank 1, and the top of the cement mixing tank 1 is provided with an aggregate feeding port 2, a cement feeding port 3 and a powder feeding port 4, and the cement mixing tank The tank 1 side is provided with a liquid inlet 20; it also includes an oblique feeding inclined belt 5 and a horizontally arranged flat belt 6, and a transition bin 7 is arranged above the aggregate feeding port 2, and the feeding inclined belt 5 exits The feed end is located above the transition bin 7, the discharge end of the flat belt 6 is located above the feed end of the feeding inclined belt 5, and above the flat belt 6 is provided with a long groove-shaped aggregate 8 arranged along the length direction of the flat belt 6. A plurality of aggregate bins 9 for storing aggregates are arranged above the scale 8 along the length direction of the aggregate scale. Aggregate of different thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com