Automatic sorting equipment for pearls

An automatic sorting and equipment technology, applied in sorting and other directions, can solve the problems of high labor cost and low efficiency, and achieve the effect of low error rate, less error-prone and close cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings.

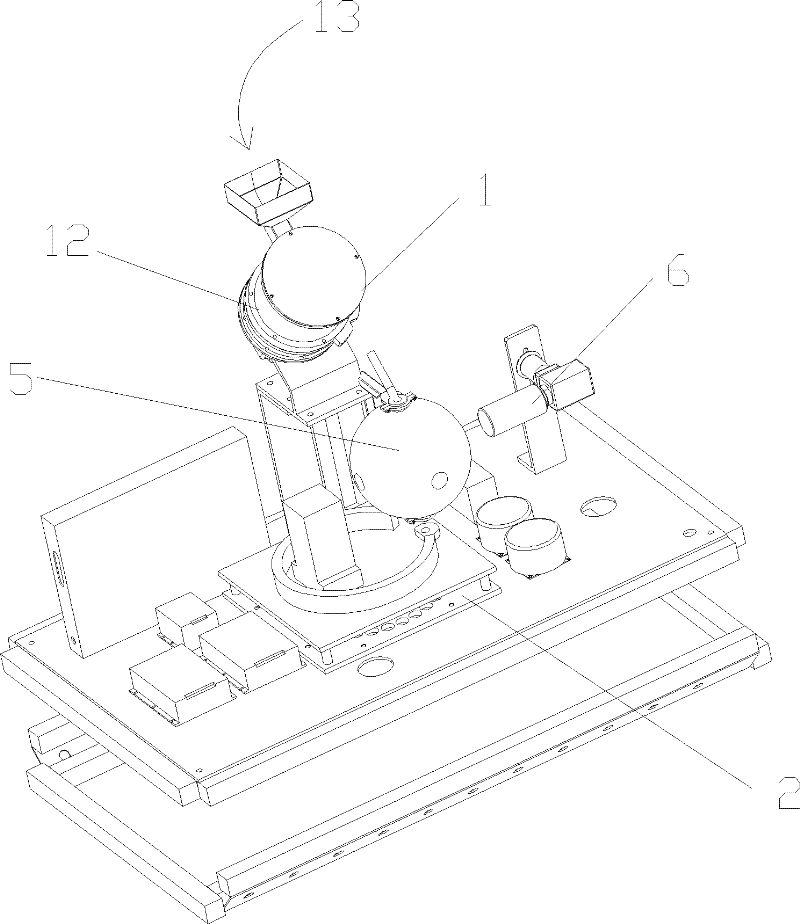

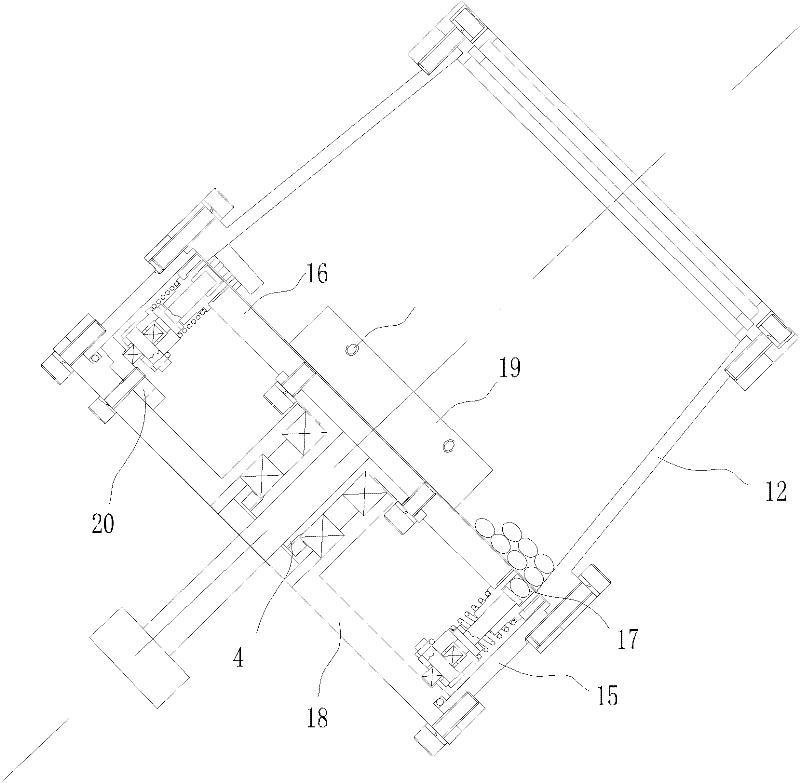

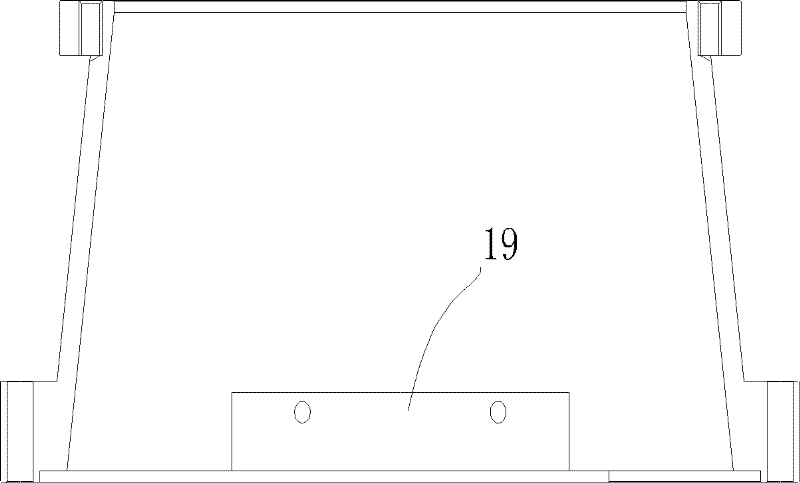

[0028] like Figure 1-12 As shown, a kind of pearl automatic sorting equipment described in this embodiment includes a feeding device 1 and a summarizing device 2 one by one. The feeding device 1 includes a feeding port 13 and a discharging port 14. The discharging port 14 is connected with a guide below, and a shooting area is set in the middle of the guide, and a light source 5 and a shooting device 6 are arranged on both sides of the shooting area, and the induction device 2 includes a plurality of storage boxes and a plurality of drop holes 3 , the lower end of the guide is matched with a falling hole 3 of the induction device 2, the photographing device 6 transmits the obtained photographing signal to a controller, and the controller analyzes the photographing signal through a sorting software Afterwards, corresponding instructions are sent to the induction device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com