Camellia oleifera seed sheller thorough in milling

A technology of Camellia oleifera seed shelling machine, which is applied in the direction of shelling, fat oil/fat production, and fat production, etc. It can solve the problems of low shelling efficiency, lack of crushing camellia seed shells, and inability to completely shell and break seeds. Achieve the effects of reducing the broken seed rate, avoiding repeated friction, and shortening the grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

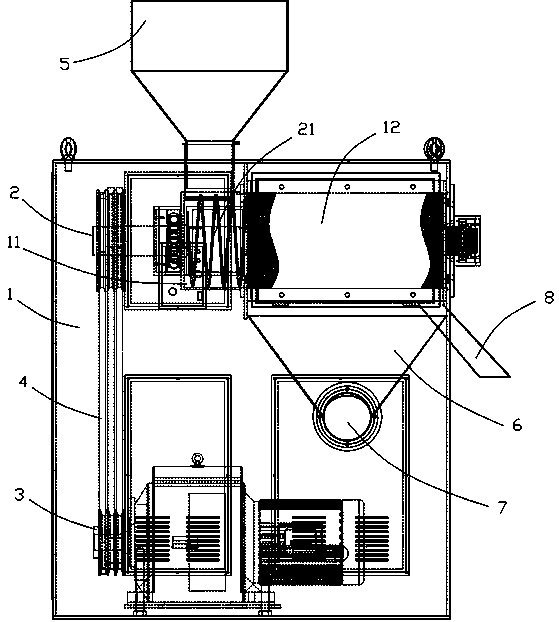

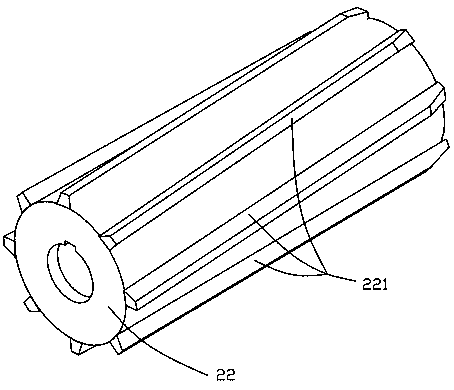

[0028] Such as figure 1 As shown, a thoroughly milled camellia seed shelling machine includes a frame 1, a rotating shaft 2 disposed in the frame and a driving device 3 for controlling the rotation of the rotating shaft. The driving device is an electric motor, and the shaft of the motor and the rotating shaft 2 Drive through the belt 4 between. The outer periphery of the first end of the rotating shaft 2 is provided with a spiral transmission structure 21. The spiral transmission structure 21 is a structure (similar to a screw rod) arranged on the rotating shaft 2 in a spiral winding type. Forward transmission to the grinding place, the outer circumference of the spiral transmission structure 21 is provided with a sleeve 11 fixed on the frame, and the outer circumference of the second end of the rotating shaft 2 is provided with a roller 22 (the roller is connected to the rotating shaft with a key). The cylinder 22 can rotate following the rotating shaft 2. The outer periphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com