Raw material grinding equipment for chemical machinery

A technology for chemical machinery and raw materials, applied in the field of raw material grinding equipment for chemical machinery, can solve the problems of easy sticking to the edge of the groove and incomplete grinding, and achieve the effect of complete grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

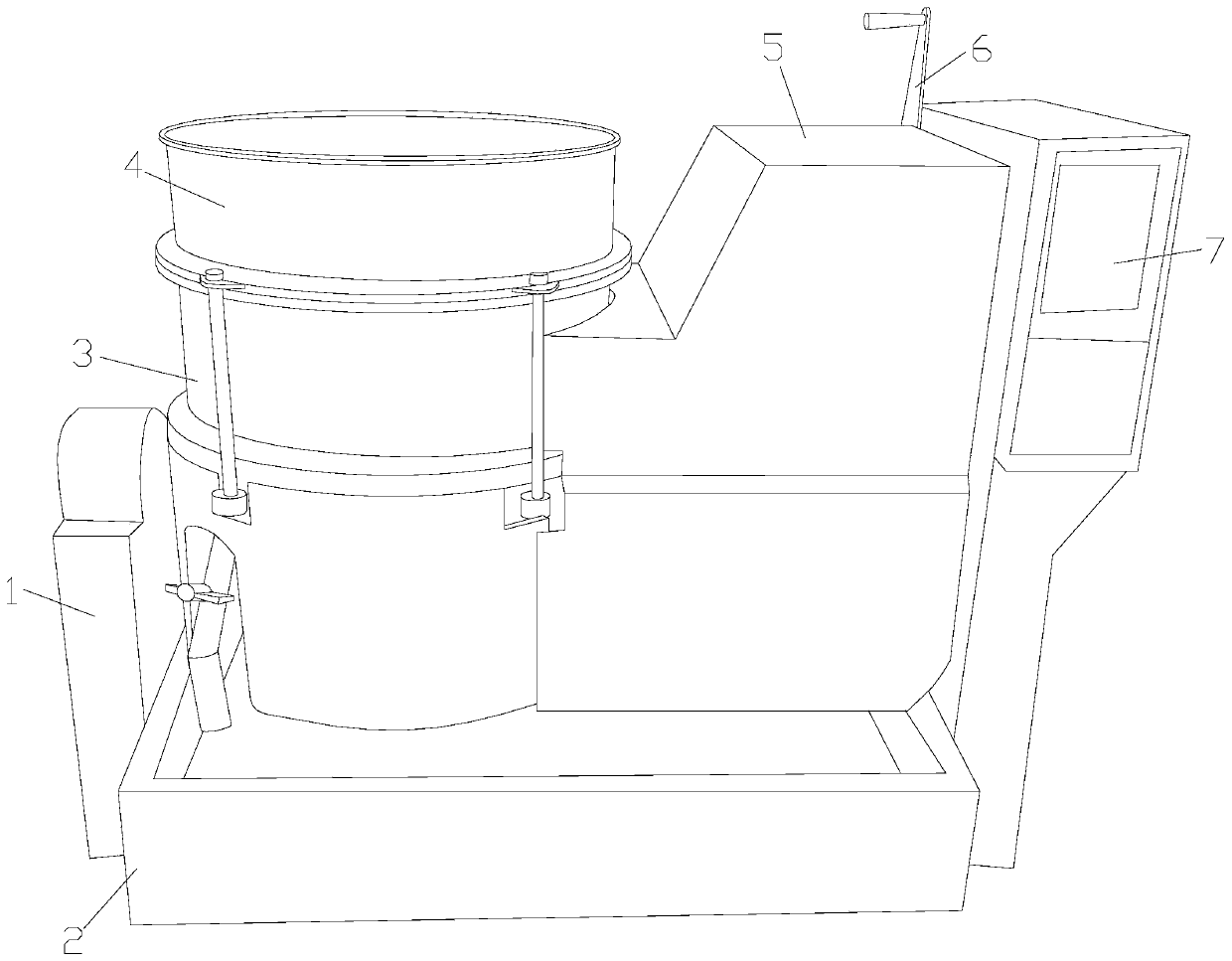

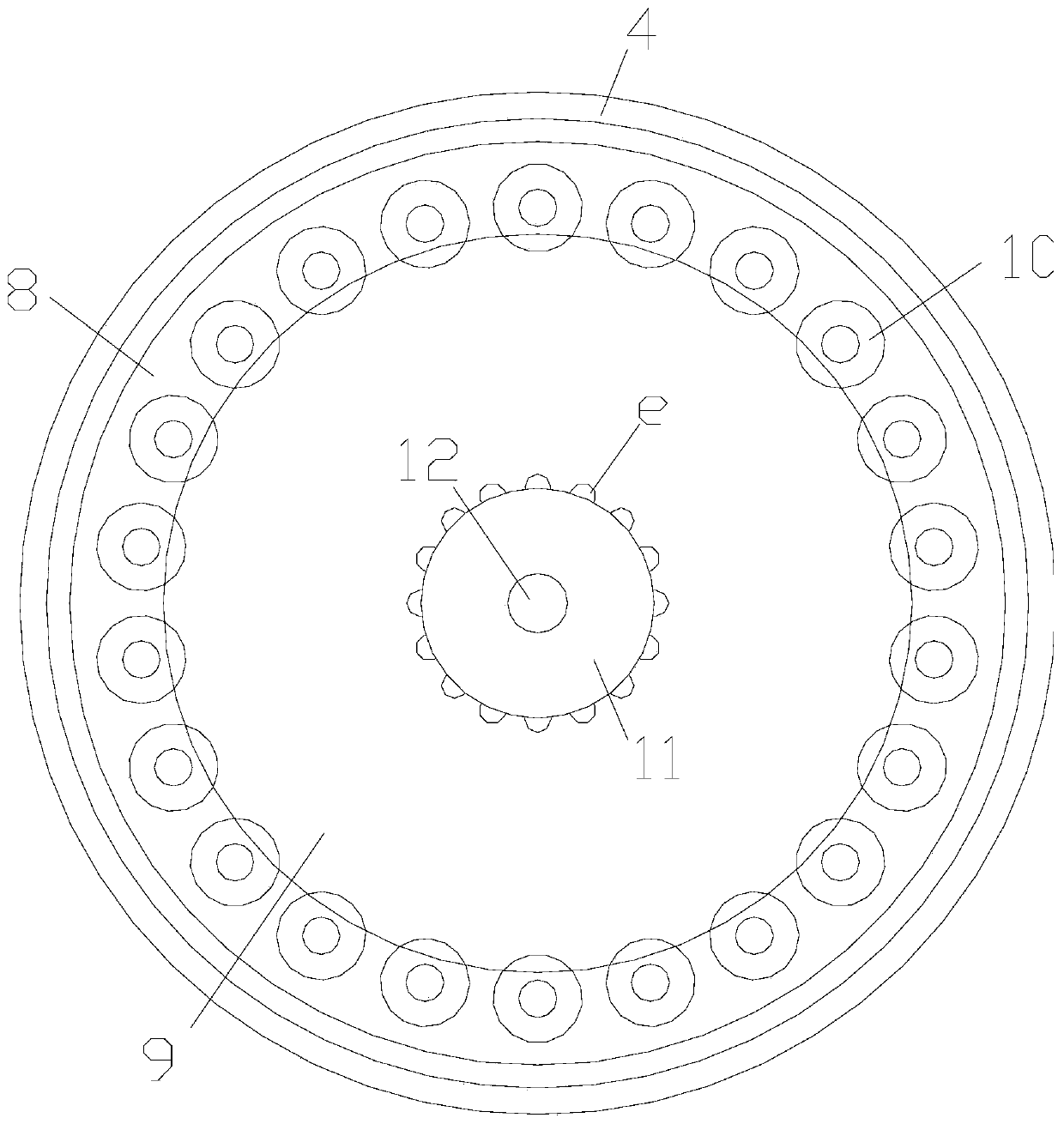

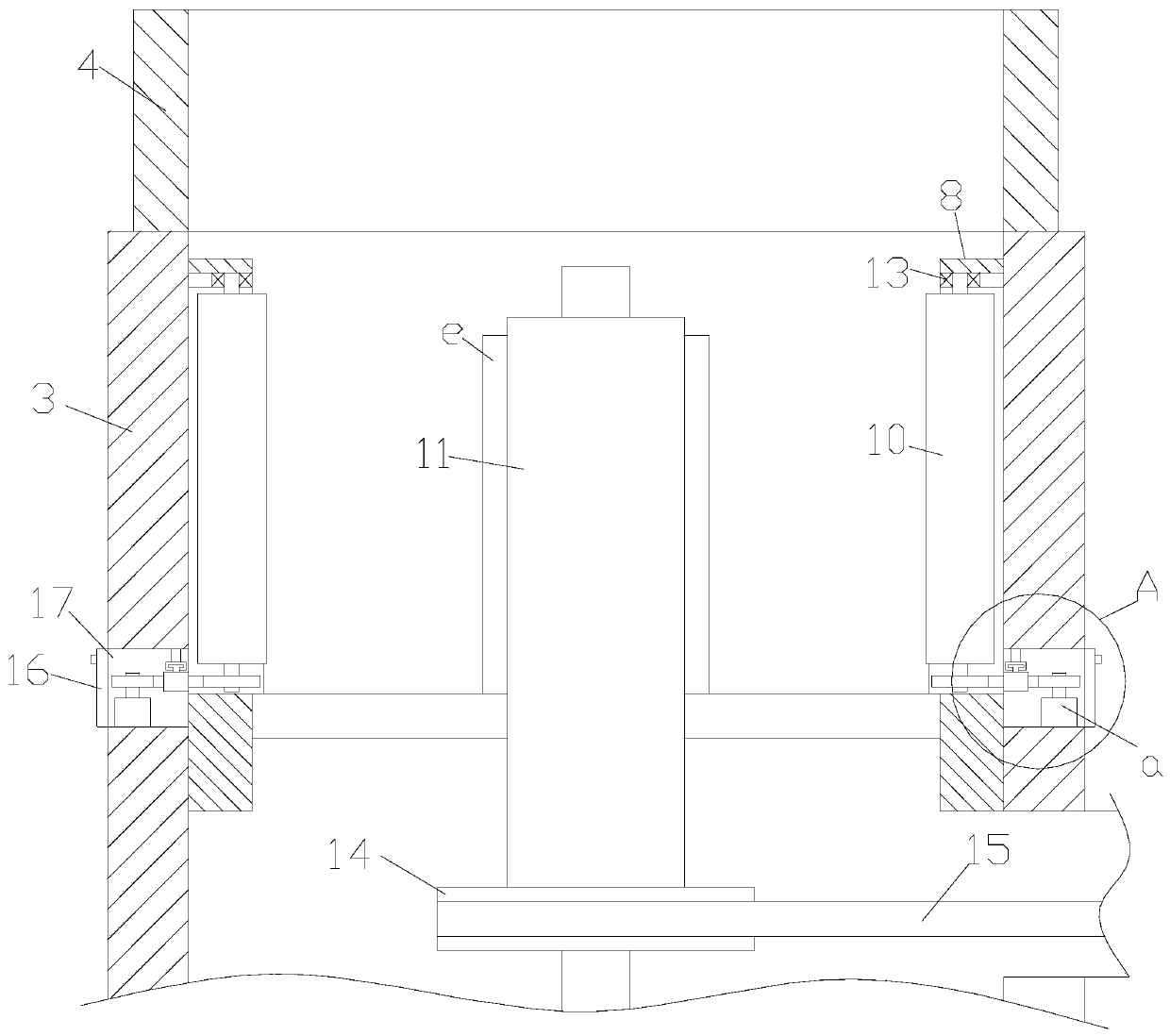

[0030] see Figure 1-Figure 5 , the present invention provides a technical solution for raw material grinding equipment for chemical machinery: its structure includes a frame 1, a water tank 2, a grinding cylinder 3, a top ring 4, a body 5, a rocker 6, and a control panel 7. The frame 1 The bottom of the body is equipped with a water tank 2, the body 5 is movably installed on the frame 1 and is located above the water tank 2, the grinding cylinder 3 is connected to the left side of the body 5, and the top ring 4 passes through four sets of The bolt rod is installed above the grinding cylinder 3, and the rocking lever 6 is installed on the rear end on the right side of the top of the body 5. A control panel 7 is arranged on the right column of the body 5; There is a ring sleeve 8, and twenty-two groups of grinding rollers 10 are equidistantly arranged in the ring sleeve 8, and a grinding groove 9 is arranged in the middle of the ring sleeve 8, and a cylinder 12 is connected in ...

Embodiment 2

[0033] like Image 6 As shown, on the basis of Embodiment 1, more than two grinding blocks f are evenly and equidistantly arranged on the roller surface of the grinding roller 10, and a central axis h passes through the middle of the grinding roller 10, and both One end of the central shaft h is in interference fit with the bearing seat 13, and the other end is connected with a driven gear c, and the driven gear c is meshed with the inner ring gear a5.

[0034] The driven gear c at the bottom of the grinding roller 10 rotates under the drive of the ring gear a5. The surface of the grinding roller 10 is provided with grinding blocks f. These grinding blocks f can grind the ceramic raw materials to make the ceramic raw materials grind more thoroughly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com