Tool for machining automobile sleeve

A technology for sleeves and automobiles, which is applied in metal processing equipment, grinding devices, manufacturing tools, etc., and can solve problems that affect subsequent use, burrs that cannot be removed, and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

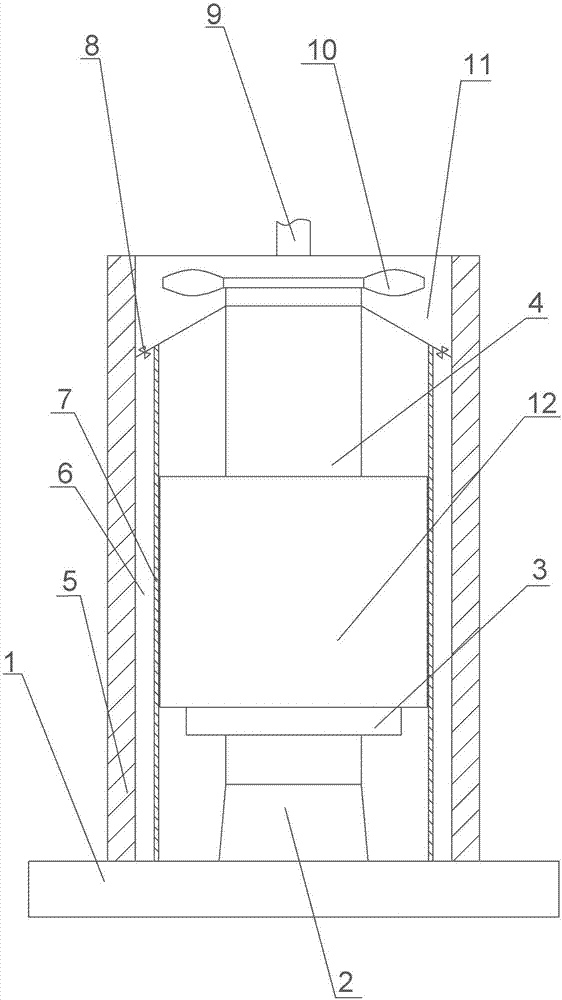

[0014] Embodiment 1 is basically as attached figure 1 Shown: a tooling for the processing of automobile sleeves, including a grinding cylinder 5, a base 1, an air intake pipe 9 and a connector 13 for fixing the automobile sleeve 12, the upper part of the grinding cylinder 5 is an air intake section 11, and the air intake pipe 9 It communicates with the intake section 11. The inner wall of the grinding cylinder 5 is provided with a grinding part, the grinding part includes an air bag 6 and a grinding layer 7, and the grinding layer 7 is arranged on the outer wall of the air bag 6, and the grinding layer 7 is an abrasive belt in this embodiment. The air intake section 11 is in communication with the air bag 6 , and both sides of the air intake section 11 are in a downwardly inclined state to facilitate the flow of gas into the air bag 6 . A one-way valve 8 is provided at the connection between the air intake section 11 and the air bag 6; the base 1 is threadedly connected with ...

Embodiment 2

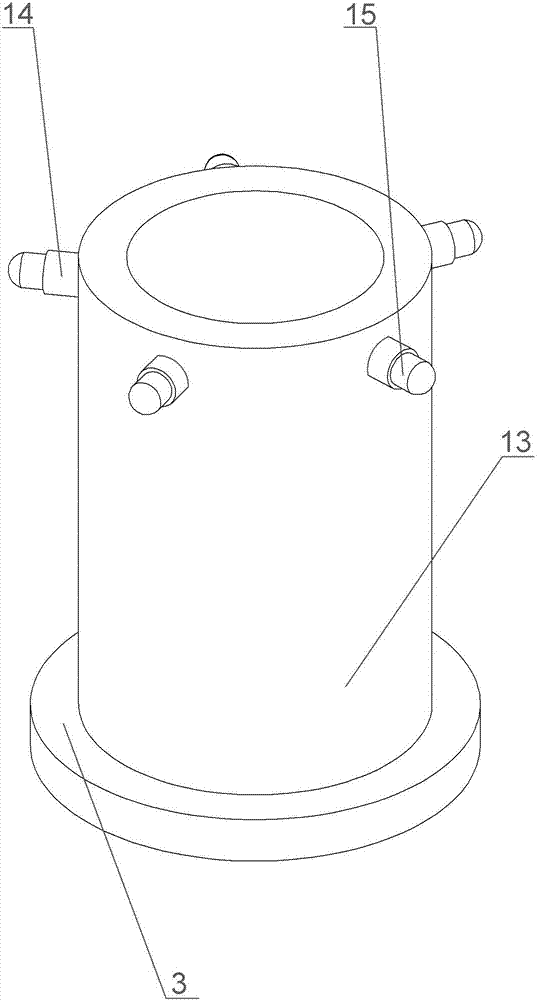

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that it also includes an electromagnet, a storage battery, a remote control switch, a remote controller and a magnetic piece. Remote control switch and remote controller are supporting, all can buy in the market, and its model is B-882 among the present embodiment. The storage battery and the electromagnet are electrically connected through the remote control switch. The electromagnet is located in the first connecting rod 14, and the magnetic part is located in the second connecting rod 15. The electromagnet and the magnetic part attract each other, and the remote control can remotely control the remote control switch. When it is necessary to fix the automobile sleeve 12 with the connecting piece 13, the remote switch is closed by the remote controller, and the electromagnet is energized to generate suction force on the magnetic piece, so that the spring is compressed. At this time, it is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com