Sweet potato flour mill

A technology of mill and sweet potato, applied in the direction of grain processing, etc., can solve the problems of low milling efficiency, affecting the milling effect, adhesion of potato puree, etc., and achieve the effect of improving efficiency and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

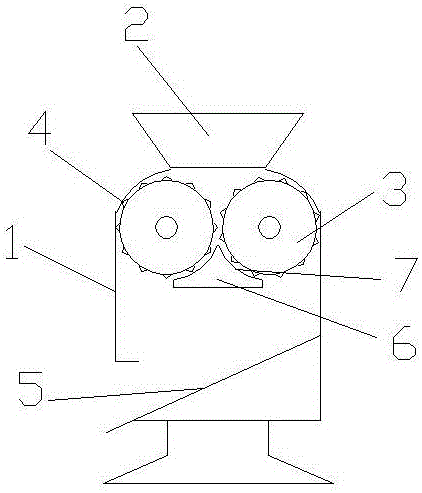

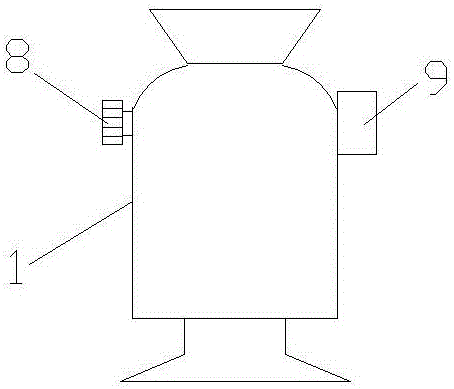

[0013] Combine below figure 1 and figure 2 , to further illustrate the technical solution of the present invention.

[0014] A sweet potato milling machine, comprising a casing 1, the upper end of the casing 1 is connected with a feed inlet 2, and two licker-in rollers 3 are connected side by side and adjacent to each other in the casing 1, and the two licker-in rollers 3 are connected together There is a driving device, and a discharge plate 5 is arranged under the two licker-in rollers 3 .

[0015] There is an auxiliary table 6 next to the adjacent positions of the two licker-in rollers 3, and the auxiliary table 6 is provided with two arc surfaces 7, left and right. The arc surface 7 corresponds to two licker-in rollers 3 respectively, the length of the auxiliary table 6 matches the length of the licker-in roller 3, and the width of the auxiliary table 6 does not exceed the diameter of the licker-in roller 3; below. The curved surface 7 of the auxiliary table 6 and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com