An IC chip burner

A burner and chip technology, applied in semiconductor/solid-state device manufacturing, conveyor objects, electrical components, etc., can solve problems affecting the efficiency of loading and unloading processing, unreasonable loading and unloading structure, simple structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

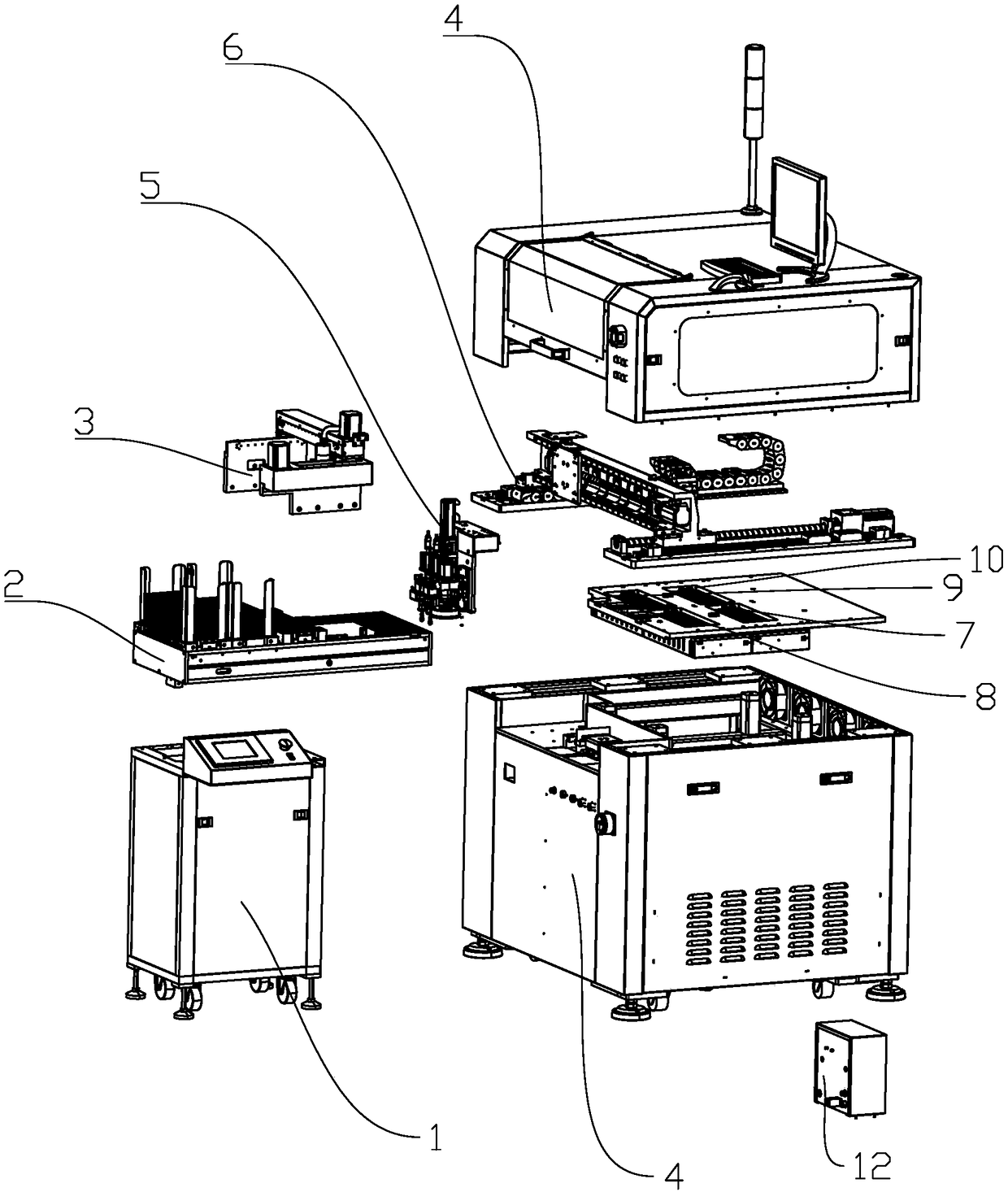

[0035] Combine below Figure 1-Figure 18 The present invention is further described.

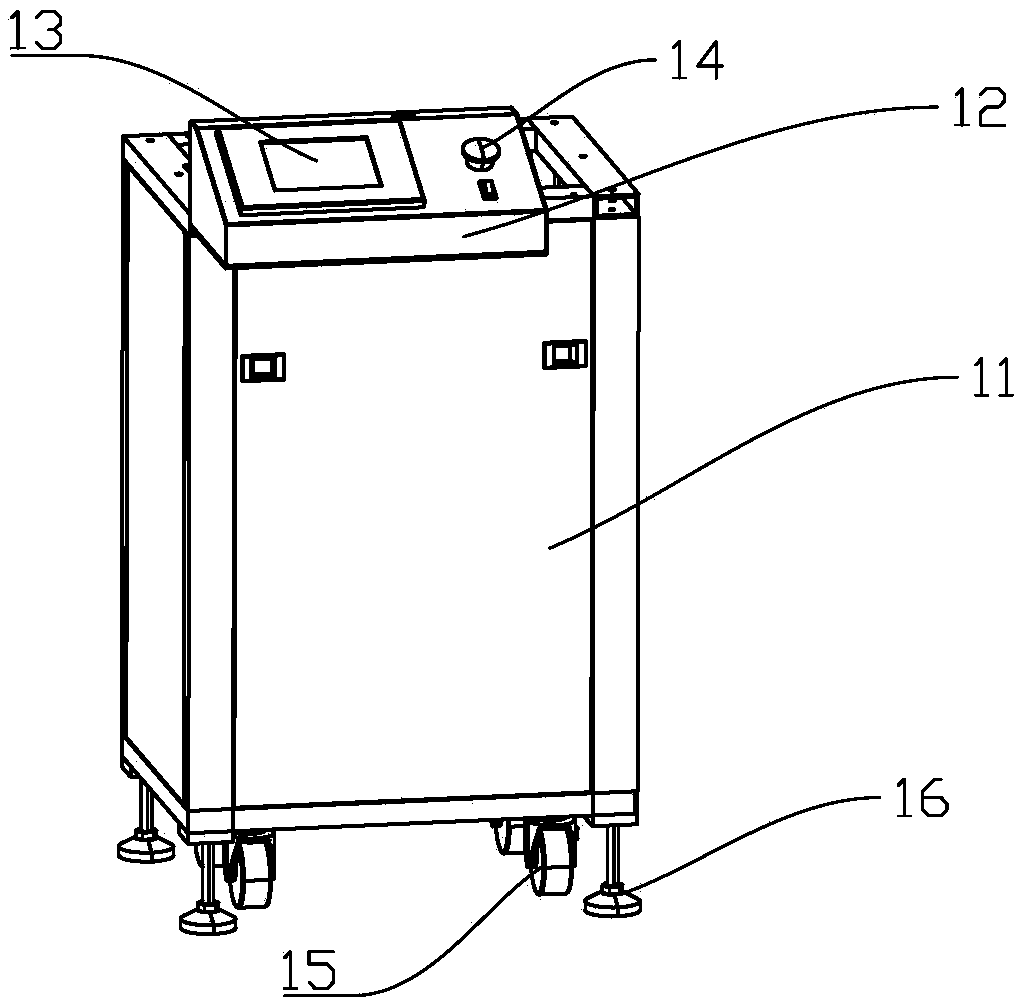

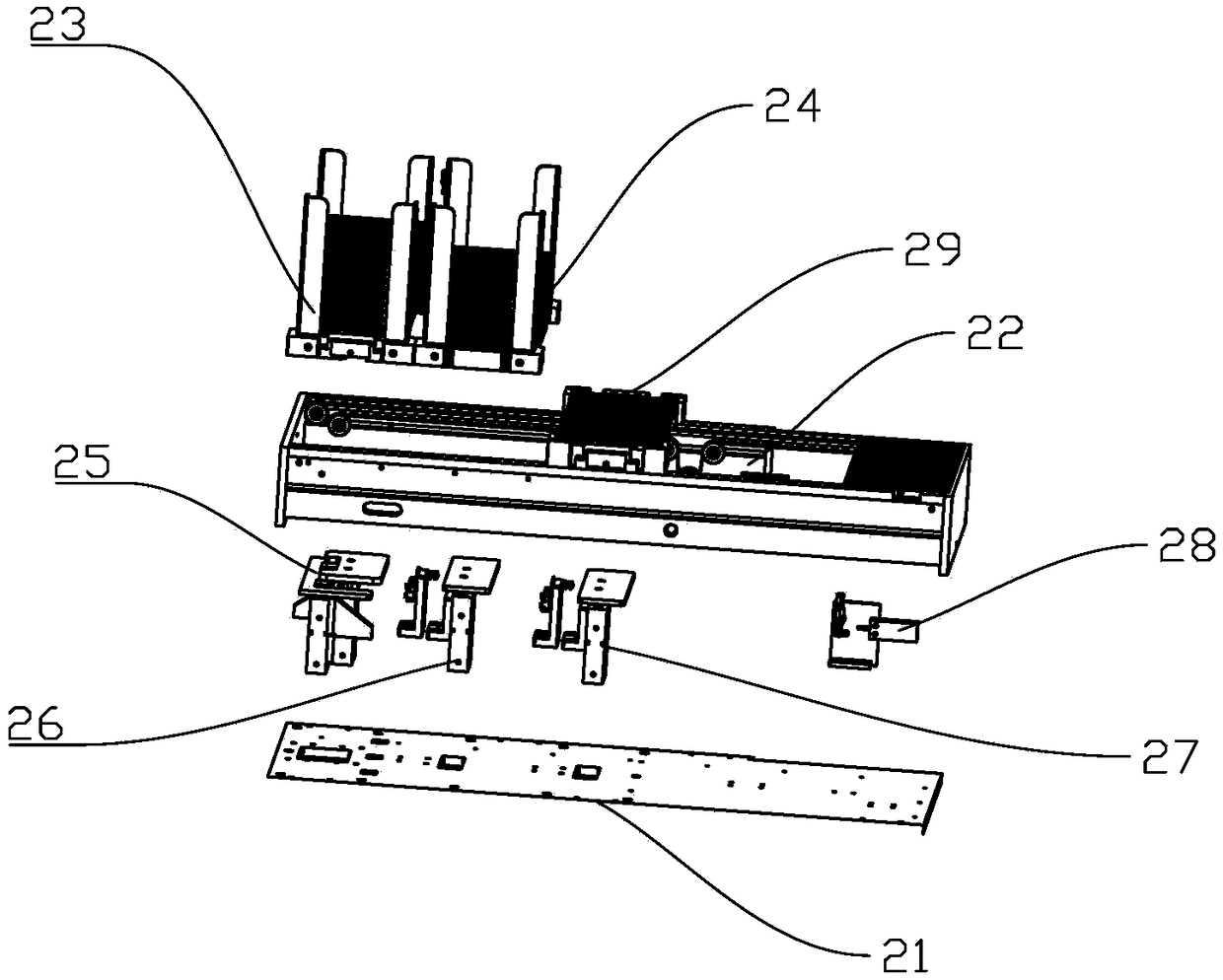

[0036] Such as Figure 1-Figure 18 A kind of IC chip burner shown, comprises feeding frame assembly 1, feeding mechanism 2, code spraying mechanism 3, burning frame assembly 4, manipulator mechanism, burning mechanism and air pressure regulating mechanism 12; The mechanism 2 and the coding mechanism 3 are installed on the loading frame assembly 1 , and the manipulator mechanism, the burning mechanism and the air pressure regulating mechanism 12 are installed on the burning frame assembly 4 .

[0037] Feeding mechanism 2 is used for IC chip loading, IC chip conveying and IC chip unloading; Coding mechanism 3 is located in the middle position of the upper part of feeding mechanism 2, and coding mechanism 3 is used for the IC chip on the feeding mechanism 2 Carry out coding processing; the manipulator mechanism is used for the handling of IC chips between the feeding mechanism 2 and the burni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com