FPC reworking jig and FPC reworking method

A technology of fixture and heating platform, applied in nonlinear optics, instruments, optics, etc., can solve the problems of only discarding, tearing of liquid crystal glass, scrapping of FOG products, etc., to achieve the effect of less time and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

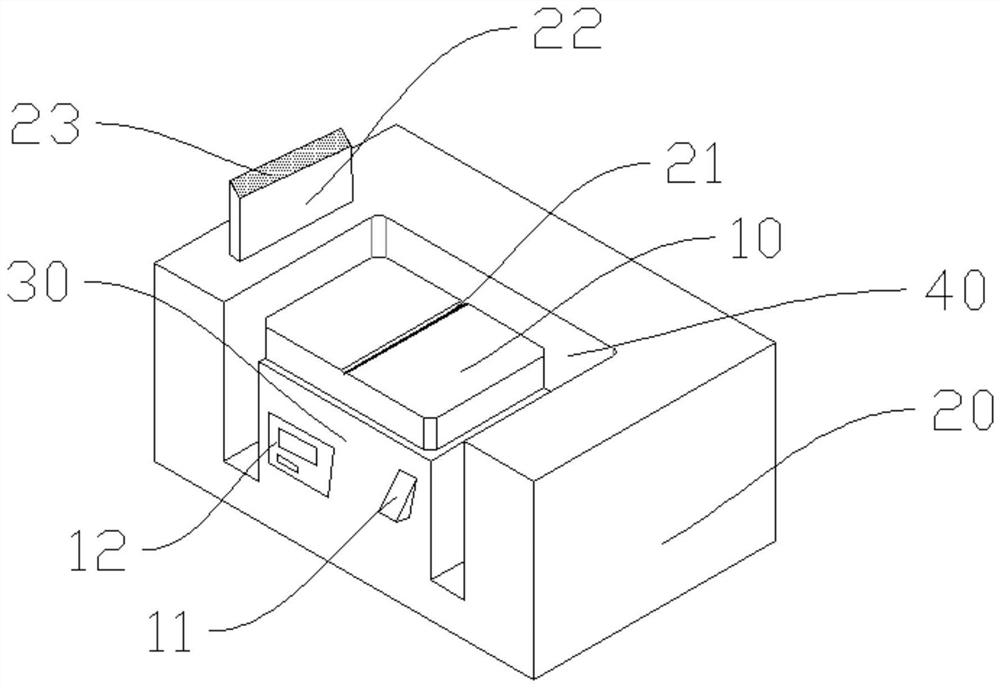

[0034] Such as figure 1 As shown, the present invention is a FPC rework fixture, which comprises: a main frame 20, a heating control circuit (not shown), a heating platform 10 and a support portion 22, and a mounting table 30 is formed on the main frame 20 , the heating platform 10 is arranged on the installation platform 30, the heating control circuit is arranged inside the installation platform 30, and the heating control circuit is electrically connected with the heating platform 10 for controlling the heating Platform 10 operating temperature. The support part 22 is arranged on one side of the main frame 20, the working temperature of the heating platform 10 is 100-200°C, and a positioning part 21 is arranged on the heating platform 10, and the positioning part 21 is connected with the The supporting part 22 cooperates so that when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com