Oil well energy-saving production control system

A technology for production control and oil wells, which is applied in wellbore/well components, measurement, earthwork drilling and production, etc. It can solve the problems of affecting the operation of the control system, increasing production costs, and increasing the error of dynamic fluid level test data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

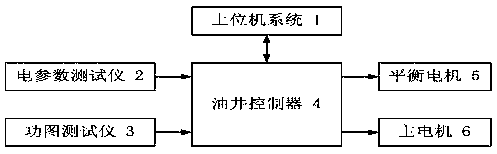

[0024] Example 1: Single well control mode

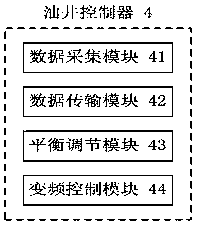

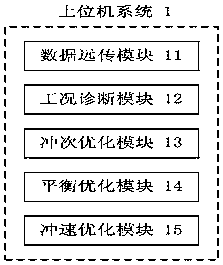

[0025] The electrical parameter tester tests the voltage and current data of the main motor during operation, and the power diagram tester tests the suspension point load and displacement data; the data is transmitted to the data acquisition module inside the oil well controller through wired or wireless transmission. The data is transmitted to the host computer system, and the host computer system performs the following diagnosis and optimization on the oil well working conditions through the analysis of test data:

[0026] Stroke frequency optimization: When it is found that the oil well supply is insufficient, reduce the stroke frequency so that the volumetric efficiency of the oil well pump reaches the set lower limit value. Intermittent pumping system under working conditions; when the volumetric efficiency of the oil well pump exceeds the set upper limit, increase the stroke frequency so that the volumetric efficiency of the o...

Embodiment 2

[0030] Embodiment 2: multi-well control mode ( Figure 4 )

[0031] A set of upper computer system can control the energy-saving production of multiple oil wells at the same time, and its structure is as follows Figure 4 shown. The upper computer system is connected to multiple sets of oil well controllers at the same time, and each set of oil well controllers controls the data acquisition, balance motor and main motor control of one oil well; the upper computer system processes the data acquisition of each oil well controller in sequence according to the set order , Diagnosis and optimization of working conditions, and transmit the optimization results to the corresponding oil well controller at one time.

[0032]The multi-well control method can realize the centralized management of multiple oil wells in one block, save manpower, material resources, resources and reduce production costs.

[0033] The oil well energy-saving production control system in the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com