Energy-saving production method of pentaerythritol

A pentaerythritol, production method technology, applied in chemical instruments and methods, separation/purification of hydroxy compounds, sustainable manufacturing/processing, etc., can solve problems such as side reactions, consumption, pentaerythritol product quality decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

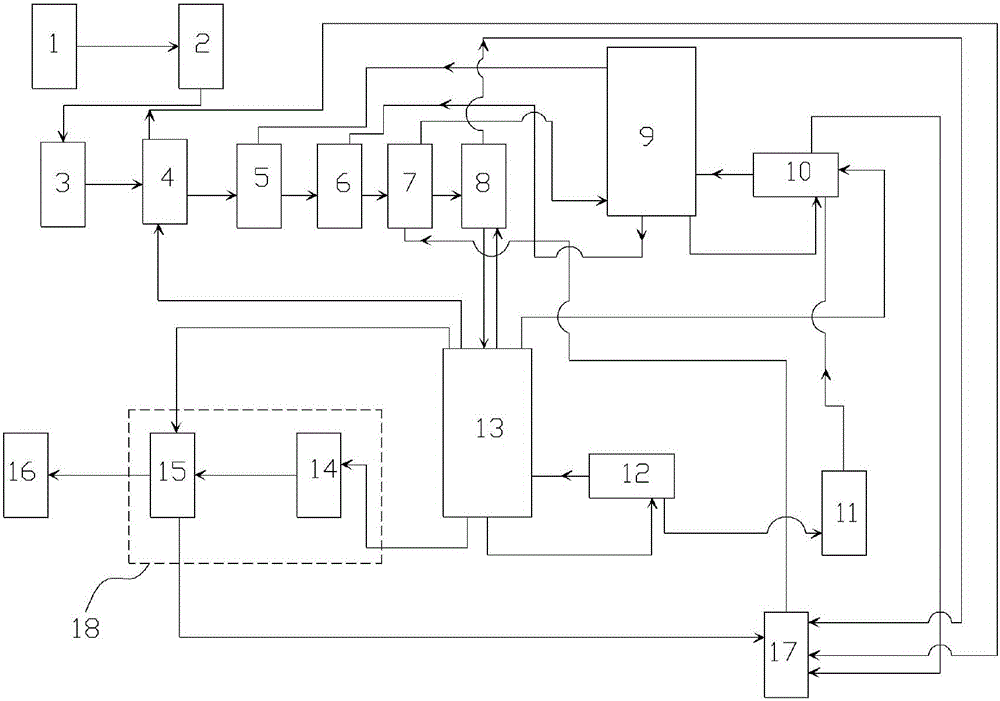

[0036] See figure 1 As shown, a kind of pentaerythritol energy-saving production method provided in this embodiment, the specific structure of the production system that it adopts is: comprise condensation reactor 1, be provided with condensation liquid tank 2, microporous filter 3, Preheating plate cold 4, condensation liquid pre-dealdehyde tower 8, after the condensation liquid pre-dealdehyde tower 8 is provided with a de-aldehyde tower 13, the de-alcohol tower 13 is connected with the de-alcoholization tower 9 through pipelines, after the de-alcoholization tower 13, an evaporation tower 13 is arranged. device 18, a crystallization tank 16 is arranged after the evaporator 18, and the secondary steam outlet of the de-alcoholization tower 13 tower top is respectively connected with the steam inlet of the dealcoholization tower reboiler 10, the steam inlet of the evaporator 18, and condensation through the secondary steam delivery pipeline. The steam inlet of the liquid pre-deald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com