Manufacture system fuzzy control energy saving method based on real-time production data

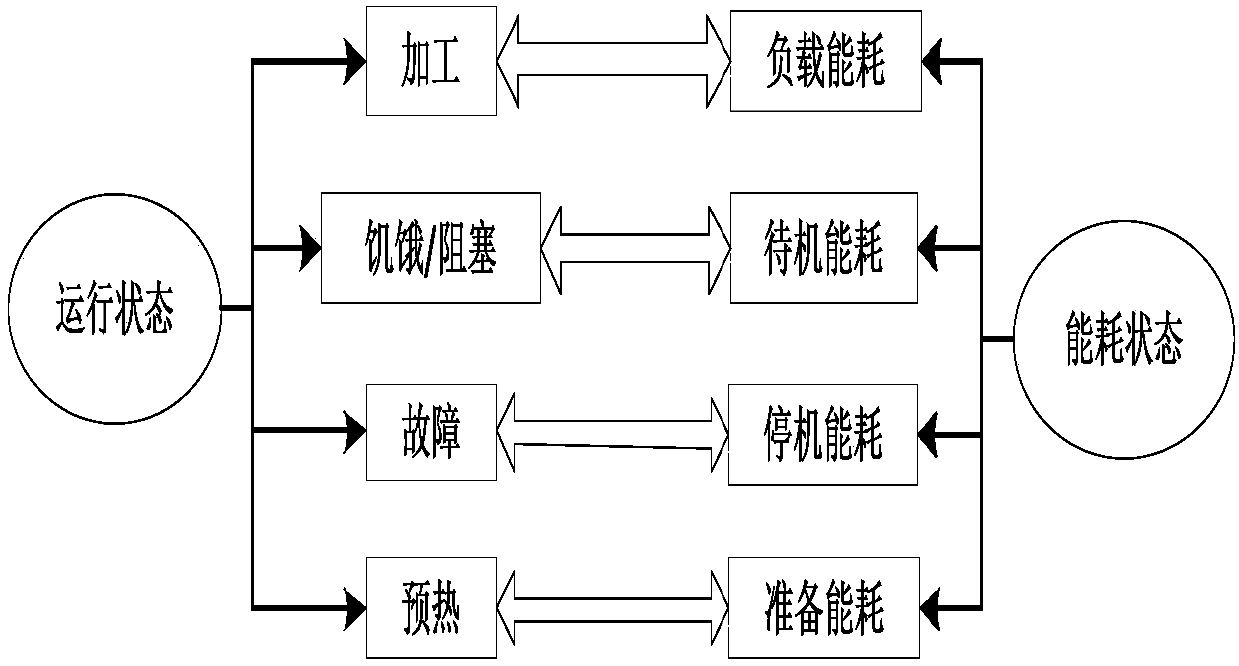

A fuzzy control and manufacturing system technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as difficult system states, missed energy-saving opportunities, accurate descriptions, etc., to achieve low green manufacturing, low energy consumption, The effect of strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

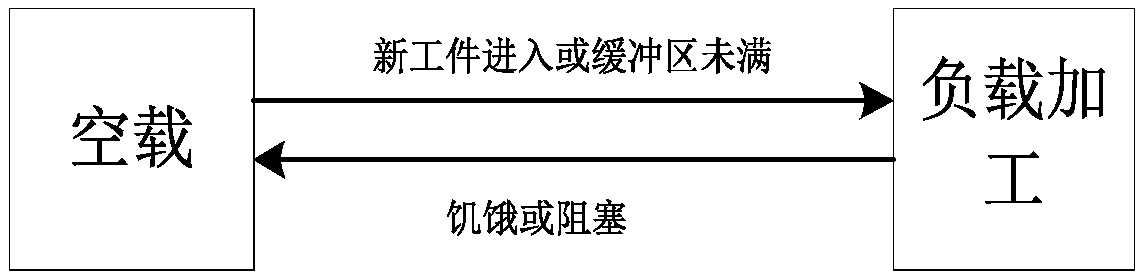

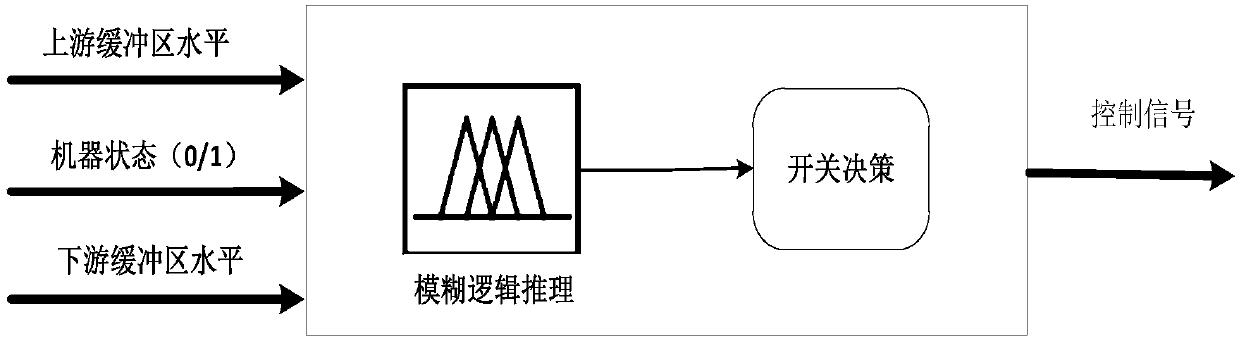

Method used

Image

Examples

example 1

[0070] This example takes the serial unit as an example, where the total capacity of the upstream buffer WIP is 100, and the total capacity of the downstream buffer WIP is 120. The specific steps are as follows:

[0071] (1) Get the current running machine M 3 The WIP quantity in the upstream buffer is 50 and the WIP quantity in the downstream buffer is 25;

[0072](2) Construct the upstream buffer coordinate system and the downstream buffer coordinate system respectively. The maximum value of the X axis of the upstream buffer coordinate system is 100, which is divided into four intervals, the maximum value of the Y axis is 1, and the five area points are respectively Empty area point 0, close to empty area point 25, normal area point 50, close to full area point 75, full area point 100; the maximum value of the X-axis of the downstream buffer coordinate system is 120, which is divided into four intervals, and the maximum value of the Y-axis is 1, and the five area points are...

example 2

[0075] This example takes the serial unit as an example, where the total capacity of the upstream buffer WIP is 200, and the total capacity of the downstream buffer WIP is 200. The specific steps are as follows:

[0076] (1) Get the current running machine M 8 The WIP quantity in the upstream buffer is 190 and the WIP quantity in the downstream buffer is 140;

[0077] (2) Construct the upstream buffer coordinate system and the downstream buffer coordinate system respectively. The maximum value of the X axis of the upstream buffer coordinate system is 200, which is divided into four intervals, the maximum value of the Y axis is 1, and the five area points are respectively Empty area point 0, close to empty area point 50, normal area point 100, close to full area point 150, full area point 200; the maximum value of the X-axis of the downstream buffer coordinate system is 200, which is equally divided into four intervals, and the maximum value of the Y-axis is 1, and the five ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com