Multi-purpose system for high-temperature preheating of hot blast furnace combustion-supporting air

A technology for combustion-supporting air and hot-blast stove, which is applied in hot-blast stove system, hot-blast stove combustion-supporting air high-temperature preheating system, hot-blast stove system renovation or hot-blast stove-system maintenance or renovation alone, and can solve problems such as insufficient capacity of hot-blast stove system , to solve the construction period mismatch, protect the environment, and improve thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

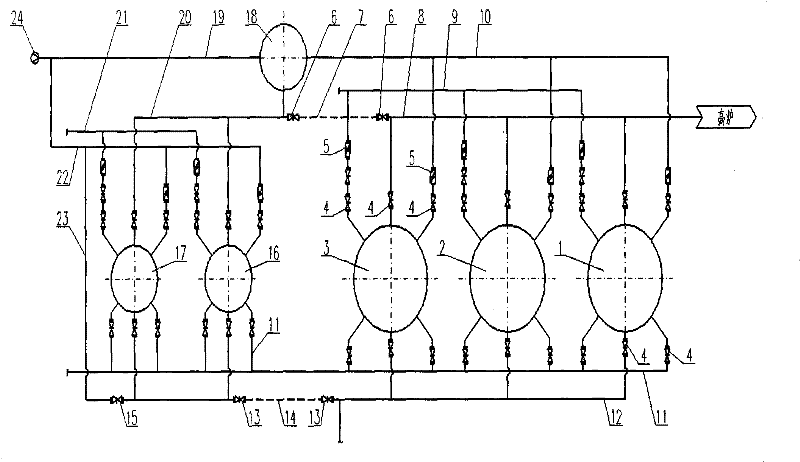

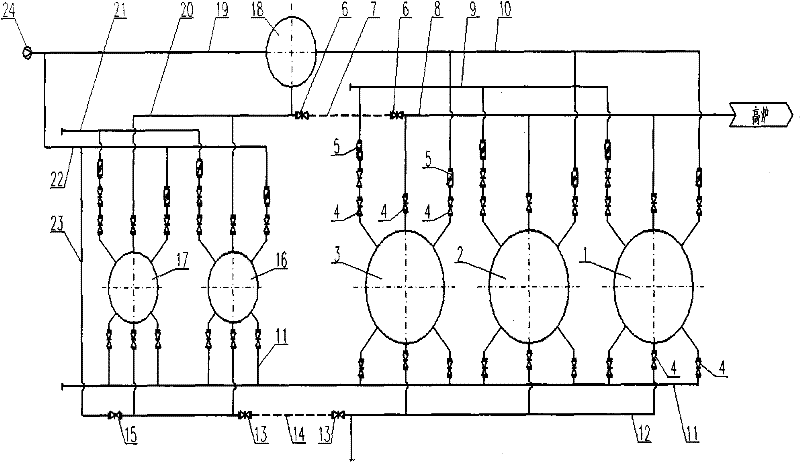

[0039] figure 1 It is a specific implementation of the present invention.

[0040] When the present invention is applied to a blast furnace major renovation project, before the blast furnace and hot blast stove transformation, the preheating furnace and corresponding pipelines shall be constructed first, including the No. 1 preheating furnace 16, the No. 2 preheating furnace 17, the hot air pipe 20, and the preheating Furnace gas pipe 21, preheating furnace air pipe 22, cold air pipe 23, fan 24, and corresponding shut-off valves and regulating valves are installed on each pipeline. In addition, the installation of the temporary hot air valve 6, the temporary hot air pipe 7, the temporary cold air valve 13, and the temporary cold air pipe 14 must be completed.

[0041] The installation and commissioning of the preheating furnace, the corresponding pipes, temporary pipes and temporary valves of the preheating furnace are completed, and the preheating furnace can be officially put in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com