Long-bar rolling production line and production technology thereof

A production process and production line technology, applied in the long product rolling production line and its production process field, can solve the problems of large oxidation and burning loss, consume more electric energy or fuel, and high temperature loss, so as to improve rolling quality and finished product performance, Avoid heat loss and reduce the effect of intermediate processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

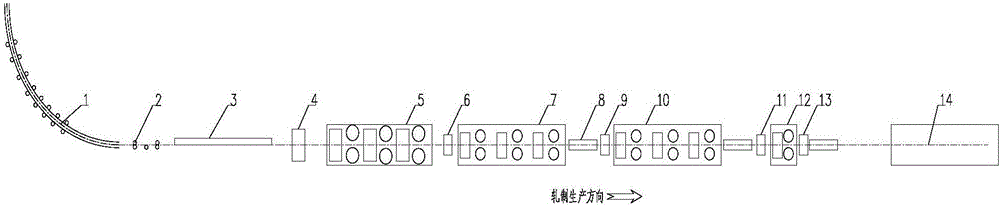

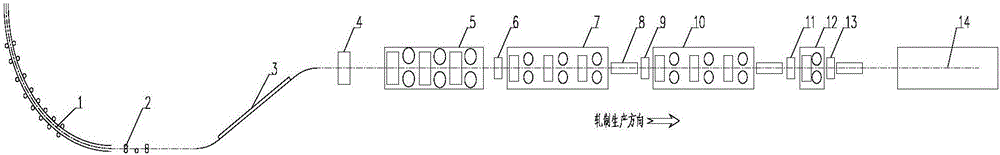

[0038] refer to figure 1 and image 3 , the production process includes single-machine single-strand continuous casting, transport roller table insulation, tension leveler straightening, rough rolling unit rolling, intermediate rolling unit rolling, finishing rolling unit rolling, reducing and sizing unit rolling and cooling collection, continuous The casting line and the rolling line are continuous production lines arranged in parallel. The speed of the continuous production line is based on the pulling speed of the tension leveler. Adjust the speed change to stabilize the speed and ensure the speed accuracy, including the following steps:

[0039] (1) Continuous casting: a single-machine single-strand continuous casting machine is used to produce round billets. The casting speed of the continuous casting machine is 1.5m / min~8m / min, and the cross-sectional diameter of the round billet is Φ120mm~Φ200mm; the follow-up of the continuous casting machine 1 to 5 pairs of floating...

Embodiment 2

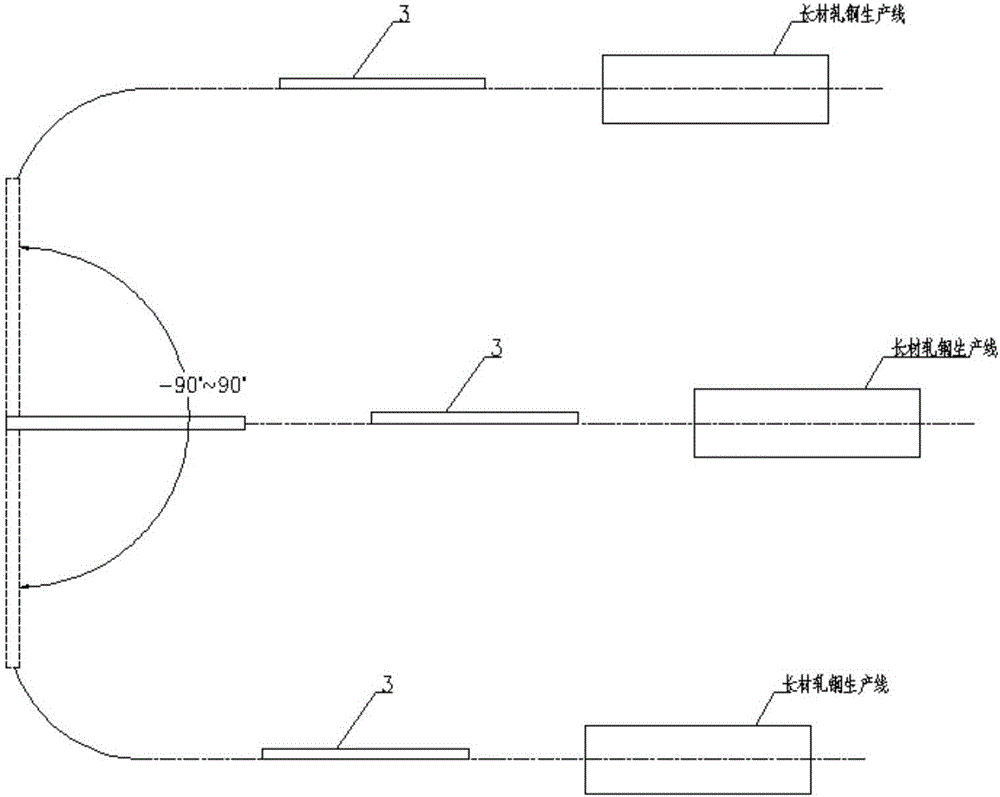

[0046] refer to figure 2 and image 3 , and the difference from Example 1 is that the direction of the billet centerline and the rolling centerline of the continuous casting machine is set at 90°, and the heat preservation roller table is an inclined roller table, which solves the problem that the elevation of the billet centerline is different from the rolling centerline elevation.

Embodiment 3

[0048] refer to figure 1 and image 3 , the difference from Example 1 is that the height of the billet center line from the continuous casting machine is different from that of the rolling center line. The continuous casting machine and the subsequent rolling line are in an "S" shape. All equipment in the rolling line is arranged on an elevated platform, and its rolling centerline is different from the horizontal plane of the rear roller table of the continuous casting machine, which is equivalent to climbing up the slope after the steel is cast from the continuous casting machine, and then rolling. The caster continuous casting and subsequent ramping process is similar to S, so it is called "S" type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com