Preparation method for polysiloxane with extra high molecular weight

A technology of polyorganosiloxane and ultra-high molecular weight, which is applied in the field of preparation of polyorganosiloxane, which can solve the problems of insufficient stirring, limited molecular weight of polyorganosiloxane, and high requirements, so as to avoid partial crosslinking and Uneven heat transfer, reducing the effect of intermediate processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

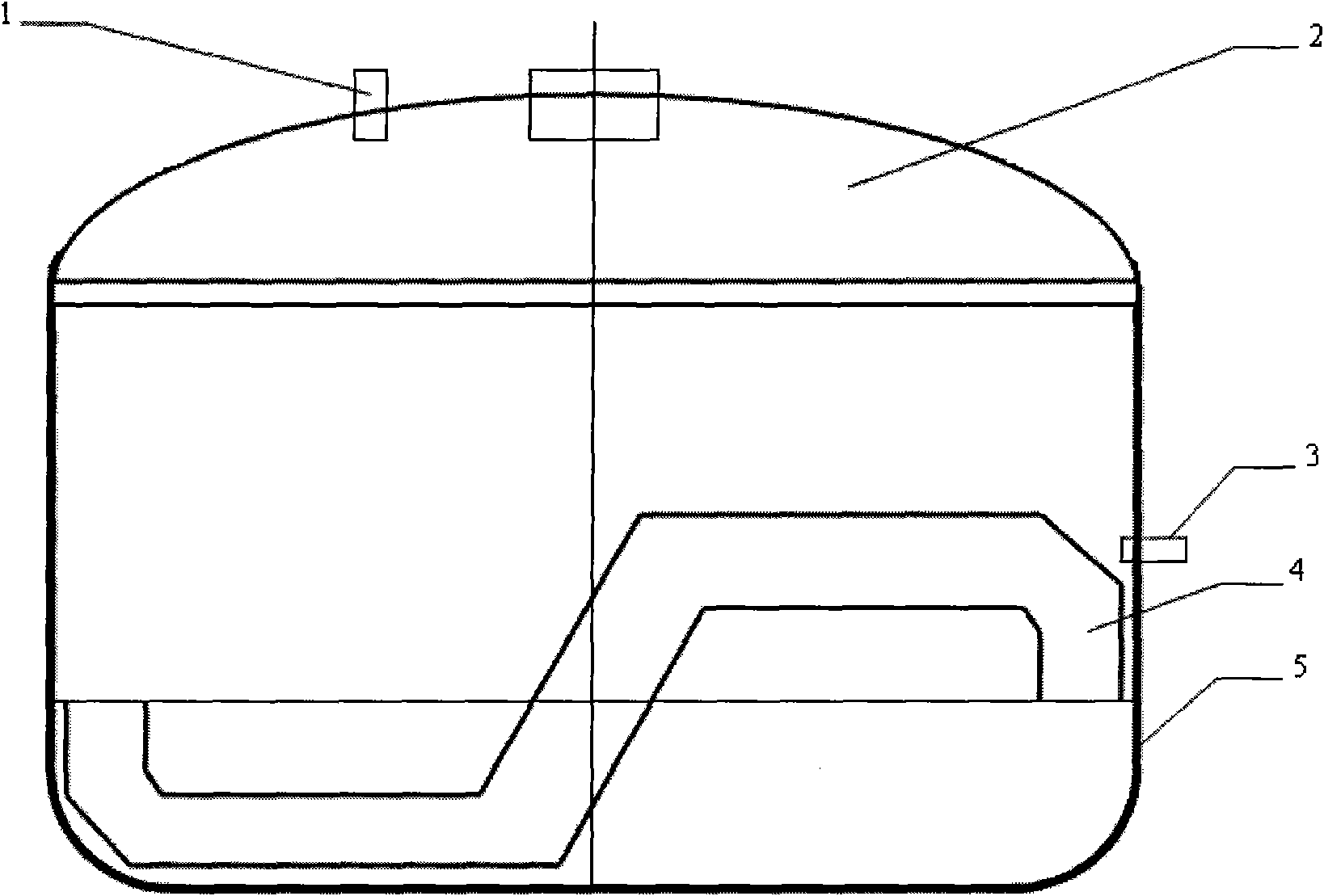

[0030] Add 18kg of dimethylcyclosiloxane into a 40L reactor, start the agitator, control the speed at 30 rpm, raise the temperature to 130°C, add 0.18g of potassium siloxanate at constant temperature to catalyze the reaction for 6.0 hours; Then, vacuumize for 4.0 hours, and control the vacuum degree to -0.080MPa; then neutralize with 0.18g of silicon-based phosphate, and raise the temperature to 170°C, pass in nitrogen and continue vacuuming for 6.0 hours; stop heating, stir and cool to room temperature, and then exit material, you can prepare ultra-high molecular weight polydimethylsiloxane.

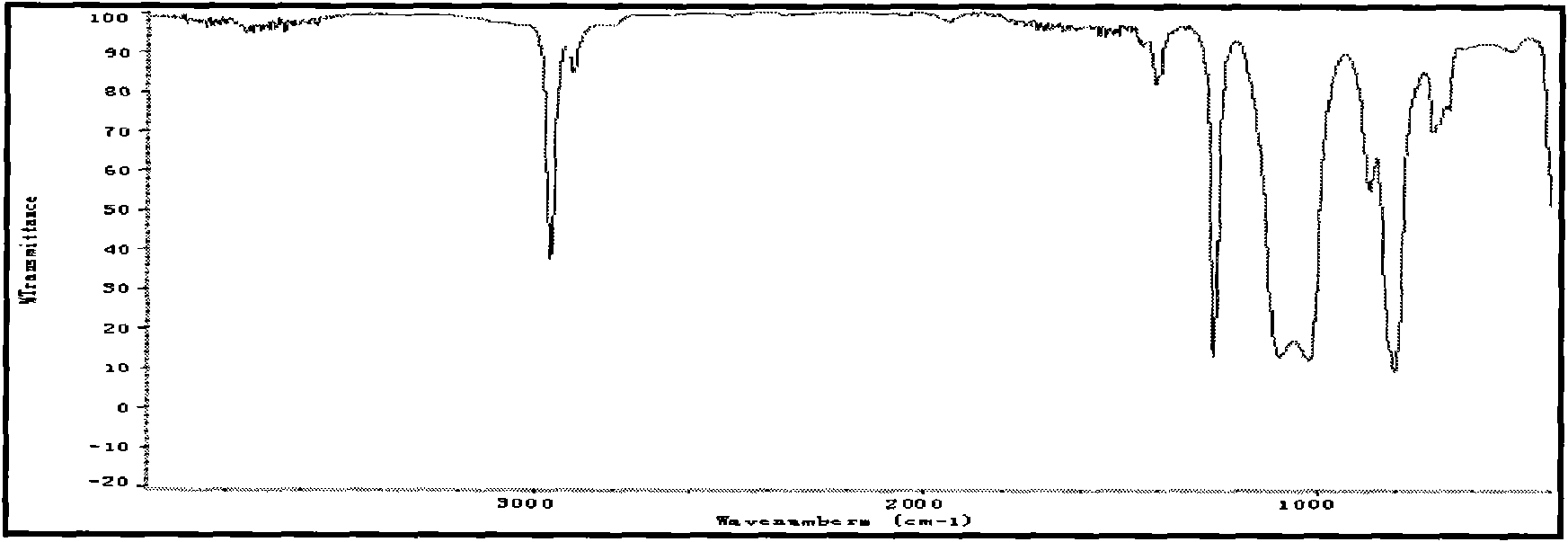

[0031] Extract above-mentioned polydimethylsiloxane product, adopt Fourier transform infrared spectrometer to test, from figure 2 Visible, in the infrared spectral map 1020cm -1 -1090cm -1 There is an obvious characteristic absorption peak of polydimethylsiloxane.

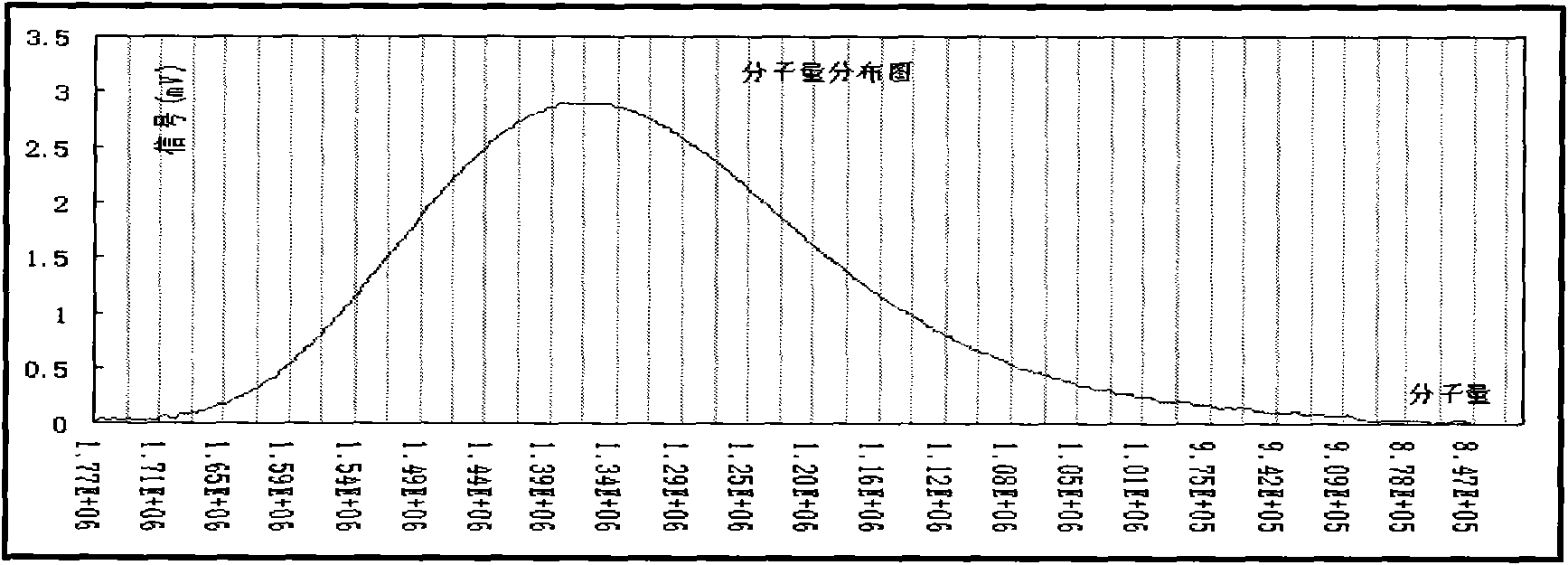

[0032] Extract ultra-high molecular weight polydimethylsiloxane, adopt Waters 515 gel permeation chromatography system...

Embodiment 2

[0034] Add 18kg of α,ω-dihydroxypolydimethylsiloxane into a 40L reactor, start the stirrer, control the speed at 40 rpm, raise the temperature to 140°C, and add 1.8g of sodium siloxane alkoxide at constant temperature to catalyze React for 5.0 hours; under constant temperature, vacuumize for 3.0 hours, and control the vacuum degree to -0.080MPa; then neutralize with 2.5g phosphoric acid, and raise the temperature to 180°C, feed nitrogen and continue vacuuming for 5.0 hours; stop heating, stir and cool to After discharging at room temperature, ultra-high molecular weight polydimethylsiloxane can be prepared.

Embodiment 3

[0036] Add 18kg of dimethylcyclosiloxane into a 40L reactor, start the agitator, control the speed at 50 rpm, raise the temperature to 150°C, and add 5.0g of cesium siloxanolate at constant temperature to catalyze the reaction for 3.0 hours; at constant temperature Then, vacuumize for 2.0 hours, and control the vacuum degree to -0.090MPa; then use 3.2g of acetic acid to neutralize, and raise the temperature to 170°C, feed nitrogen and continue vacuuming for 4.0 hours; stop heating, stir and cool to room temperature, and discharge, that is Ultra-high molecular weight polydimethylsiloxane can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com