Automatic blanking and ring cutting process

A process and ejection technology, which is applied in the field of automatic production blanking and round cutting process, can solve the problems of time-consuming and labor-intensive manual cutting, uneven shearing section, high cost of stamping die, etc., to achieve firm equipment, reduce intermediate processes, and less material waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

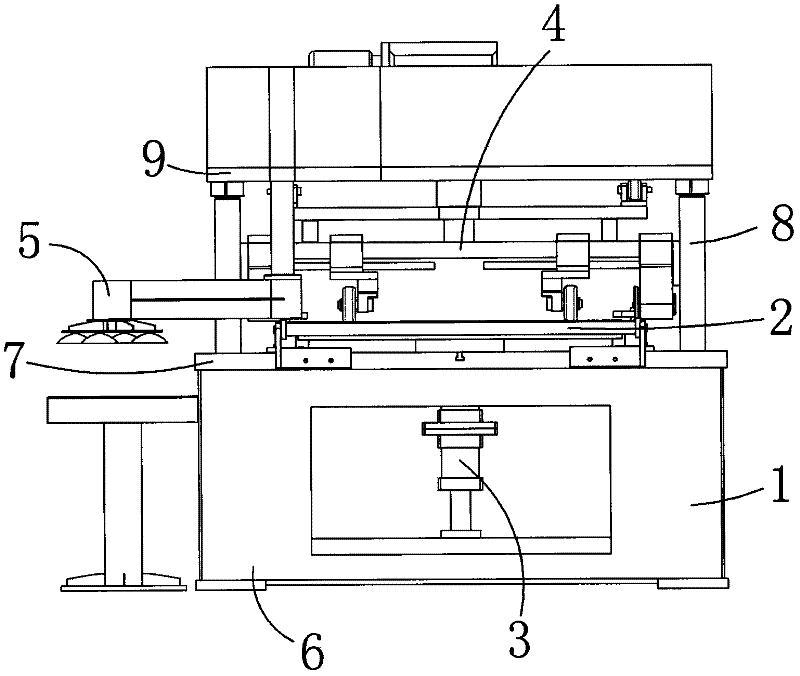

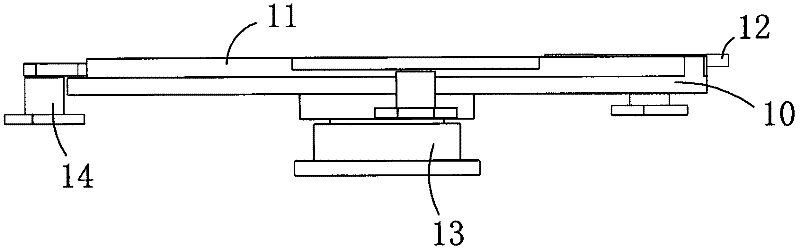

[0029] Examples, see attached Figure 1-5 , an automatic production blanking and cutting circle process, comprising the following steps:

[0030] a) Blanking: Obtain a strip-shaped or roll-shaped blank, and transport the resulting blank to the mold device 2;

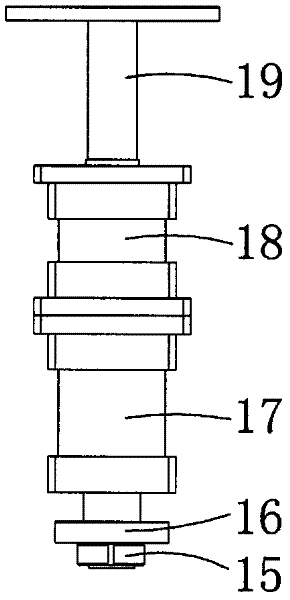

[0031] b) Positioning and pressing: under the action of the hydraulic piston, the crossbeam on the fuselage assembly 1 is lowered, so that the pressing knife on the shearing device 4 presses the blank for positioning and pressing;

[0032] c) Shearing and forming: when the shearing work starts, two or four sets of shearing knives start to shear from both sides of the blank, and the knife holder on the shearing device can cut out a circle or ring every half rotation workpiece;

[0033] d) Reset of the shearing device: After the tool holder completes the rotary movement, under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com