Method for refining hypo eutectic aluminum-silicon alloy structure

A technology for refining hypoeutectic and aluminum-silicon alloys, applied in the field of refining aluminum-silicon alloys, can solve the problems of affecting the purity and performance of the alloy, affecting the microstructure and performance of materials, production and social environmental pollution, and eliminating the heat treatment process. , easy to operate, and quick to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

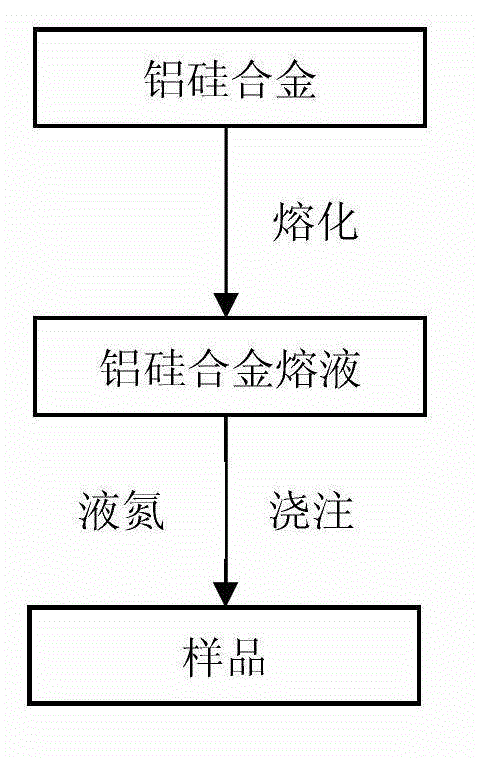

[0016] Such as figure 1 As shown, the operation steps for refining the Al-Si alloy structure are:

[0017] (1) Put the aluminum-silicon alloy billet into a box-type resistance furnace and heat it to 720 degrees to melt the billet;

[0018] (2) Keep warm for 10 minutes to make the melt structure uniform;

[0019] (3) Take it out of the box, and quickly pour the aluminum-silicon alloy melt in a liquid nitrogen environment to rapidly cool the aluminum-silicon alloy and solidify it into shape.

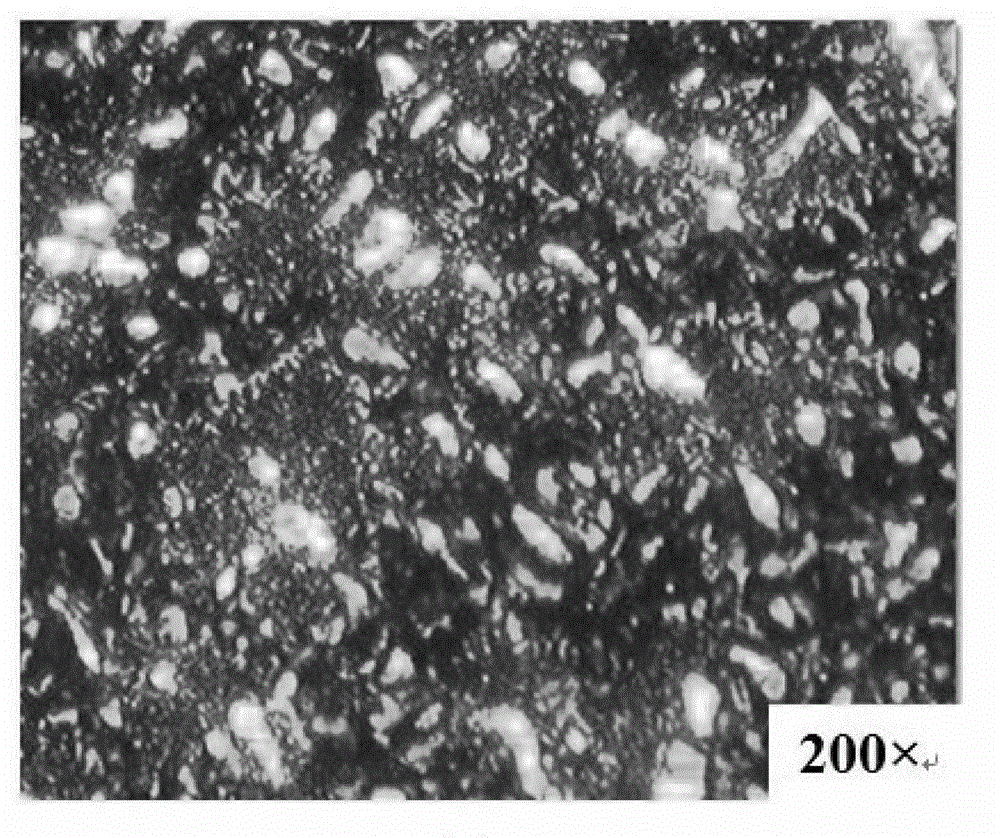

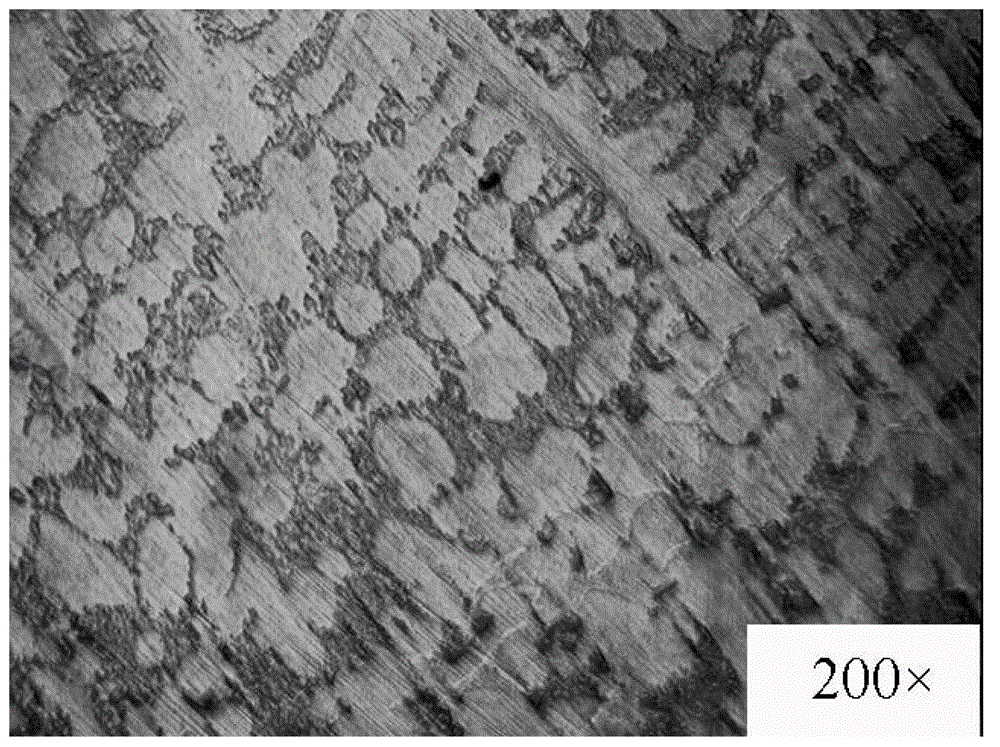

[0020] The sample is made into a metallographic sample, and the microstructure is observed with an OLYMPUSBX51 metallographic microscope, and the obtained metallographic diagram (such as figure 2 ), it can be seen that there are many eutectic structures, and they are evenly distributed. The size is about 3μm-15μm. image 3 In order to compare the metallographic diagram of the sample, it can be seen that the eutectic structure of the sample is very coarse.

Embodiment 2

[0022] Such as figure 1 As shown, the operation steps for refining the Al-Si alloy structure are:

[0023] (1) Put the billet of AC4B aluminum-silicon alloy into a box-type resistance furnace and heat it to 670 degrees to melt the billet;

[0024] (2) Keep warm for 15 minutes to make the melt structure uniform;

[0025] (3) Take it out of the box, and quickly pour the aluminum-silicon alloy melt in a liquid nitrogen environment to rapidly cool the aluminum-silicon alloy and solidify it into shape.

Embodiment 3

[0027] Such as figure 1 As shown, the operation steps for refining the Al-Si alloy structure are:

[0028] (1) Put the aluminum-silicon alloy billet into a box-type resistance furnace and heat it to 700 degrees to melt the billet;

[0029] (2) Keep warm for 20 minutes to make the melt structure uniform;

[0030] (3) Lower the temperature of the furnace to the temperature of the two-phase zone, such as 630 degrees, and keep it warm for 10 minutes;

[0031] (4) Take it out of the box, and quickly pour the aluminum-silicon alloy melt in a liquid nitrogen environment to rapidly cool the aluminum-silicon alloy and solidify it into shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com