Early warning method for rotating stall of axial-flow air compressor based on frequency domain hump identification

An axial flow compressor, rotating stall technology, applied in character and pattern recognition, pattern recognition in signals, mechanical equipment, etc., can solve the problem that the stability active control technology is difficult to practical application of aero-engine, and the actuation system is difficult, etc. problems, to achieve the effect of fast calculation speed, sufficient response time, and few intermediate processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

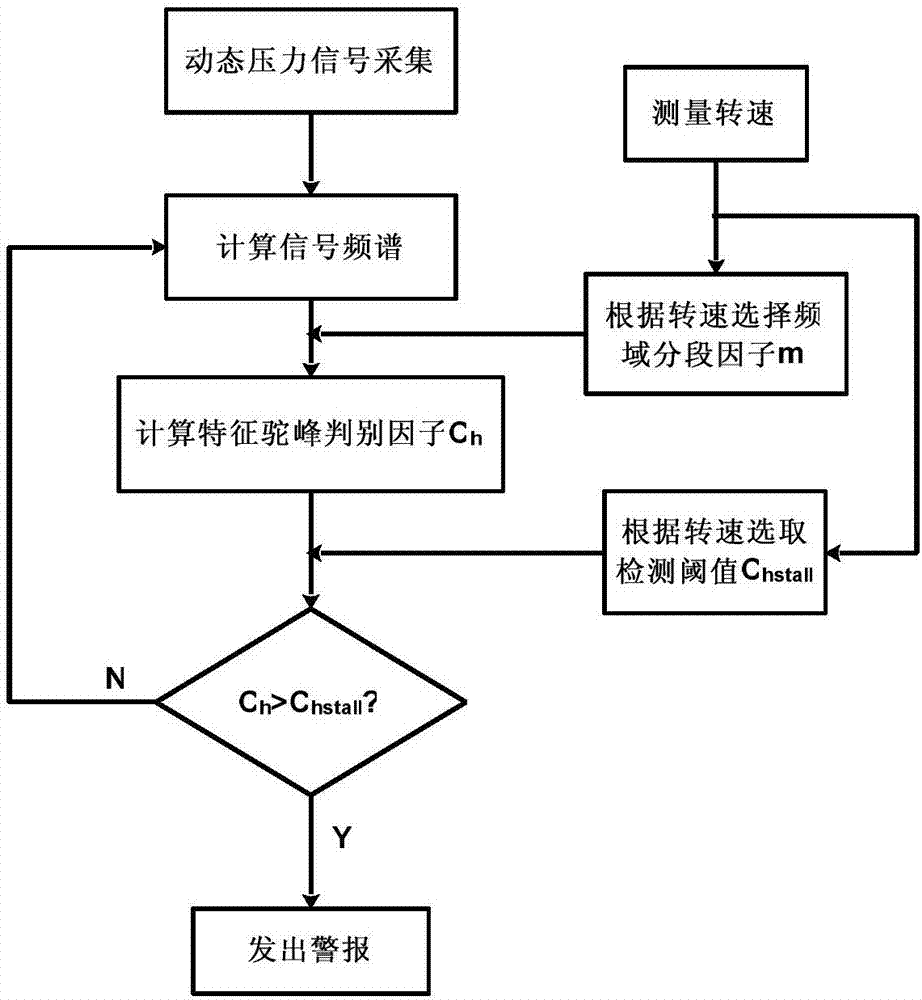

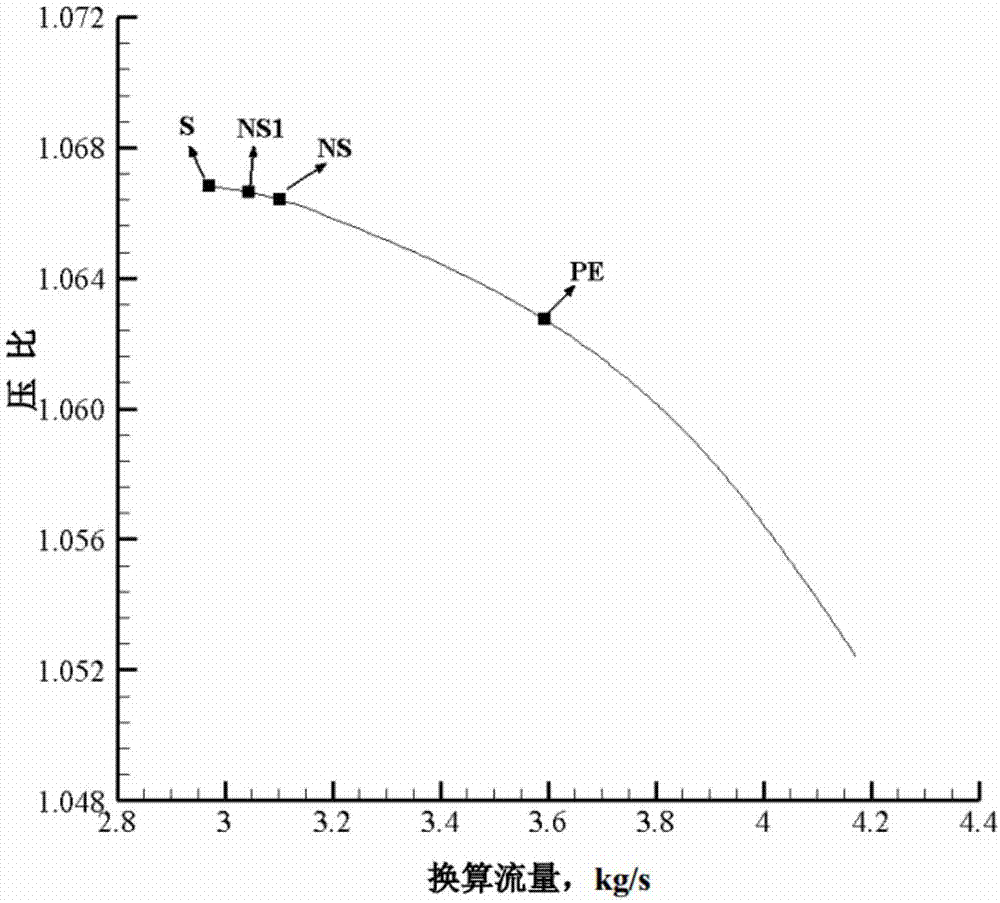

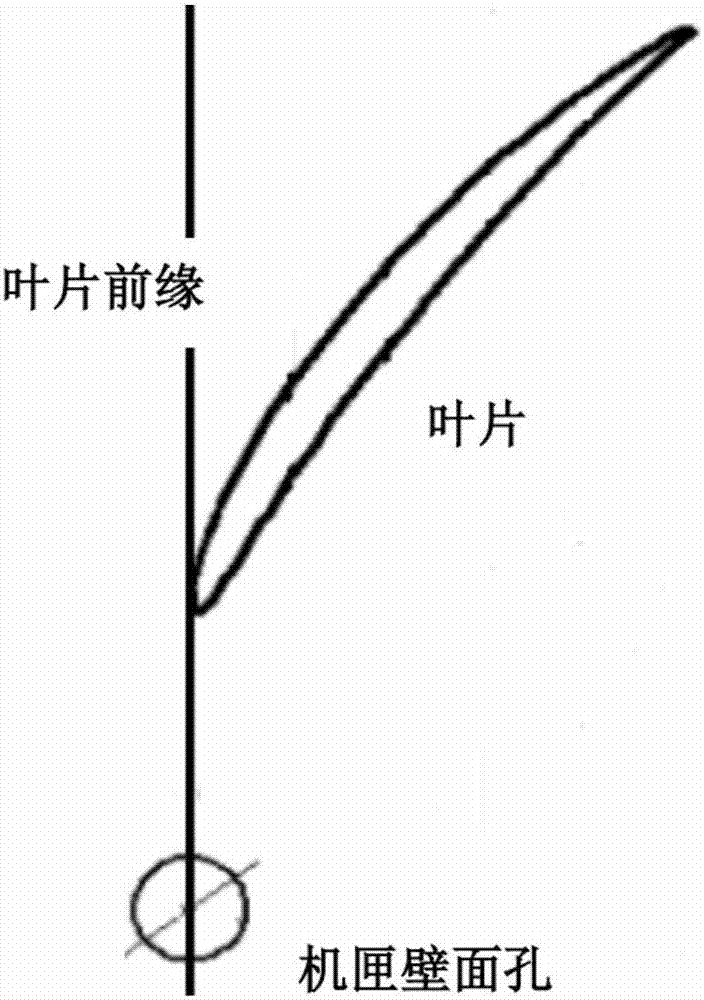

[0028] This embodiment is a method for early warning of rotating stall of an axial flow compressor based on frequency domain hump recognition. This method continuously collects dynamic pressure signals, uses fast Fourier transform to continuously calculate the frequency spectrum of the pressure signal within a compressor rotation cycle, and calculates the characteristic hump discriminant factor C corresponding to the frequency spectrum h , by humping the feature discriminant factor C h with detection threshold C hstall By comparison, it is judged whether the compressor is close to the rotating stall boundary. Axial flow compressor rotating stall early warning method only needs a single signal sensor; characteristic hump discriminant factor C h It has a clear physical meaning, since the hump in the frequency domain appears before the stall precursor, by identifying the hump in the frequency domain, sufficient response time is provided for the active control, and the real-time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com