Electrolytic aluminium system adopting non-grid multi-energy collaborative power supply

An electrolytic aluminum and multi-energy technology, applied in the field of electrolytic aluminum, can solve the problems of power fluctuations in the power grid, high process requirements, and high construction costs, and achieve the effects of reducing intermediate processes, increasing economic benefits, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

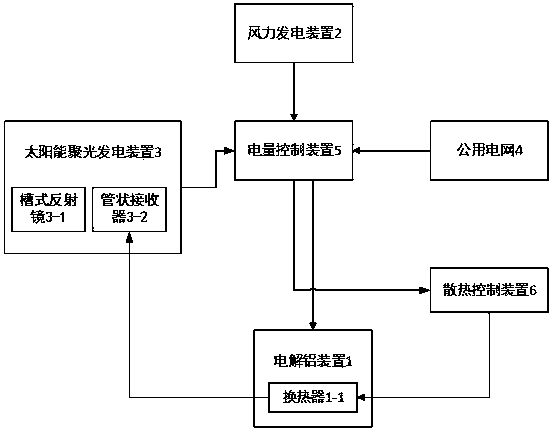

[0022] The non-grid-connected electrolytic aluminum system of multi-energy cooperative power supply in this embodiment, such as figure 1 As shown, it includes an electrolytic aluminum device 1, a solar concentrating power generation device 3 and a wind power generation device 2. The solar concentrating power generation device 3 includes a trough reflector 3-1 and a tubular receiver 3-2. The aluminum electrolysis of the electrolytic aluminum device 1 The side wall casing of the tank is provided with a heat exchanger 1-1 equipped with a heat-conducting medium.

[0023] This embodiment also includes a power control device 5 for coordinated control of the power supplied to the electrolytic aluminum device 1 and a heat dissipation control device 6 for controlling the flow rate of the heat transfer medium in the heat exchanger 1-1; The insulation layer wraps the heat exchanger 1-1 on the side wall shell of the aluminum electrolytic cell, and the heat exchanger 1-1 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com