Crushing and screening equipment for automobile tire recycling

A technology for screening equipment and automobile tires, applied in recycling technology, plastic recycling, mechanical material recycling, etc., can solve problems such as uncontrollable feeding rate and inconvenient screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

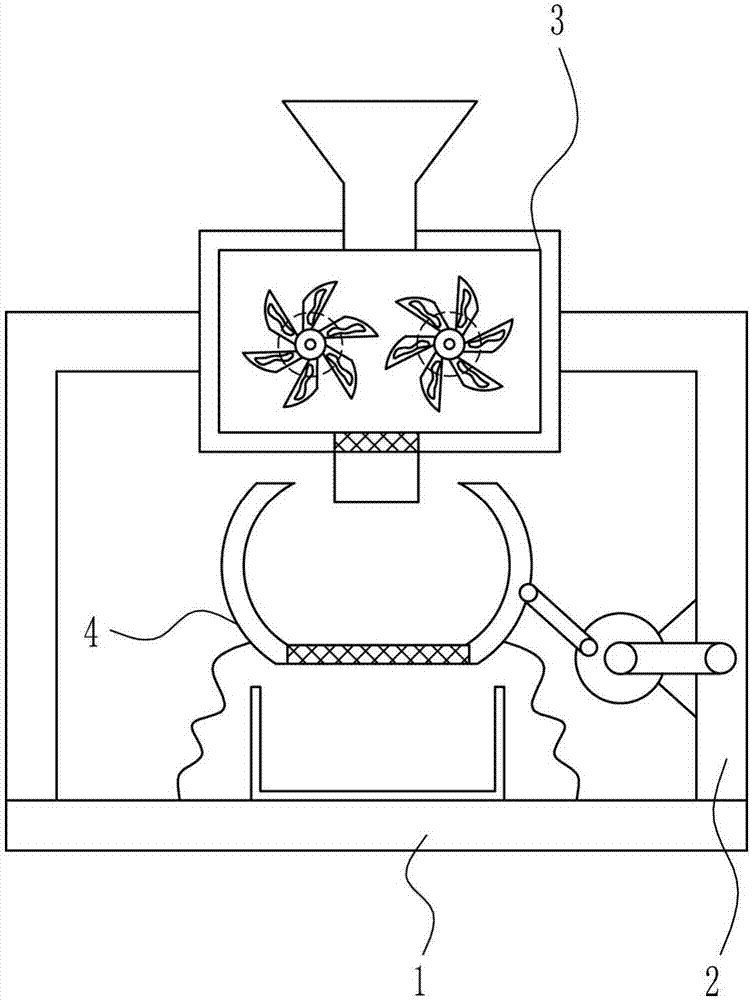

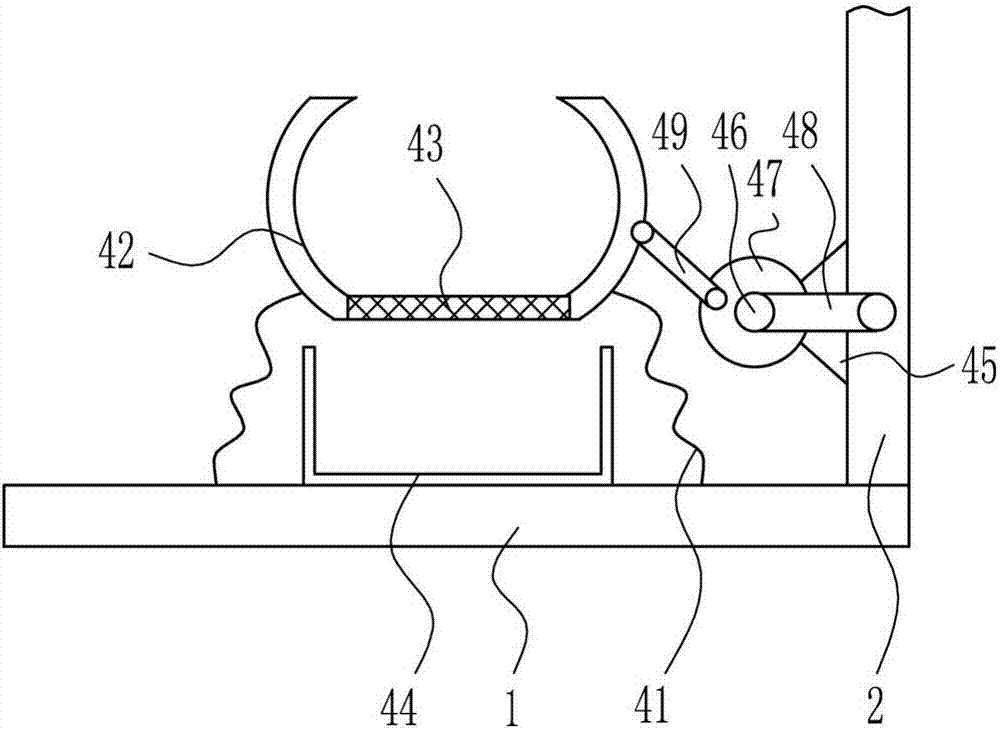

[0029] A crushing and screening equipment for recycling automobile tires, such as Figure 1-5 As shown, it includes a bottom plate 1, an L-shaped support 2, a crushing device 3 and a screening device 4. The top of the bottom plate 1 is symmetrically provided with an L-shaped support 2, and a crushing device 3 is provided between the two L-shaped supports 2. The crushing device 3 Below is provided with screening device 4.

Embodiment 2

[0031] A crushing and screening equipment for recycling automobile tires, such as Figure 1-5 As shown, it includes a bottom plate 1, an L-shaped support 2, a crushing device 3 and a screening device 4. The top of the bottom plate 1 is symmetrically provided with an L-shaped support 2, and a crushing device 3 is provided between the two L-shaped supports 2. The crushing device 3 Below is provided with screening device 4.

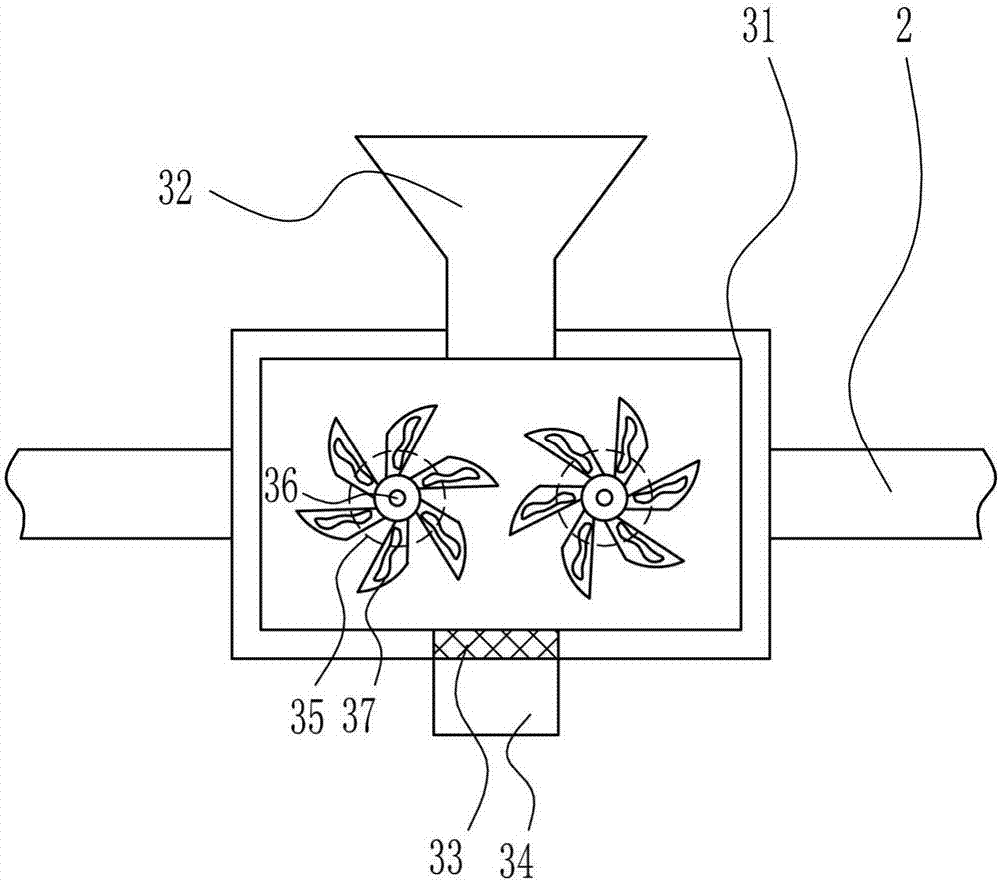

[0032] The crushing device 3 includes a crushing frame 31, a feed hopper 32, a first filter screen 33, a discharge pipe 34, a motor 35, a first rotating shaft 36 and a crushing blade 37, and a crushing frame 31 is arranged between the two L-shaped supports 2. , the top center of the crushing frame 31 is provided with a hopper 32, the center of the bottom of the crushing frame 31 is provided with a first filter screen 33, the bottom below the first filter screen 33 is provided with a discharge pipe 34, and the rear wall of the crushing frame 31 is symmetrical...

Embodiment 3

[0034] A crushing and screening equipment for recycling automobile tires, such as Figure 1-5 As shown, it includes a bottom plate 1, an L-shaped support 2, a crushing device 3 and a screening device 4. The top of the bottom plate 1 is symmetrically provided with an L-shaped support 2, and a crushing device 3 is provided between the two L-shaped supports 2. The crushing device 3 Below is provided with screening device 4.

[0035] The crushing device 3 includes a crushing frame 31, a feed hopper 32, a first filter screen 33, a discharge pipe 34, a motor 35, a first rotating shaft 36 and a crushing blade 37, and a crushing frame 31 is arranged between the two L-shaped supports 2. , the top center of the crushing frame 31 is provided with a hopper 32, the center of the bottom of the crushing frame 31 is provided with a first filter screen 33, the bottom below the first filter screen 33 is provided with a discharge pipe 34, and the rear wall of the crushing frame 31 is symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com