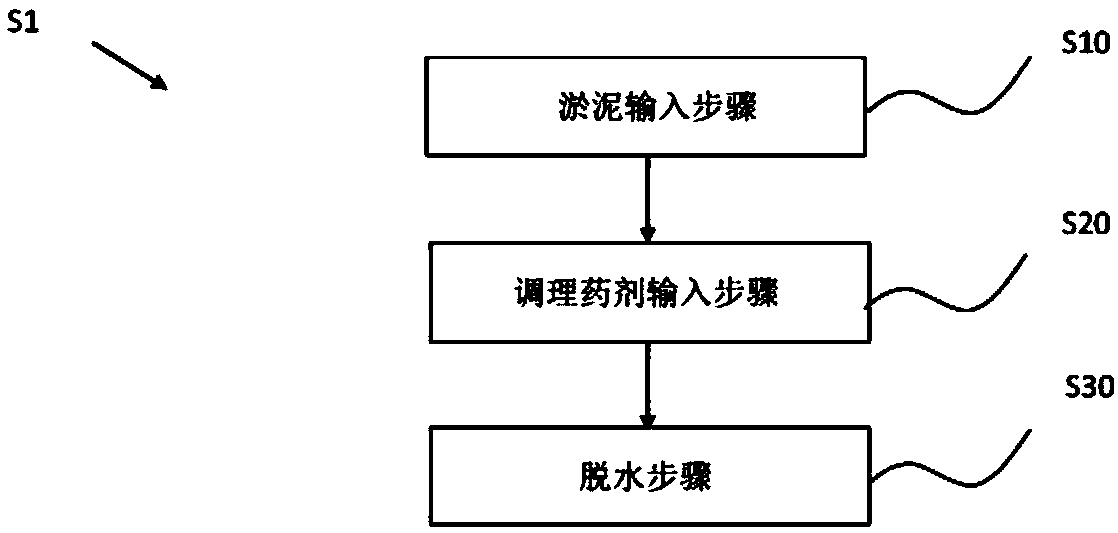

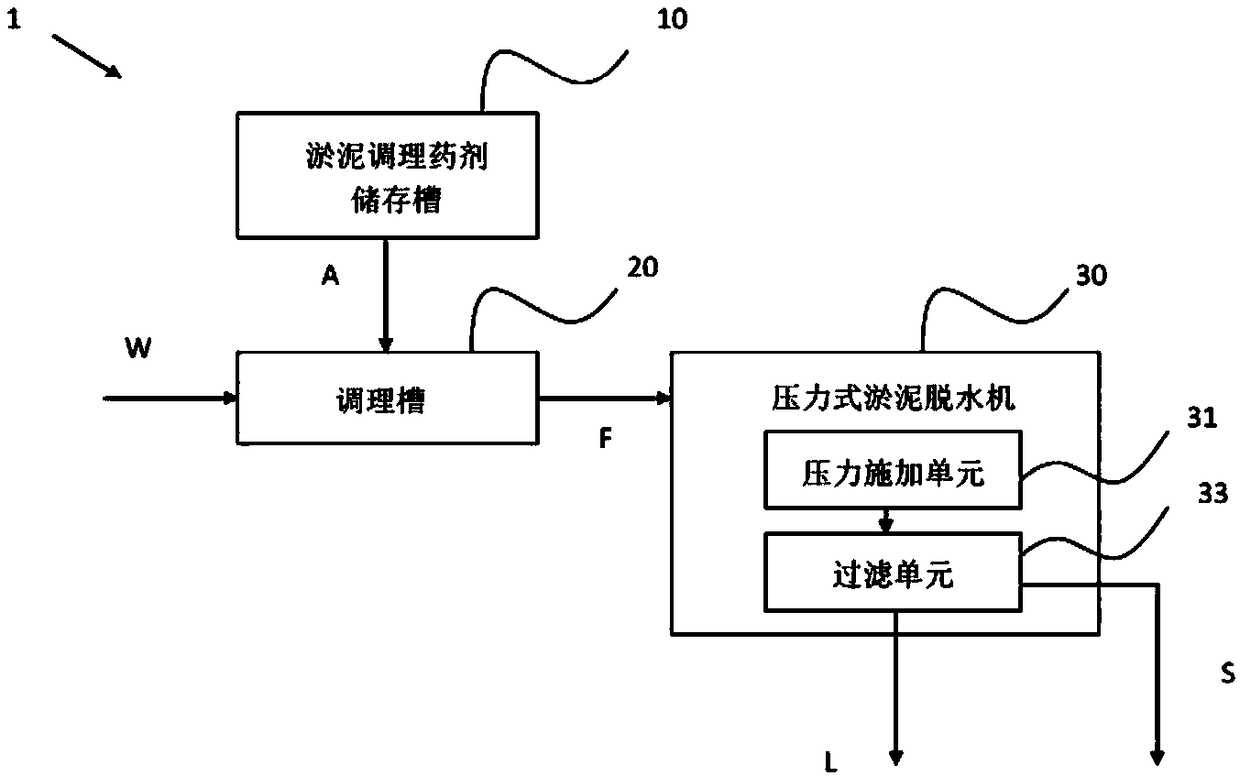

Organic sludge conditioning agent and method for using agent to dewater sludge

A technology of organic sludge and chemicals, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problem of easy blockage of pipelines and the inability to effectively reduce the cost of cleaning and transportation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Here, an organic sludge conditioning agent is provided. The organic sludge conditioning agents include alkyl amine salt compounds, polyamine polymers, and iron-based inorganic salts. The alkyl amine salt compound accounts for 20-35 weight percent, the polyamine polymer accounts for 2-8 weight percent, and the iron-based inorganic salt accounts for 55-70 weight percent. Here, weight percent means wt%.

[0030] In more detail, the alkyl amine salt compound is selected from alkyl dimethylbenzene quaternary ammonium salts, alkyl trimethyl quaternary ammonium salts, dialkyl dimethyl quaternary ammonium salts, ester quaternary ammonium salts , and the group consisting of amide-amine quaternary ammonium salts. The polyamine polymer is selected from the group consisting of polyamine, polydiallyldimethylammonium chloride, dimethylamine / epichlorohydrin copolymer, and polyhydroxypropyldimethylammonium chloride. The iron-based inorganic salt is selected from the group consisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com