Method for testing use performance of dewatering rust preventive oil

A test method and technology of anti-rust oil, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that only the anti-rust or dehydration of dehydrated anti-rust oil can be evaluated alone, and the actual effect of dehydrated anti-rust oil cannot be quickly tested. , can not describe the dehydration, rust prevention and oil film condition of dehydration and rust prevention oil at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

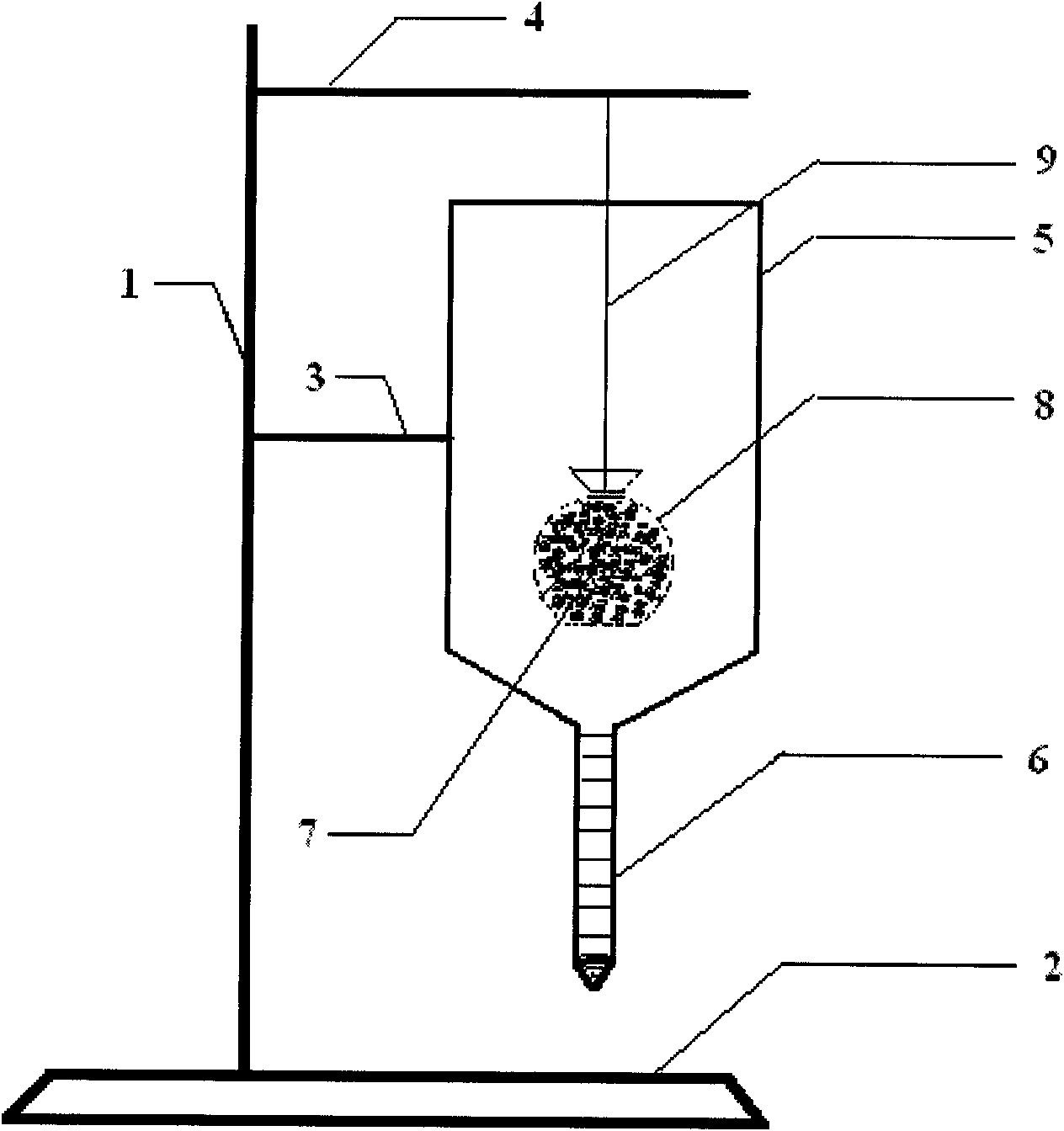

Image

Examples

Embodiment 1~2

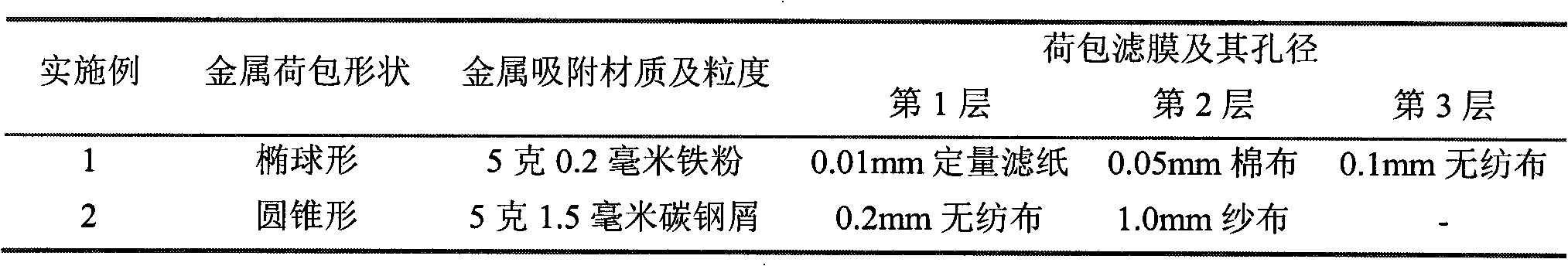

[0028] Wrap the metal adsorption material in the filter membrane to obtain metal purses, see Table 1 for details of each metal purse.

[0029] [Example 1] The metal purse was fully soaked and adsorbed in water for 60 seconds, and then drained for 30 seconds. Inject different types and brands of dehydrated antirust oils A, B, C, D, E and F on the market into the dehydration tank with a metering tube. Dip the drained metal purse into 450 grams of dehydrated antirust oil to be tested, and suspend it in the dehydration tank. Start timing from the moment when the metal purse is completely immersed in the dewatered antirust oil to be tested, and record the time when the first drop of water falls and the water volume reading in the metering tube, so as to evaluate the dehydration of the dehydrated antirust oil to be tested. The test results are shown in Table 2.

[0030] Table 1

[0031]

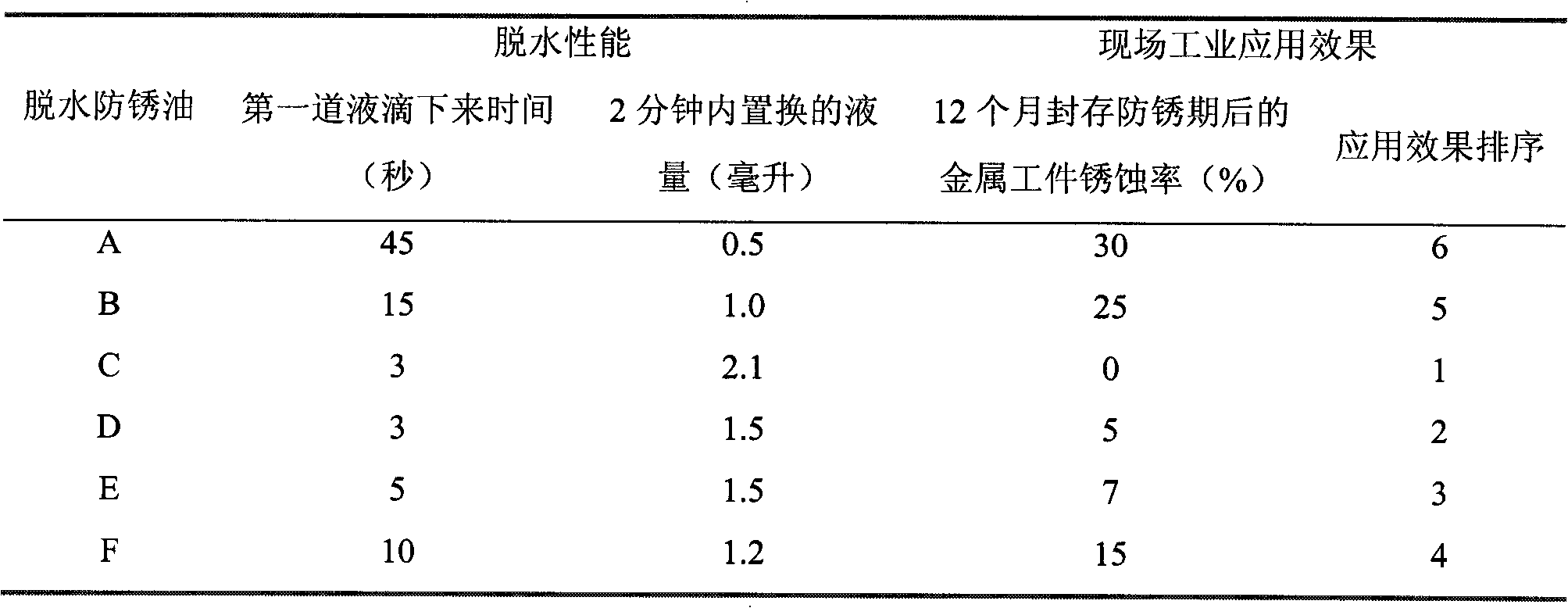

[0032] Table 2

[0033]

[0034] According to the field industrial application effect...

Embodiment 3

[0036] The metal purse of [Example 2] was fully soaked and adsorbed in water for 90 seconds, and then drained for 20 seconds. Inject the oil to be tested into the dehydration tank with metering tube. Dip the drained metal purse into 600 grams of the oil to be tested and hang it in the dehydration tank. Start timing from the moment the metal purse is fully immersed in the oil to be tested, record the time when the first drop of water falls and the water volume reading in the metering tube. The dehydration performance of different types and brands of dehydrating antirust oils A, B, C, D, E, F and G and one non-dehydrating antirust oil in the market was tested. Take the metal purse out of the oil to be tested, and evaluate the dehydration antirust oil A, B, C, D, E, F and G and a non-dehydration antirust oil according to the rust imprint on the purse filter membrane and measure the area of the rust Oil rust resistance.

[0037] Put the metal purse on the filter paper, and ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com