Suspension-type loose fiber dryer

A loose fiber and hanging technology, applied in the field of dehydration equipment, can solve the problems of low production efficiency of dehydration machines, long operation time of workers, high labor intensity, etc., and achieve the effect of durable machines, high production efficiency and low safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

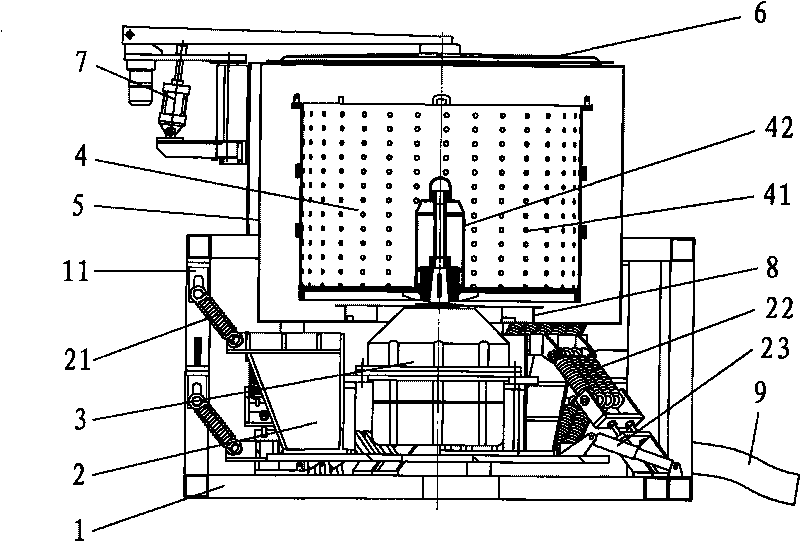

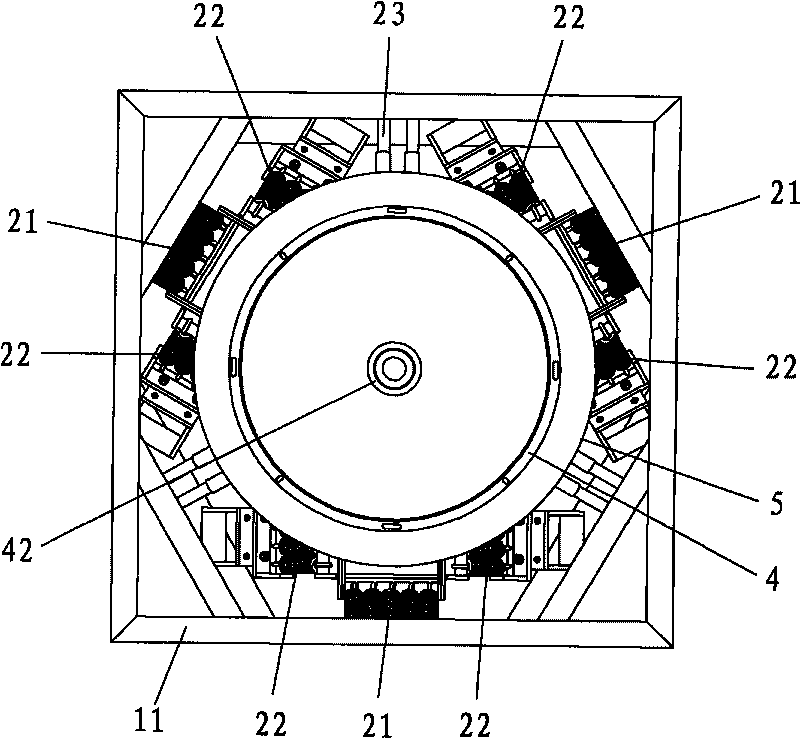

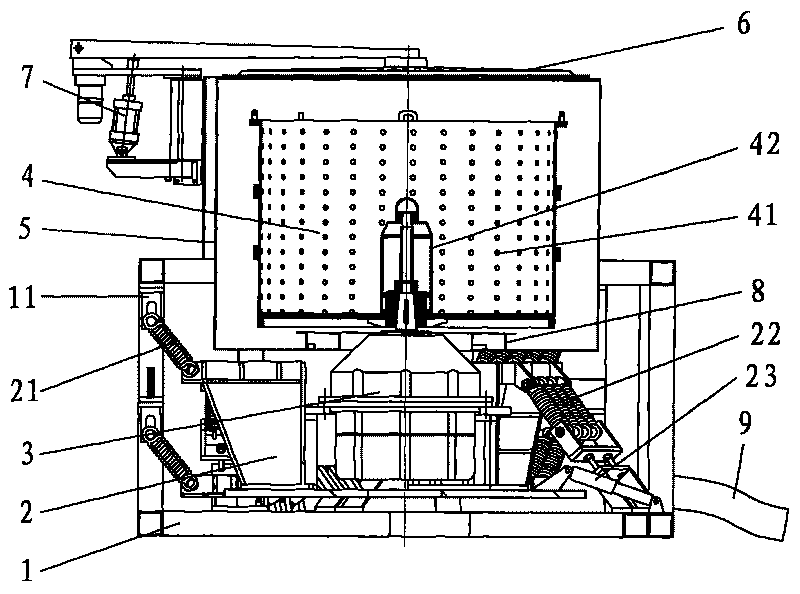

[0010] refer to figure 1 , figure 2 , a hanging type loose fiber dehydrator according to the present invention, comprising a frame 1, a motor support 2 disposed in the frame 1, a motor 3 disposed on the motor support 2, a motor 3 disposed above the motor 3 and connected to the motor shaft through transmission. The inner cage 4, the inner cage 4 is provided with a water outlet hole 41, and the inner cage 4 is fixed with a casing 5, and the top of the casing 5 is provided with a machine cover 6 and a pneumatic assembly 7 for opening the cover. 21 is suspended on the side wall 11 of the frame, and the motor bracket 2 is also connected with a downward tension spring 22 connected to the bottom of the frame, and a shock absorber 23 is connected between the motor bracket 2 and the bottom of the frame, A water retaining ring 8 is provided at the contact between the inner bottom of the casing 5 and the motor 3 , and the casing 5 is connected with a drain pipe 9 .

[0011] The above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com