Coal tar pretreatment method

A coal tar and pretreatment technology, which is applied in the direction of tar extraction and processing through chemical methods, can solve the problems of large amount of chemical agents, aggravating the difficulty of coal tar pretreatment, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

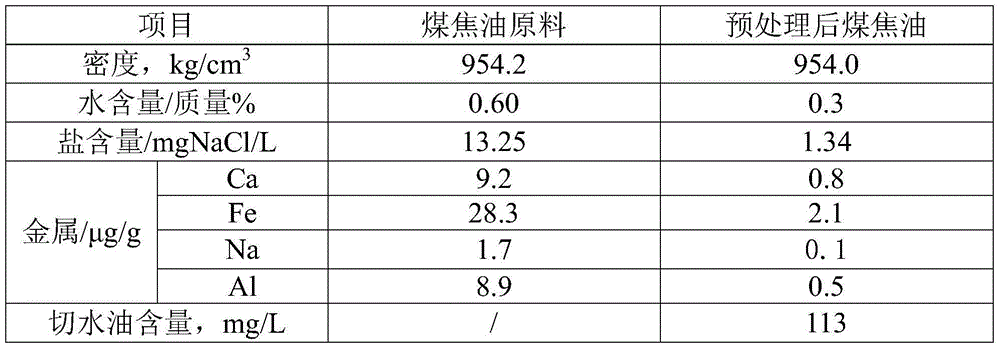

Embodiment 1

[0036] This embodiment is used to illustrate the method for coal tar pretreatment of the present invention.

[0037] Preheating coal tar (coal dry distillation coal tar produced in Xundian, Yunnan Province) to 130°C, and preheating an aqueous solution (concentration of 0.15% by weight) of demetallization agent YX-F-101 (commercially available) to 80°C;

[0038] The fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are 316 series stainless steel wires (commercially available), the aspect ratio of the mass transfer space cylinder is 60:1, and the volume of the fiber liquid film contactor is 0.3L ;

[0039] The preheated coal tar is 6kg / h according to the feed rate, and the liquid hourly space velocity is 20h -1 Add fiber liquid membrane contactor, the aqueous solution of the demetallizing agent YX-F-101 after the preheating is 1.2kg / h (wherein with respect to coal tar, the water injection rate is 20% by weight, the demetallizing agent's Con...

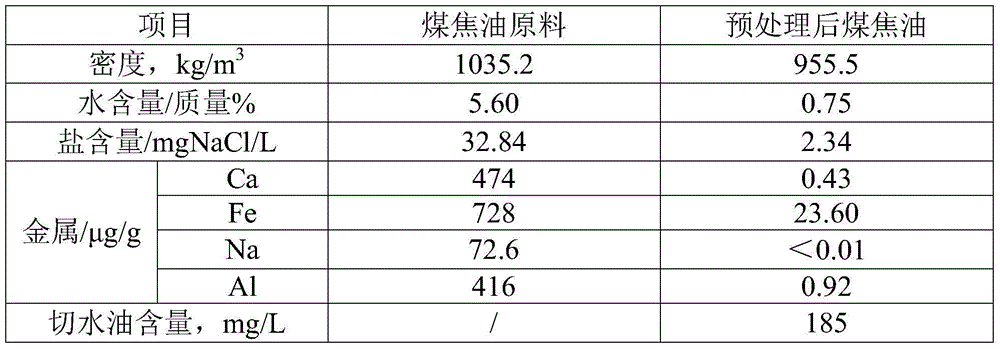

Embodiment 2

[0045] This embodiment is used to illustrate the method for coal tar pretreatment of the present invention.

[0046] Coal tar (coal dry distillation coal tar produced in the Hami area of Xinjiang) and diluent oil (the liquid phase hydrogenation of the coal tar produces oil with a density of 920.1kg / m 3 ) is mixed according to the mass ratio of 1:2, and the density of the obtained pretreatment mixture-1 is 955.5kg / m 3 . Preheat the pretreatment mixture-1 to 80°C, and preheat the aqueous solution (concentration of 0.15% by weight) of the demetallizing agent YX-F-101 (commercially available) to 60°C;

[0047] The fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are 316 series stainless steel wires (commercially available), the aspect ratio of the mass transfer space cylinder is 60:1, and the volume of the fiber liquid film contactor is 0.3L ;

[0048] The preheated pretreatment mixture-1 is 12kg / h according to the feed rate, and the liqu...

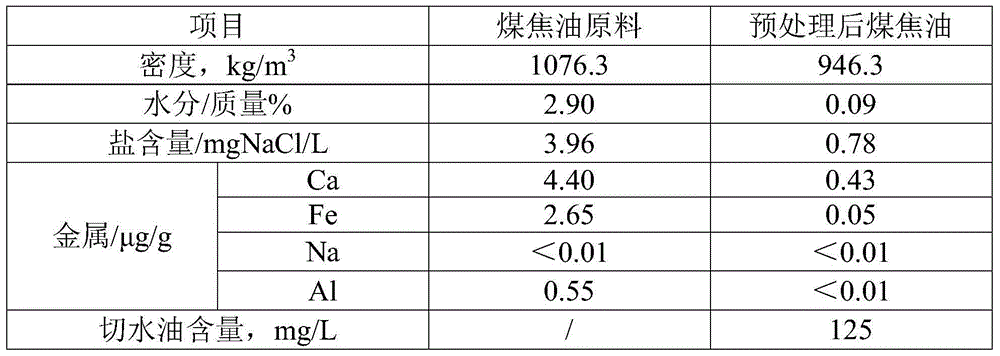

Embodiment 3

[0055] This embodiment is used to illustrate the method for coal tar pretreatment of the present invention.

[0056] Coal tar (produced from the by-product coal tar of the semi-coke dry distillation process in Yulin, Shaanxi) and diluent oil (coal tar hydrogenated to produce oil greater than 170 ° C distillate, density 875.8kg / m 3 ) is mixed according to the mass ratio of 1:1.5, and the density of the obtained pretreatment mixture-2 is 946.3kg / m 3 . Preheat the pretreatment mixture-2 to 120°C, and preheat the aqueous solution (concentration of 0.15% by weight) of demetallizing agent ST-99 (commercially available) to 60°C;

[0057] The fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are 5 mm glass fiber filaments (commercially available) from the glass fiber factory. The aspect ratio of the mass transfer space cylinder is 50:1, and the fiber liquid film contactor The volume is 0.3L;

[0058] The preheated pretreatment mixture-2 is 12kg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com