Apparatus for washing and squeezing mop

A mop cleaning and dehydrating machine technology, applied in the direction of cleaning machinery, cleaning carpets, cleaning floors, etc., can solve the problems of limiting the application range of equipment, increasing the volume of the body, and troublesome fixed installation, etc., to achieve easy body cleaning, water saving, and cleaning The effect of working convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments of the accompanying drawings.

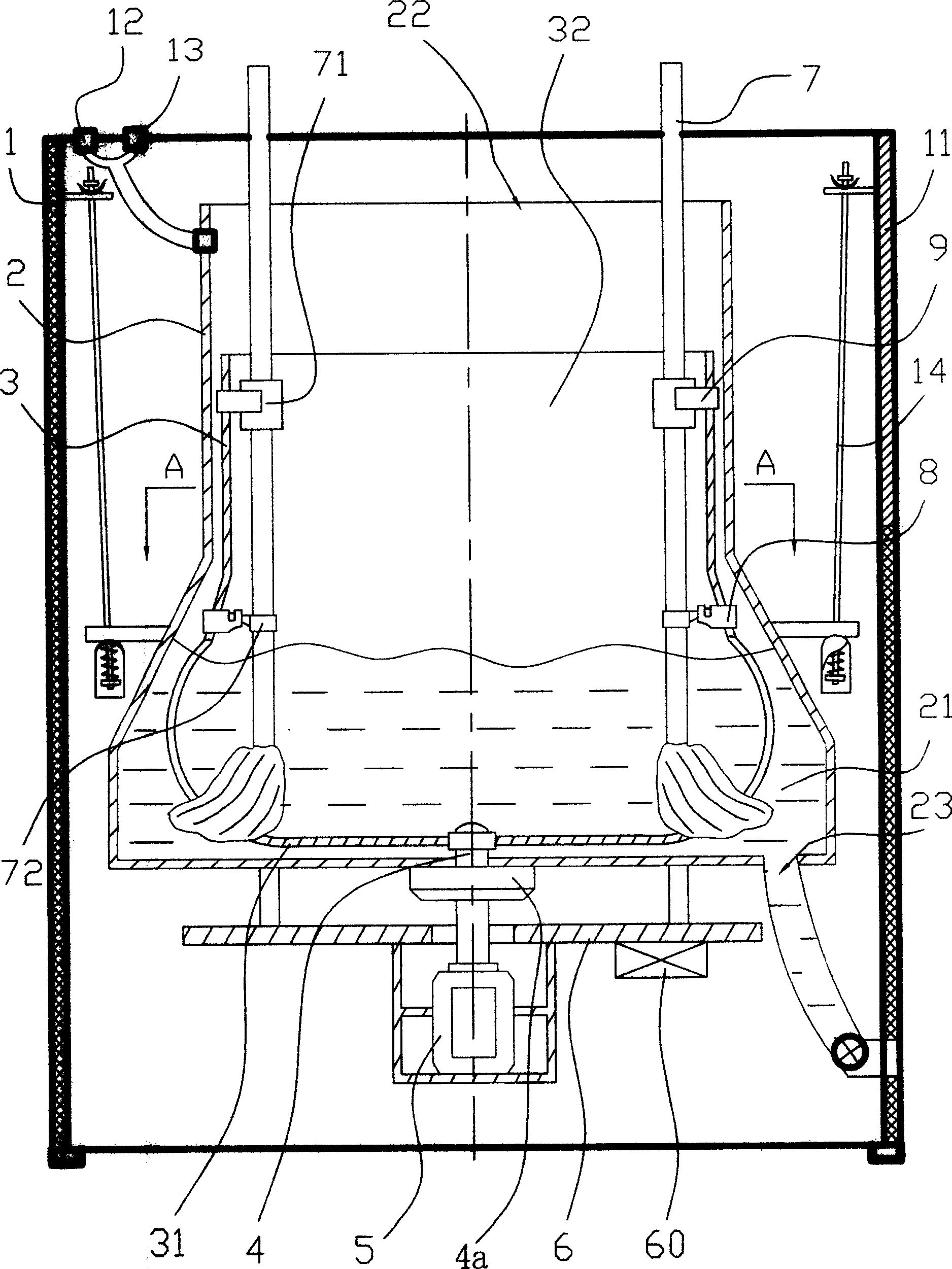

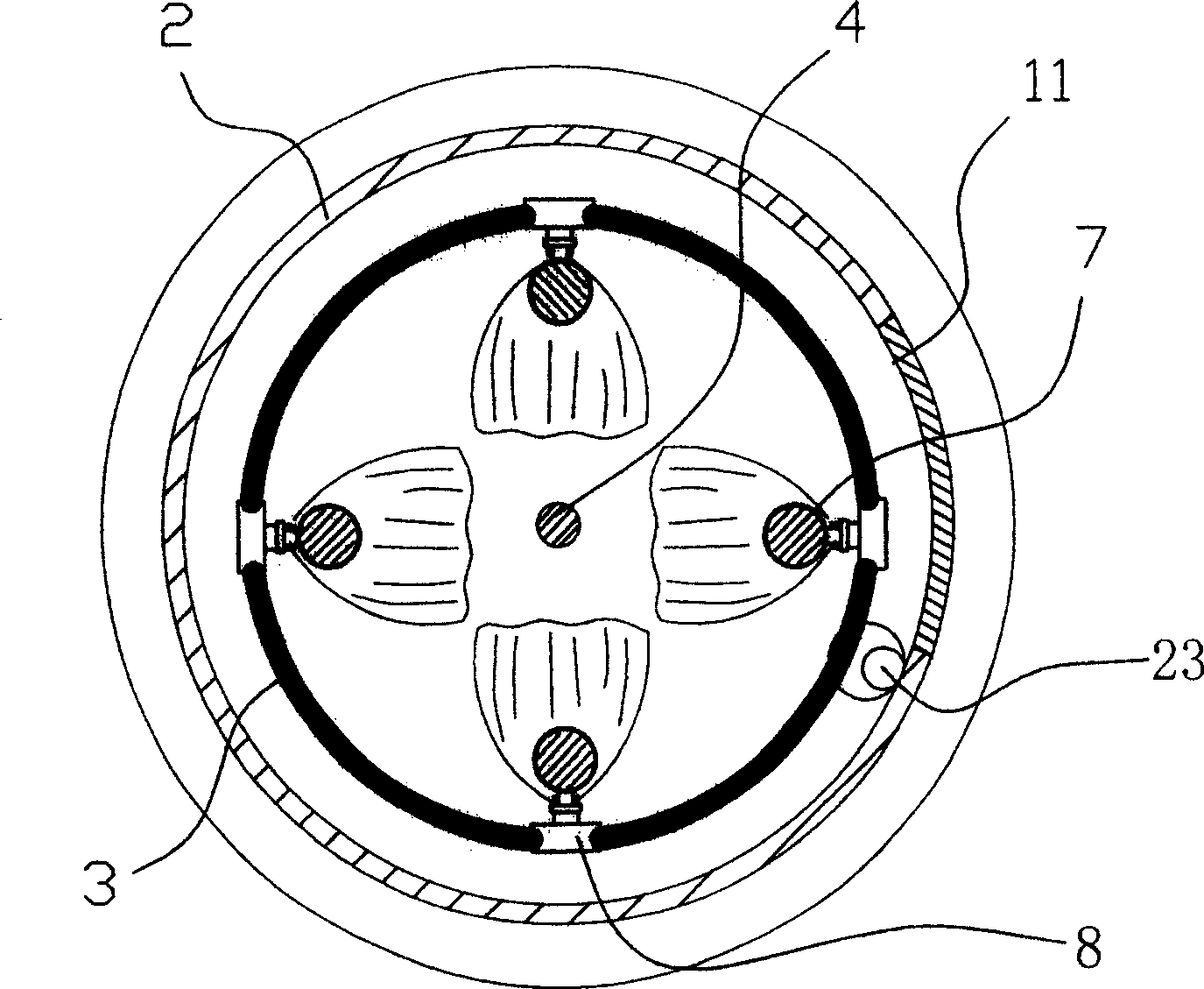

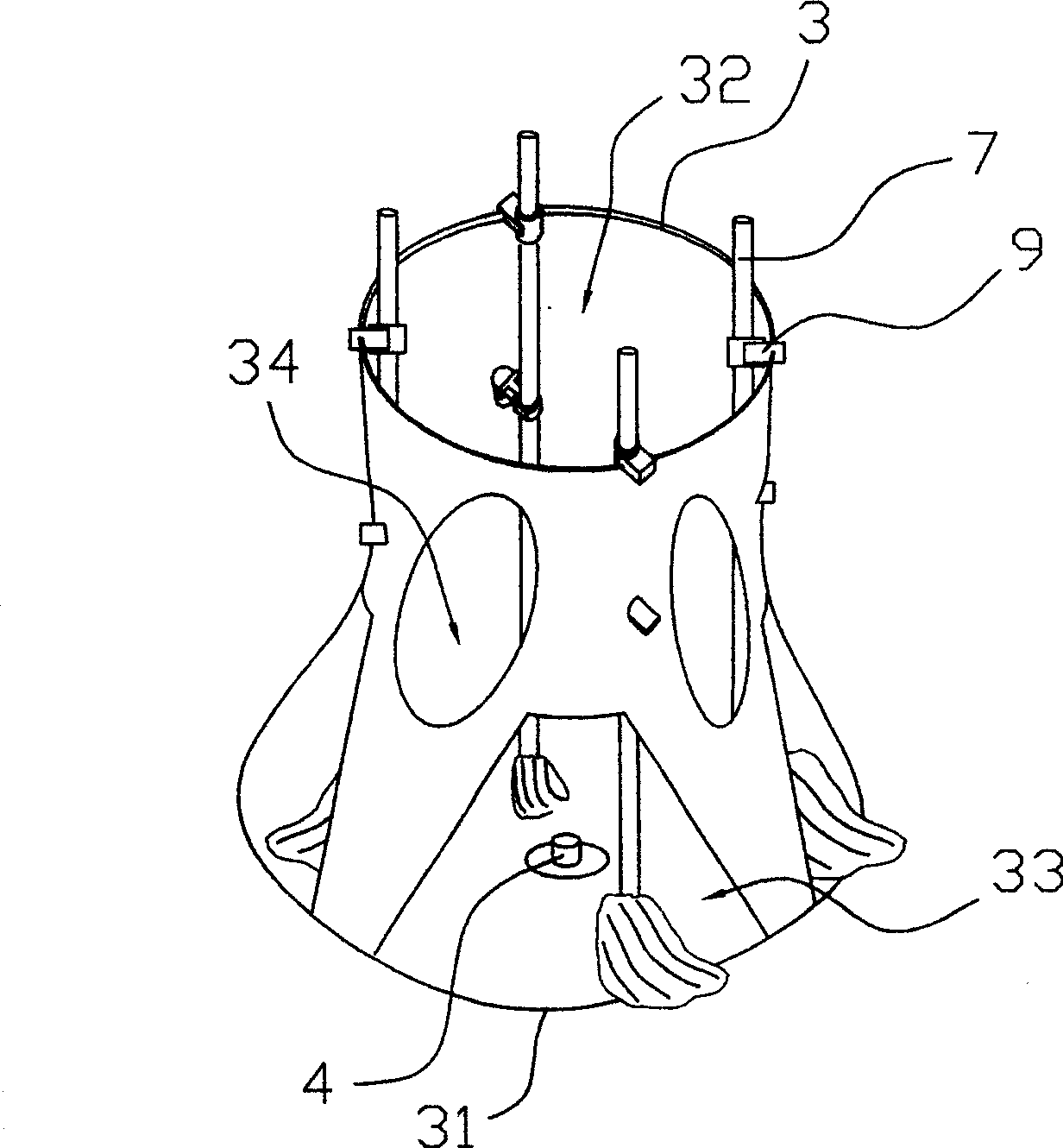

[0023] Option one, such as figure 1 As shown in Fig. 8, the mop cleaning and dehydrating machine of this embodiment includes a water tank 2, and an opening 22 is formed on the upper end of the water tank 2 to allow the mop 7 to protrude. See figure 1 shown. A rotatable ring-shaped washing rack 3 is arranged inside the tub 2, the inner cavity 32 of the annular washing rack 3 communicates with the inner cavity 21 of the tub, and the bottom 31 of the ring-shaped washing rack 3 is connected to the tub 2 through a transmission device. The motors 5 below are linked together to be interlocked together. On the inner sidewall of the ring-shaped washing rack 3 , there are clamping frames that can vertically fix the mop 7 at intervals. There are four groups of clamping frames, and these clamping frames are evenly distributed and fixed on the circumferential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com