Tuber natural wind dehydration device

A technology of dehydration equipment and natural wind, applied in the fields of application, food processing, food science, etc., can solve the problems of high cost of wooden frames, slow speed of wooden frames, and mold generation, so as to reduce labor intensity, improve production efficiency, The effect of shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

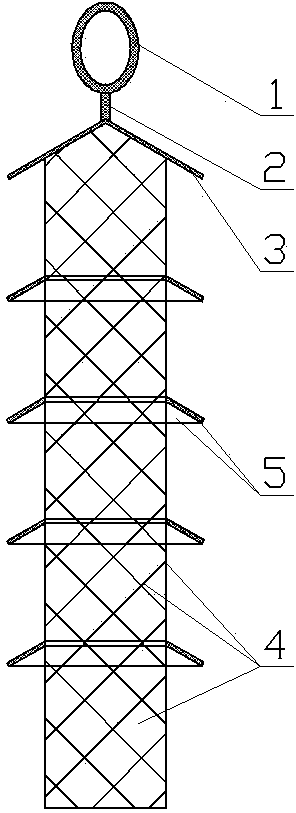

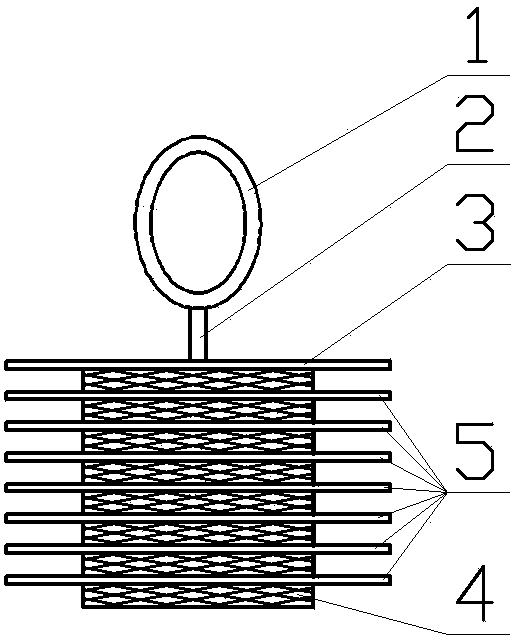

[0062] Stem natural wind dehydration equipment of the present invention mainly comprises two parts: stem wind dehydration rack and stem wind dehydration mesh bag 6;

[0063] Stem air dehydration frame mainly includes base 7, pillar 8, cross frame 9, transverse load-bearing rod 10; described base 7 cooperates with the outer cone surface 15 of the lower end of pillar 8 through the inner taper hole 17 in the middle and is fixed, and cross frame The longitudinal taper hole 14 of 9 is fixed by cooperating with the upper end face of the pillar 8 or the outer taper surface 15 of the lower end. There is a horizontal bearing on the horizontal frame 9, and the horizontal bearing rod 10 is inserted into the bearing hole 11 or the bearing groove of the horizontal bearing. 16 on.

[0064] In order to increase the firmness and stability of the connection of the wind dehydration frame for stems and increase the speed of installation and disassembly, the connection and fixation of the pillar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com