Compound sludge dewatering conditioner adaptable to technology for production of building materials from excess sludge as well as preparation method and application of conditioner

A technology for sludge dehydration and excess sludge, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of large dosage of chemicals, insignificant conditioning effect, and inability to act on the water inside the cells, achieving low dehydration costs, Reduce the cost of sludge dewatering and the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

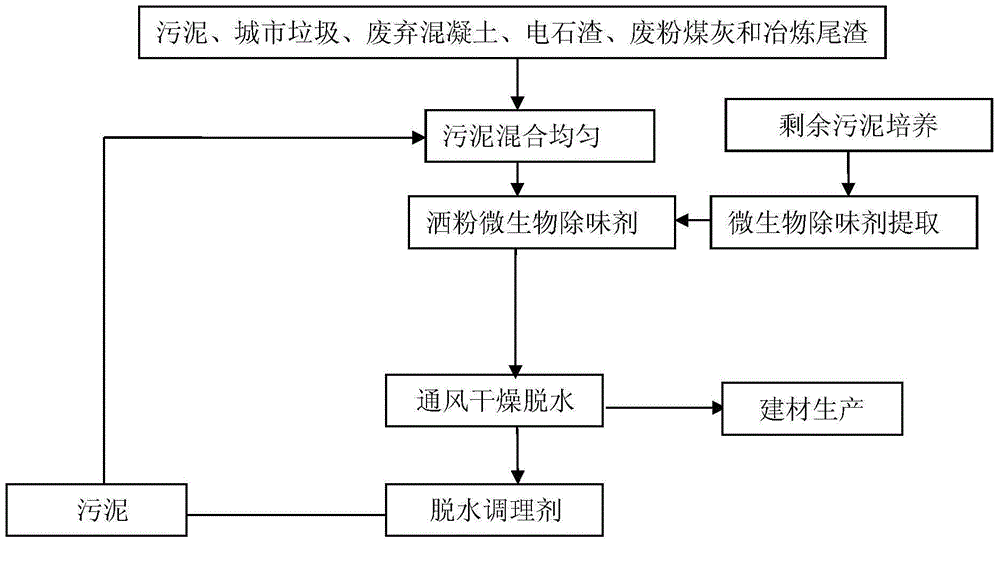

Method used

Image

Examples

Embodiment 1

[0025] First of all, according to the national standard, the composition of residual sludge, waste concrete, fly ash, municipal waste, smelting tailings, carbide slag, and biomass was tested, and according to the composition according to the mass ratio of SiO 2 20%: Al 2 o 3 15%: Fe 2 o 3 8%: CaO 1.0%: C 30%: N 2%, and the rest are elements such as hydrogen and oxygen, mixed evenly, after mixing, evenly sprayed microbial deodorant, ventilated the mixture for 7 days, and obtained a dry sludge dehydration conditioner. The sludge conditioner is added to the sludge, and the amount of the sludge conditioner added is 10% of the mass percentage of the dry weight of the sludge. The building material block is prepared by using the building material molding equipment, and the block is given at 30L / min / kg After ventilating for 6 days, the sludge can be dried and the required raw materials for sludge building materials can be obtained.

Embodiment 2

[0027] First of all, according to the national standard, the composition of residual sludge, waste concrete, fly ash, municipal waste, smelting tailings, carbide slag, and biomass was tested, and according to the composition according to SiO 2 40%: Al 2 o 3 5%: Fe 2 o 3 1%: CaO 3%: C 30%: N 0.25%, and the rest are elements such as hydrogen and oxygen, mixed evenly, after mixing, spray microbial deodorant evenly, ventilate the mixture for 3 days, and obtain a dry sludge dehydration conditioner. The sludge conditioner is added to the sludge, and the amount of the sludge conditioner added is 20% of the mass percentage of the dry weight of the sludge. The building material block is prepared by using the building material molding equipment, and the block is given at 5L / min / kg After ventilating for 7 days, the sludge can be dried and the required raw materials for sludge building materials can be obtained.

Embodiment 3

[0029] First of all, according to the national standard, the composition of residual sludge, waste concrete, fly ash, municipal waste, smelting tailings, carbide slag, and biomass was tested, and according to the composition according to the mass ratio of SiO 2 60%: Al 2 o 3 7%: Fe 2 o 3 6%: CaO 5%: C 15%: N 1%, and the rest are elements such as hydrogen and oxygen, mixed evenly, after mixing, spray microbial deodorant evenly, ventilate the mixture for 5 days, and obtain a dry sludge dehydration conditioner. The sludge conditioner is added to the sludge, and the amount of the sludge conditioner added is 40% of the mass percentage of the dry weight of the sludge. The building material block is prepared by using the building material molding equipment, and the block is given at 20L / min / kg After 10 days of ventilation, the sludge can be dried and the required raw materials for sludge building materials can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com