Compound sludge dewatering conditioner adaptable to incineration treatment technology of excess sludge as well as preparation method and application of conditioner

A technology for sludge dehydration and excess sludge, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of large amount of chemical addition, insignificant conditioning effect, and influence on comprehensive utilization of sludge, and achieves simple and efficient dehydration. Low cost and the effect of reducing the cost of sludge incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

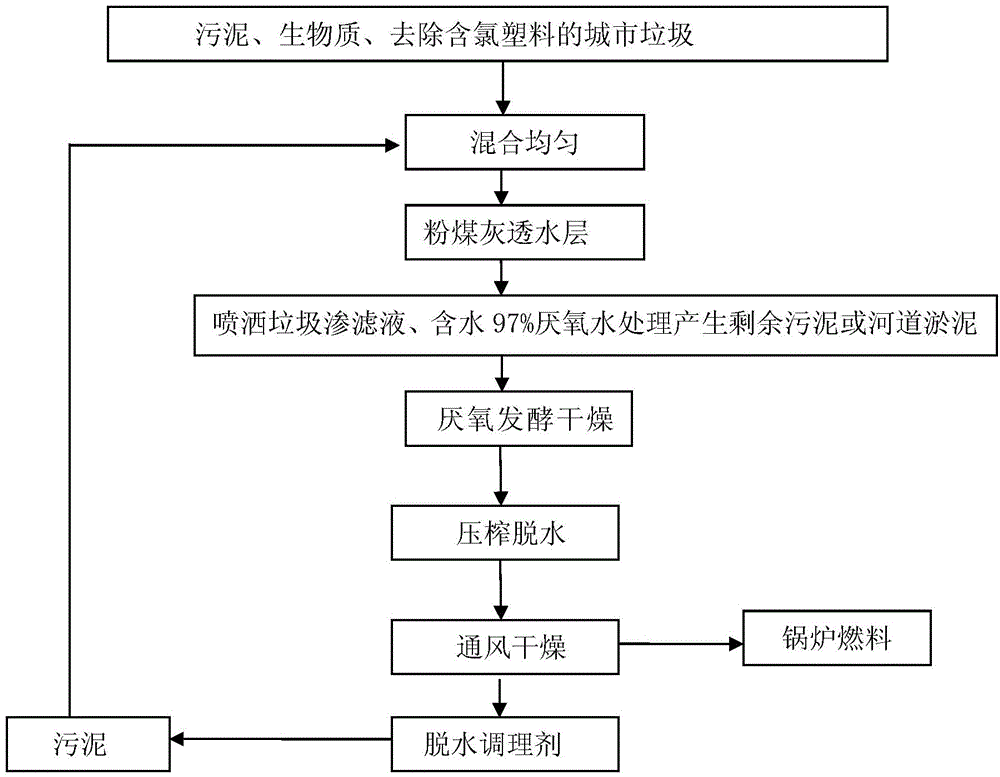

[0022] Sludge, biomass, municipal waste and fly ash for removal of chlorine-containing plastics according to SiO 2 (10%):Al 2 o 3 (5%): Fe 2 o 3 (1%): CaO (10%): C (60%) mixed in mass ratio, other non-heavy metal element content is not limited, mixing method: sludge, biomass and municipal waste are uniformly mixed and a layer of pulverized coal is spread on it ash, and then spray a kind of landfill leachate, accounting for 10% of the total weight, with a total height of 1 meter, and then pile up the second layer, and so on, after the pile, carry out anaerobic fermentation for 10 days, ventilate the fermentation mixture for 20 days, and stack the finished product It can be used as sludge dehydration conditioner.

[0023] The sludge conditioner is added to the sludge, and the amount of the sludge conditioner added is 60% of the mass percentage of the dry weight of the sludge. Stir evenly, perform anaerobic fermentation for 5 days, and ventilate the mixture after fermentation...

Embodiment 2

[0025] Sludge, biomass, municipal waste and fly ash for removal of chlorine-containing plastics according to SiO 2 (20%):Al 2 o 3 (8%): Fe 2 o 3 (5%): CaO (6%): C (50%), (the content of other non-heavy metal elements is not limited) mixed in mass ratio, mixing method: sludge, biomass and municipal waste are evenly mixed and spread a layer on it Fly ash is then sprayed with 97% anaerobic water treatment to produce residual sludge or river silt accounting for the total weight (7%), with a total height of 3 meters, and then pile the second layer, and so on, carry out anaerobic treatment after the pile Ferment for 5 days, stack the finished product and ventilate for 15 days, it can be used as a sludge dehydration conditioner.

[0026] Add the sludge conditioner to the sludge, the amount of the sludge conditioner added is 40% of the mass percentage of the dry weight of the sludge, stir evenly, perform anaerobic fermentation for 3 days, press and dehydrate, and ventilate the m...

Embodiment 3

[0028] Sludge, biomass, municipal waste and fly ash for removal of chlorine-containing plastics according to SiO 2 (15%):Al 2 o 3 (10%): Fe 2 o 3 (10%): CaO (0.5%): C (50%) (other non-heavy metal element content is not limited) mass ratio mixing, mixing method: sludge, biomass and municipal waste are uniformly mixed and then spread a layer of powder on it Coal ash is then sprayed with river channel silt accounting for the total weight (5%), and the total height is 2 meters, and then the second layer is piled up, and so on, and anaerobic fermentation is carried out for 4 days after the pile, and the finished product is ventilated for 5 days, which can be used for sewage treatment. Mud dehydrating conditioner.

[0029] The sludge conditioner is added to the sludge, and the amount of the sludge conditioner added is 10% of the mass percentage of the dry weight of the sludge. Stir evenly, perform anaerobic fermentation for 3 days, and ventilate the mixture after fermentation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com