Room temperature dehydration method for hogwash oil with high-water uptake resin

A kind of technology of super absorbent resin and stagnant oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

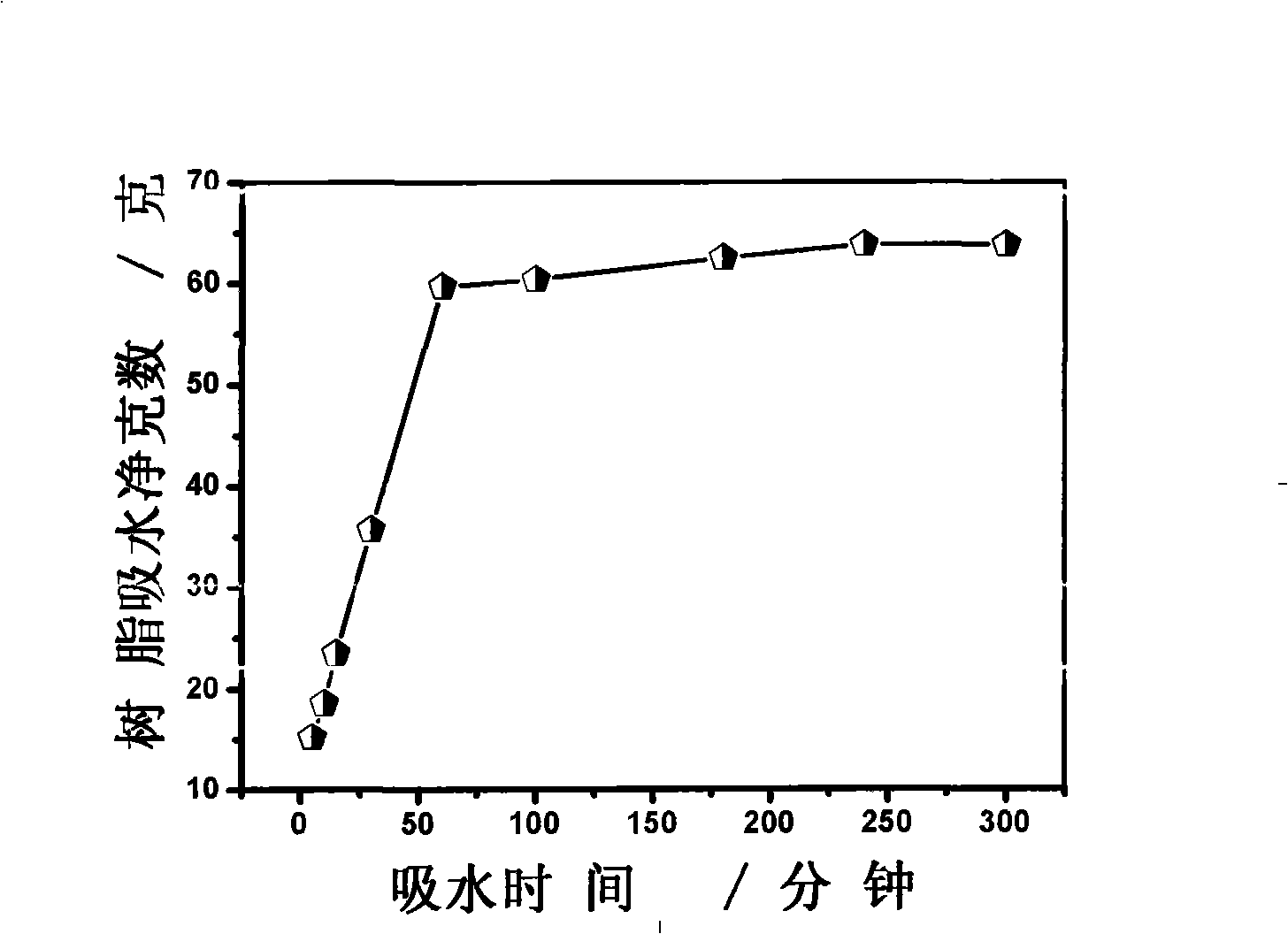

Image

Examples

Embodiment 1

[0021] The selected superabsorbent resin is sodium-based bentonite-acrylic acid-starch copolymer; the superabsorbent resin is sodium-based bentonite added to the acrylic acid-starch graft copolymer, and the dry product of the acrylic acid-starch graft copolymer: sodium-based The weight percentage of bentonite is 58%: 442%; this chemical feature is consistent with the polymer "the ash value obtained by burning at a temperature of 630°C for 6 hours is 46wt.%"; the superabsorbent resin The appearance is gray particles, the particle size distribution of the particles is 50-200 mesh, of which 50-100 mesh particles account for 75wt.%, 100-200 mesh particles account for 25wt.%; the loose density of the particles is 1g / cm 3 , The stocky density is 1.04g / cm 3 ; 1 gram of the superabsorbent resin particles can absorb distilled water in the range of 120 ± 5 grams;

[0022] Collect hogwash oil, obtain density after filtering off solid matter and clarification is 0.934g / cm 3 Aqueous hogw...

Embodiment 2

[0025] The difference from Example 1 is: at room temperature, according to 1 liter of the water-containing hogwash oil, 100 grams of superabsorbent resin was added, and at room temperature, the superabsorbent resin was added to the above-mentioned water-containing hogwash oil, and shaken with a shaker for 1 Minutes, then stand still, start a shaking table every 1 hour and shake for 1 minute afterwards, filter and discharge the material after shaking 8 times, all the other operations are the same as Example 1, and the weight percent that obtains that this water-containing hogwash oil contains water is 1.6wt.%. Using this method, the percentage of dehydration of the superabsorbent resin at room temperature is 51.81%.

Embodiment 3

[0027] The difference from Example 1 is that at room temperature, 75 grams of superabsorbent resin is added to 1 liter of the water-containing hogwash oil, and at room temperature, the superabsorbent resin is added to the above-mentioned water-containing hogwash oil, and shaken with a shaker for 1 Minutes, then stand still, start a shaking table every 1 hour and shake for 1 minute afterwards, filter and discharge after shaking 8 times, all the other operations are the same as Example 1, and the weight percentage that obtains this water-containing hogwash oil water content is 1.5wt.%. Using this method, the percentage of dehydration of the superabsorbent resin at room temperature is 54.82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com