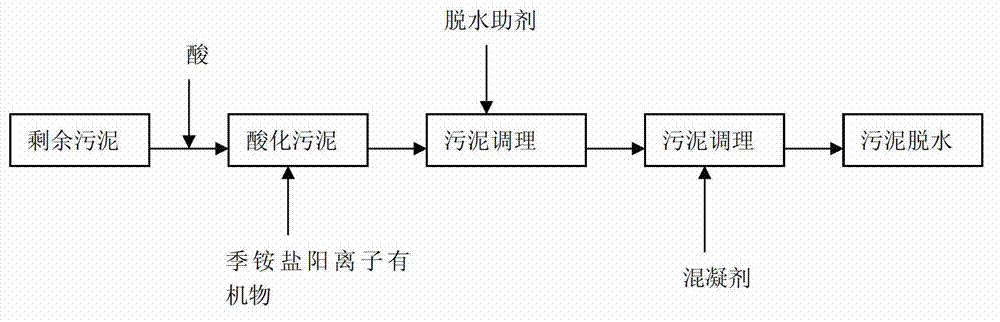

Method for conditioning and dehydrating residual sludge

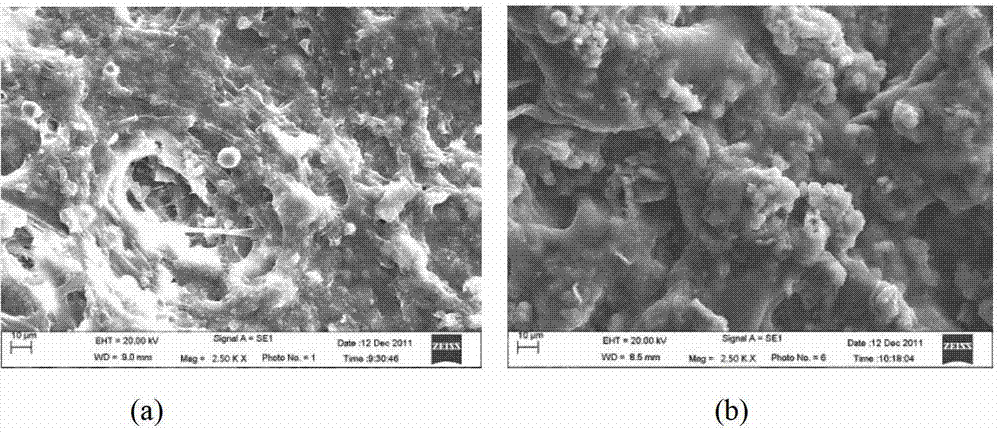

A technology for excess sludge and sludge, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve problems such as difficulty in filtering and sticking to filter cloth, smaller sludge floc particles, affecting practical applicability, etc. The effect of dewatering cost, improving dewatering performance and reducing sludge moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

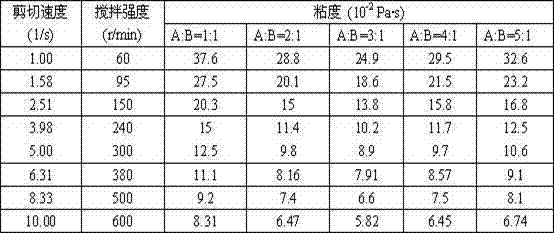

Embodiment 1

[0033] Add 200kg of excess sludge with a moisture content of 90.5% in a sewage treatment plant to 1.0 mol / L sulfuric acid (H 2 SO 4 ) solution is adjusted to a pH value of 4.6; adding quality quaternary ammonium salt cationic organic matter (tetradecyl dimethyl benzyl ammonium chloride and cetyl trimethyl ammonium chloride with a molar ratio of 6.6% of sludge dry weight 2.5:1), with a stirring intensity of 100r / min, stirring for 15 min; after that, adding silica (SiO 2 ), with a stirring intensity of 300r / min, stirring for 5 min; then, adding a coagulant polyaluminum chloride (PAC) with a mass of 2.0% of the dry weight of the sludge to the sludge, and stirring at a stirring intensity of 120r / min, Stirring for 6.5 min; the treated sludge was dewatered by pressure filtration, and the water content of the sludge dropped to 43.6% after dehydration.

Embodiment 2

[0035] 55kg of excess sludge with a water content of 92.7% in a certain sewage treatment plant was added to a hydrochloric acid (HCl) solution with a concentration of 1.3 mol / L to adjust to a pH value of 5.3; Alkyl dimethyl benzyl ammonium chloride and cetyl trimethyl ammonium chloride at a molar ratio of 4:1), with a stirring intensity of 60 r / min, stirring for 10 min; after that, adding mass of Calcium silicate (CaSiO 3 ), with a stirring intensity of 500 r / min, stirring for 3 min; then, adding a coagulant polyaluminum ferric chloride (PAFC) with a mass of 4.4% of the dry weight of the sludge to the sludge, and stirring at a stirring intensity of 150 r / min Stirring intensity, stirring for 5 minutes; the treated sludge is dehydrated by pressure filtration, and the moisture content of the sludge is reduced to 44.9% after dehydration.

Embodiment 3

[0037] Add 1.5 mol / L acetic acid (CH 3 COOH) solution was adjusted to a pH value of 6.0; adding quaternary ammonium salt cationic organic matter (octadecyl dimethyl benzyl ammonium chloride and cetyl trimethyl ammonium chloride in moles) was 8.0% of sludge dry weight ratio 3:1), with a stirring intensity of 50 r / min, stirring for 20 min; after that, adding calcium silicate (CaSiO 3 ), with a stirring intensity of 450r / min, stirring for 4.5 min; then, adding a coagulant polyaluminum ferric chloride (PAFC) with a mass of 3.5% of the dry weight of the sludge to the sludge, and stirring at a stirring intensity of 100r / min , stirred for 5.5 minutes; the treated sludge was dewatered by pressure filtration, and the water content of the sludge dropped to 40.2% after dehydration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com