Blanket with characteristic streaks

A streak and characteristic technology, applied in textiles and papermaking, paper machines, papermaking, etc., can solve the problems of unable to produce wrapping paper, surface stickers, shorten the service life of papermaking felts, affect the water permeability of papermaking felts, and achieve moisture permeability Good, good dehydration effect, and the effect of increasing the void space of the felt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

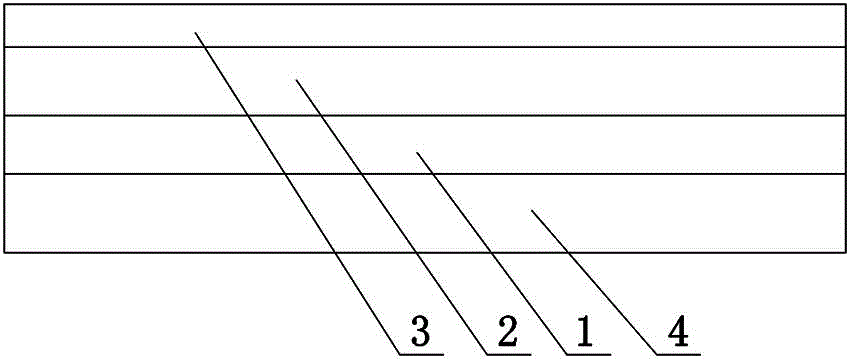

[0017] Such as figure 1 As shown, a characteristic streak blanket is composed of a base fabric bottom net 1, a fiber core layer 2, a fiber surface layer 3 and a fiber back layer 4, and the bottom of the base fabric bottom net 1 is a fiber back layer 4, and the base fabric bottom net 1 is the fiber core layer 2, and the top of the fiber core layer 2 is the fiber surface layer 3. The warp threads of the base fabric base net 1 are composed of thick warp threads and thin warp threads, and the thick warp threads and thin warp threads are arranged at intervals from each other. The diameter of the thin warp threads 0.55mm, the thick warp diameter is 2.8mm, the weft diameter of the base fabric base net 1 is 0.44mm, and the weaving density of the warp of alternate thickness is to contain warp or weft 60 in every 10cm length.

[0018] The warp and weft threads of the base fabric base net 1 are elastic wool-like yarns, and the base fabric base net 1 is composed of a satin weave.

[0019...

Embodiment 2

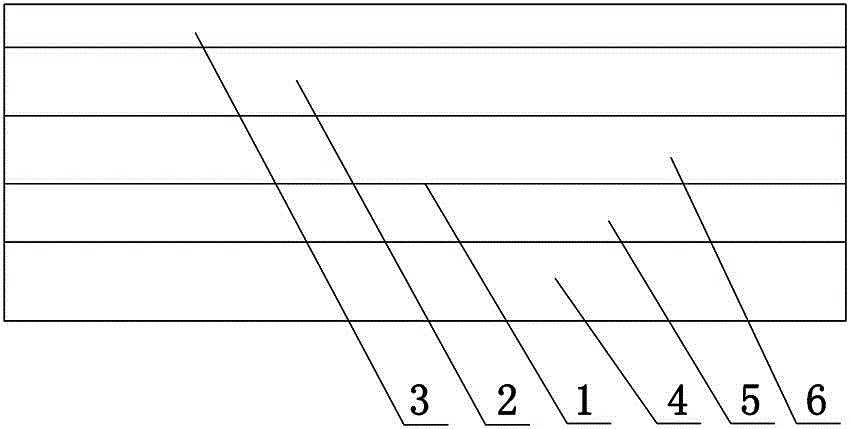

[0021] Such as figure 2 As shown, a characteristic streak blanket is composed of a base fabric bottom net 1, a fiber core layer 2, a fiber surface layer 3 and a fiber back layer 4, and the bottom of the base fabric bottom net 1 is a fiber back layer 4, and the base fabric bottom net 1 above is the fiber core layer 2, and above the fiber core layer 2 is the fiber surface layer 3. The thickness of the warp threads or the weft threads of the base fabric base net 1 are alternately thick and thin, the diameter of the thick thread is 3 mm, and the diameter of the thin thread is 1 mm. Or the weaving density of the weft is 50 warp or weft per 10cm length.

[0022] The base fabric base net 1 is a multi-layer base fabric structure, which includes radial base fabrics 5 and weft base fabrics 6 arranged at intervals, the warps of the radial base fabrics 5 are wool-like yarns with alternate thicknesses, and the wefts are Soluble fibers; the weft threads of the weft base fabric 6 are wool-...

Embodiment 3

[0025] Such as figure 1 As shown, a characteristic streak blanket is composed of a base fabric bottom net 1, a fiber core layer 2, a fiber surface layer 3 and a fiber back layer 4, and the bottom of the base fabric bottom net 1 is a fiber back layer 4, and the base fabric bottom net The fiber core layer 2 is above the fiber core layer 2, and the fiber surface layer 3 is above the fiber core layer 2. The weft threads of the base fabric base net 1 are composed of thick weft threads and thin weft threads, and the thick weft threads and the thin weft threads are arranged at intervals from each other. The diameter of the thin weft threads is 0.46mm, thick weft diameter is 3.7mm, the warp diameter of base fabric base net 1 is 0.46mm, and the weaving density of alternately thick and thin wefts is to contain warp or weft 48 in every 10cm length.

[0026] The warp and weft threads of the base fabric base net 1 are elastic wool-like yarns, and the base fabric base net 1 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com