Process for producing refined montmorillonite by using bentonite

A production process and technology of bentonite, which is applied in the field of refining montmorillonite by using bentonite, can solve the problems that the product purity cannot meet the requirements of fine chemical industry, the secondary separation of fine powder impurities is difficult, and the added value is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

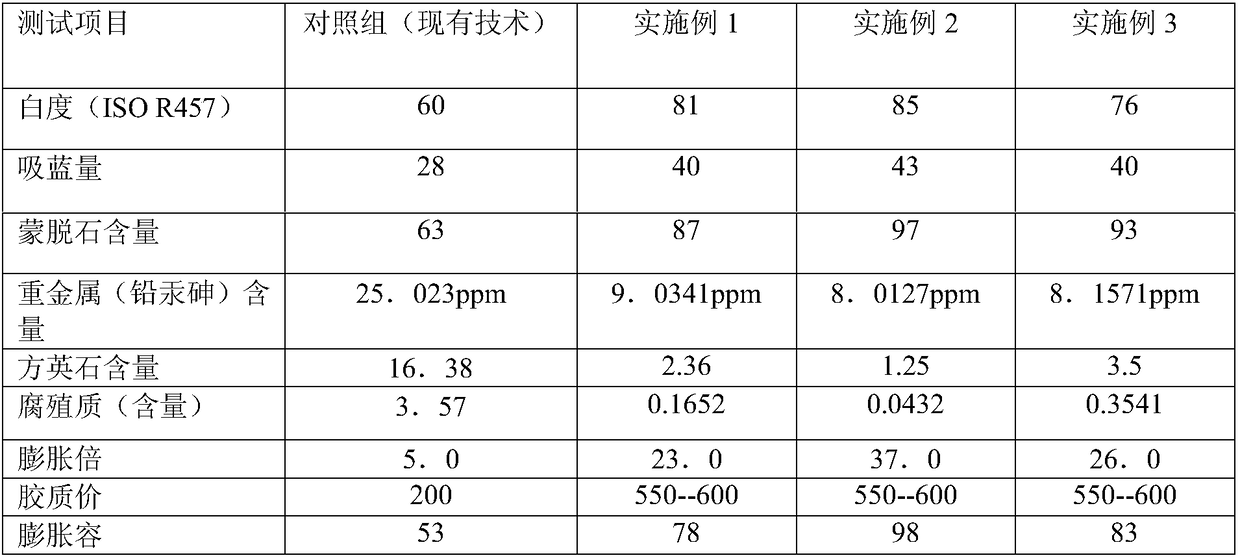

Examples

Embodiment 1

[0032] A production process utilizing bentonite to refine montmorillonite, comprising the steps of:

[0033] Step 1) Bentonite ore slurry making: add water to the mined bentonite and stir to make slurry, and the slurry concentration is controlled at 10%;

[0034] Step 2) Screening the slurry: pass the bentonite slurry through a 200-mesh sieve to remove coarse impurities in the raw ore; the coarse impurities in this step entrain part of the montmorillonite, and sieve the slurry in a second cycle with a 200-mesh sieve.

[0035] Step 3) slurry modification: add a modifier of 2% bentonite equivalent to the slurry concentration, control the pH value of the slurry at 8, and react for 2 hours at a temperature of 50° C., then add water to adjust the slurry to a 2% concentration, and then After adding the viscosity reducer, the slurry is separated by a conical slag remover, and then the slurry is separated by a 325-mesh filter to obtain a high-purity bentonite slurry. Wherein, the mod...

Embodiment 2

[0043] A production process utilizing bentonite to refine montmorillonite, comprising the steps of:

[0044] Step 1) bentonite ore pulping: the bentonite mined is added with water and stirred to make slurry, and the slurry concentration is controlled at 12%;

[0045] Step 2) Screening the slurry: pass the bentonite slurry through a 200-mesh sieve to remove coarse impurities in the raw ore; the coarse impurities in this step entrain part of the montmorillonite, and sieve the slurry in a second cycle with a 200-mesh sieve.

[0046] Step 3) slurry modification: add a modifier of 3% bentonite equivalent to the slurry concentration, control the pH value of the slurry at 9, and react for 2 hours at a temperature of 70°C, then add water to adjust the slurry to a 5% concentration, and then After adding the viscosity reducer, the slurry is separated by a conical slag remover, and then the slurry is separated by a 325-mesh filter to obtain a high-purity bentonite slurry. Wherein, the m...

Embodiment 3

[0054]A production process utilizing bentonite to refine montmorillonite, comprising the steps of:

[0055] Step 1) bentonite ore pulping: the bentonite mined is added with water and stirred to make slurry, and the slurry concentration is controlled at 15%;

[0056] Step 2) Screening the slurry: pass the bentonite slurry through a 200-mesh sieve to remove coarse impurities in the raw ore; the coarse impurities in this step entrain part of the montmorillonite, and sieve the slurry in a second cycle with a 200-mesh sieve.

[0057] Step 3) slurry modification: add a modifier of 4% bentonite equivalent to the slurry concentration, control the pH value of the slurry at 10, and react for 3 hours at a temperature of 90° C., add water to adjust the slurry to 8% concentration, and then After adding the viscosity reducer, the slurry is separated by a conical slag remover, and then the slurry is separated by a 325-mesh filter to obtain a high-purity bentonite slurry. Wherein, the modify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com