Sludge continuous dewatering system

A sludge and pre-dehydration technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as long running time, low dehydration efficiency, and limitation of dehydration efficiency, and achieve the degree of automation High, reduced dehydration cost, good dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0069] (1) Dewatered sludge comes from municipal sludge, and its initial moisture content is about 85%;

[0070] (2) Pre-condition the sludge in step (1), add a biological enzyme wall-breaking agent, the dosage is 4% of the absolute dry weight of the municipal sludge, stir it evenly with a mechanical stirrer under the condition of 30 ° C, and the pre-conditioning time is 25min;

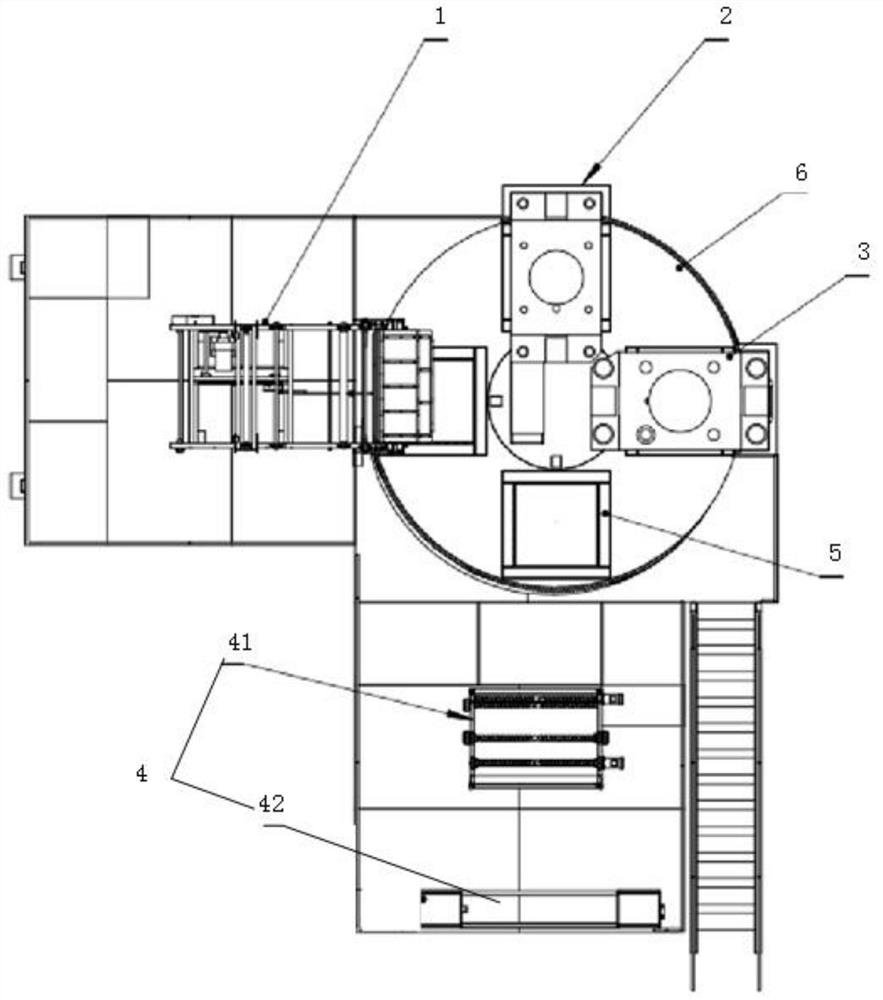

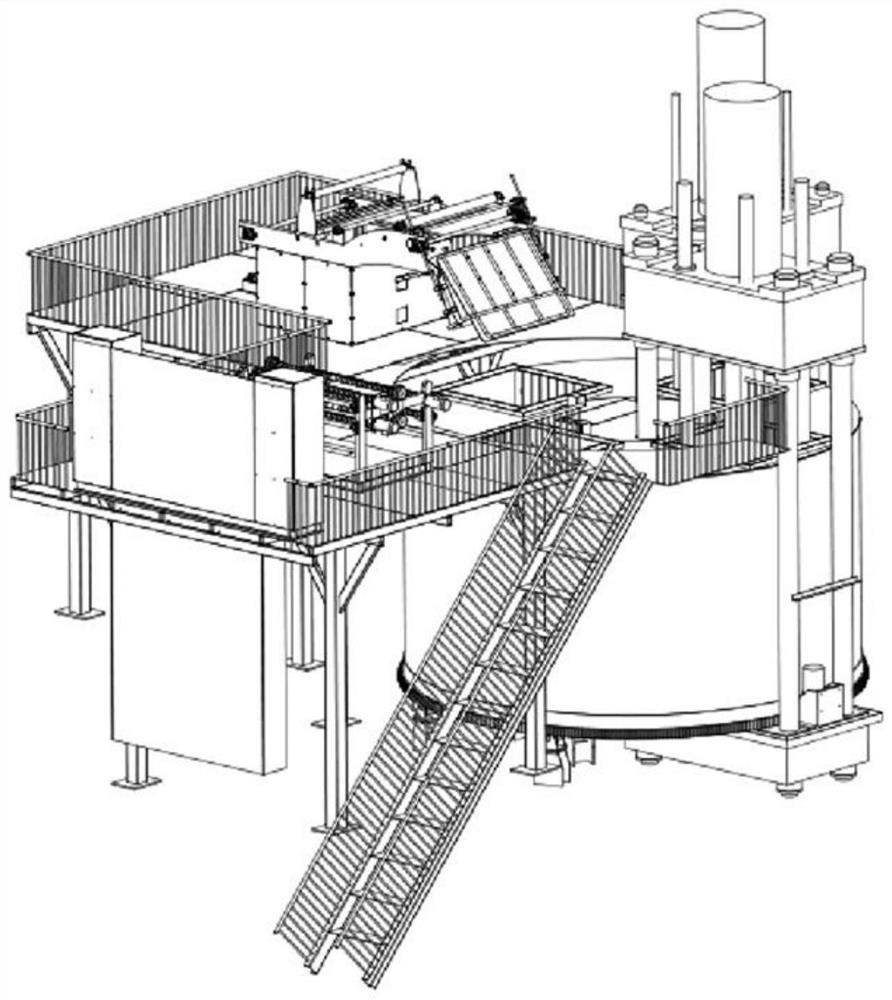

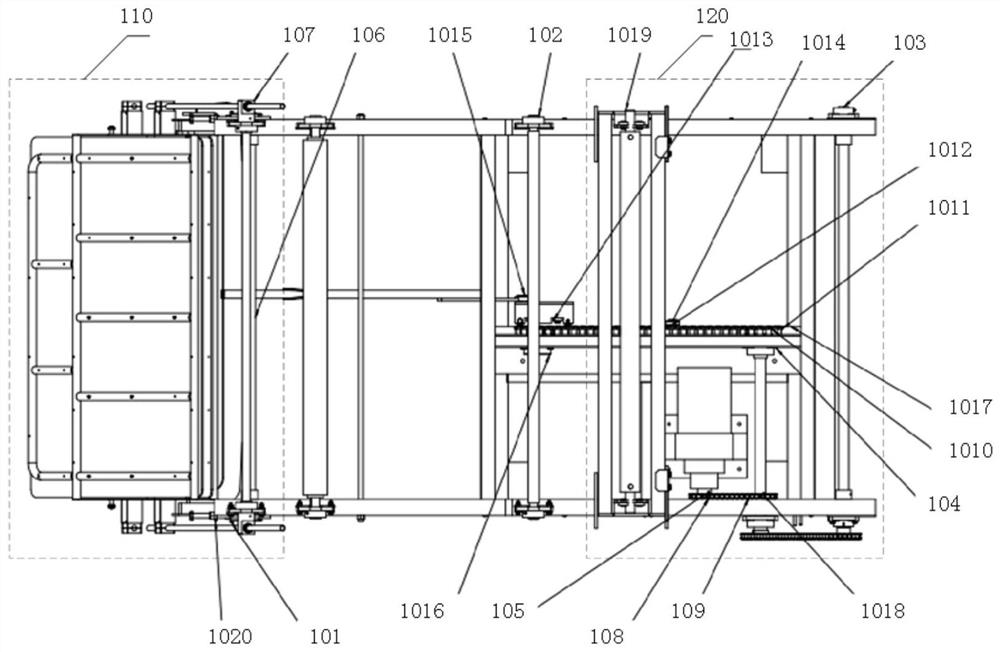

[0071] (3) The pre-conditioned sludge is evenly distributed on the filter cloth through the feeding system, and the double-layer filter cloth is stacked and distributed in the station tank 5 through the feeding device 1, and then the continuous dehydration process is started.

[0072] Since the control disk 6 is provided with four station cylinders 5, when the station cylinder 5 is filled and reaches the corresponding position of the pre-dehydration device 2 through the rotation of the control disk 6, another idle station cylinder 5 is filled. Move to the corresponding position of the feeding device ...

example 2

[0079] (1) Dewatered sludge comes from industrial papermaking sludge, and its initial moisture content is 90%;

[0080] (2) Pre-condition the sludge in step (1), add biological enzyme wall-breaking agent, the dosage is 7% of the absolute dry weight of municipal sludge, stir it evenly with a mechanical stirrer under the condition of 30 °C, and the pre-conditioning time is 30min;

[0081] (3) The pre-conditioned sludge is evenly distributed on the filter cloth through the feeding system, and the double-layer filter cloth is stacked and distributed in the station tank 5 through the feeding device 1, and then the continuous dehydration process is started.

[0082] Since the control disk 6 is provided with four station cylinders 5, when the station cylinder 5 is filled and reaches the corresponding position of the pre-dehydration device 2 through the rotation of the control disk 6, another idle station cylinder 5 is filled. Move to the corresponding position of the feeding device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com