Device for removing heavy metals in sludge by using electro-dynamic method and synchronously and deeply dehydrating sludge

A heavy metal and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of consuming large chemical reagents, affecting land use of sludge, reducing heavy metal content in sludge, etc. , to achieve the effect of improving power utilization, reducing operating costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

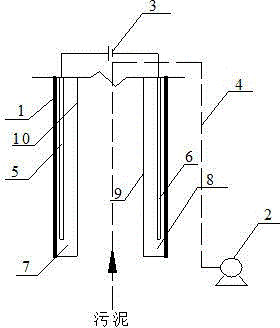

[0024] Such as figure 1 As shown, the device consists of a sludge transfer pipeline 1, a sludge pump 2, a DC power supply 3, a wire 4, an anode 5, a cathode 6, an anode compartment 7, a cathode compartment 8, a cation exchange membrane / porous medium membrane 9, and an anion exchange Membrane / porous medium membrane 10, in which the anaerobic digested sludge flows in the sludge conveying pipeline 1 under the power provided by the sludge pump 2, and the two ends of the DC power source 3 are connected to the anode 5 and the cathode 6 through the wires 4, respectively. Connection, under the action of DC power supply 3, the voltage gradient is set to 10V / cm, which is 14.5V in this case. After 3 hours of treatment, the current is reduced from the initial 70mA to 0mA, which means that the heavy metal ions in the sludge move to the cathode 6 through the cation exchange membrane / porous medium membrane 9, and are concentrated in the concentration tank or finally electrolytically deposited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com