Device and technology capable of combining high-salt content oil field sewage treatment and viscous oil recovery

A combination technology of oilfield sewage and sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining fluid, etc., can solve the problems of oilfield mining, rapid equipment corrosion, large steam consumption, etc., to achieve Avoid the problem of corrosion equipment, solve the effect of low heat transfer efficiency and high-efficiency heat exchange and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

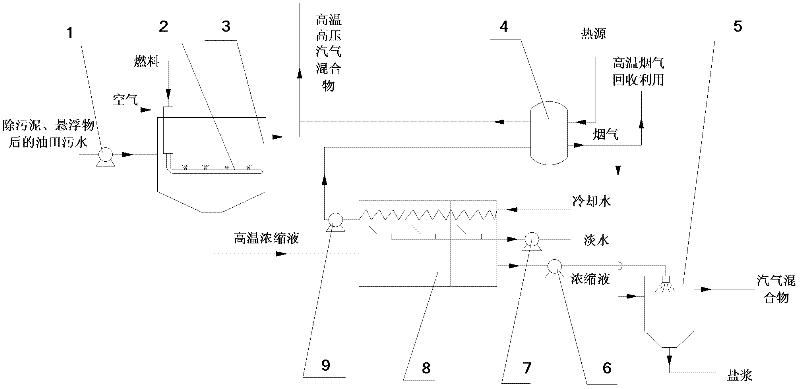

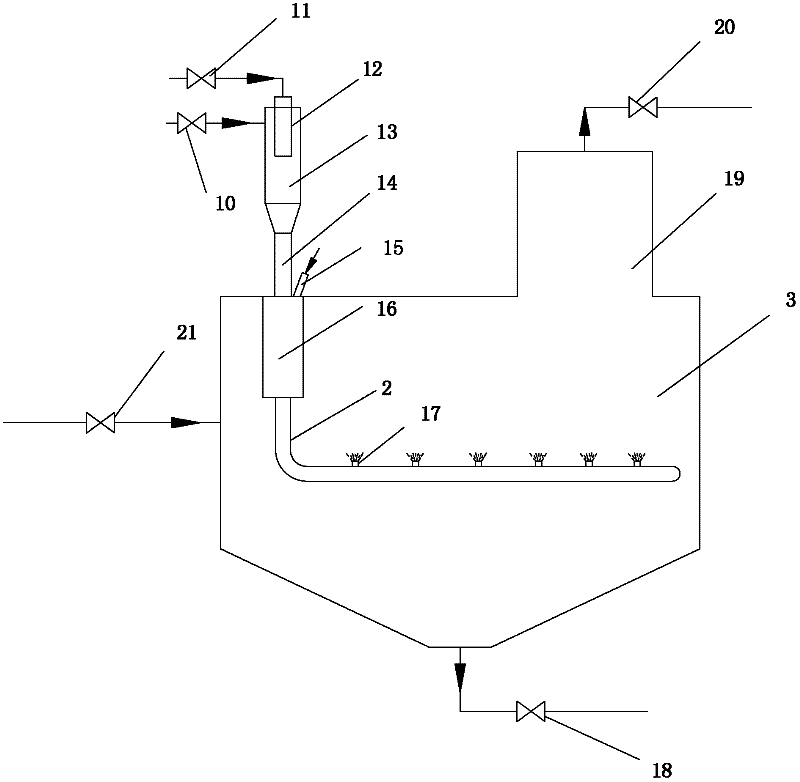

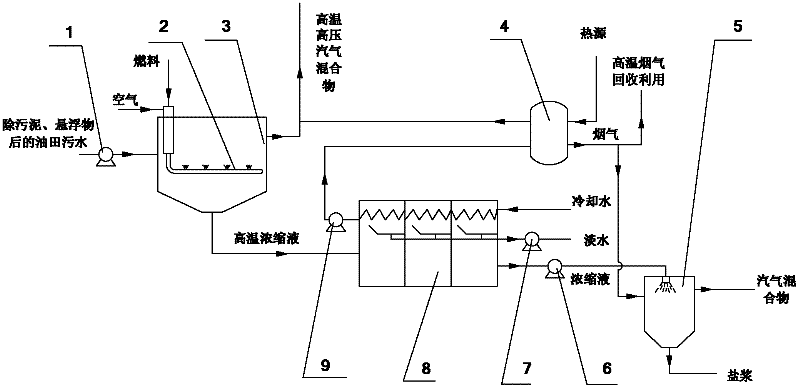

[0035] Such as figure 2 As shown, the specific implementation steps of the high-pressure water incineration evaporator are as follows: first, the fuel and air are respectively matched by the fuel adjustment device (11) and the air adjustment device (10), and are fully mixed in the fuel-air mixing chamber (13). The mixed gas is accelerated in the acceleration tube (14), and then the mixed gas is ejected from the bottom hole to form a mixed jet flow combustion in the combustion chamber (16), and secondary air can be supplemented from the secondary air tube (15) as required to form The cross-fire mixed airflow makes the combustion more complete. Combustion continues to the combustion nozzle (2), after accelerated boosting, the flame is directly injected into the sewage through the combustion nozzle, heat exchange and evaporation are rapid in the evaporation chamber (3), and the secondary (18) is controlled to be discharged, and the secondary steam The pressure and temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com