Sequencing batch limestone slurry wet desulfurization technique

A technology of wet desulfurization and limestone slurry, applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of difficult application of small and medium-sized flue gas and fuel oil flue gas desulfurization devices, complicated system management and operation, and flue gas dust removal. Require high-level problems, achieve the effect of low by-product treatment requirements, simplified process system, guaranteed reaction time and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

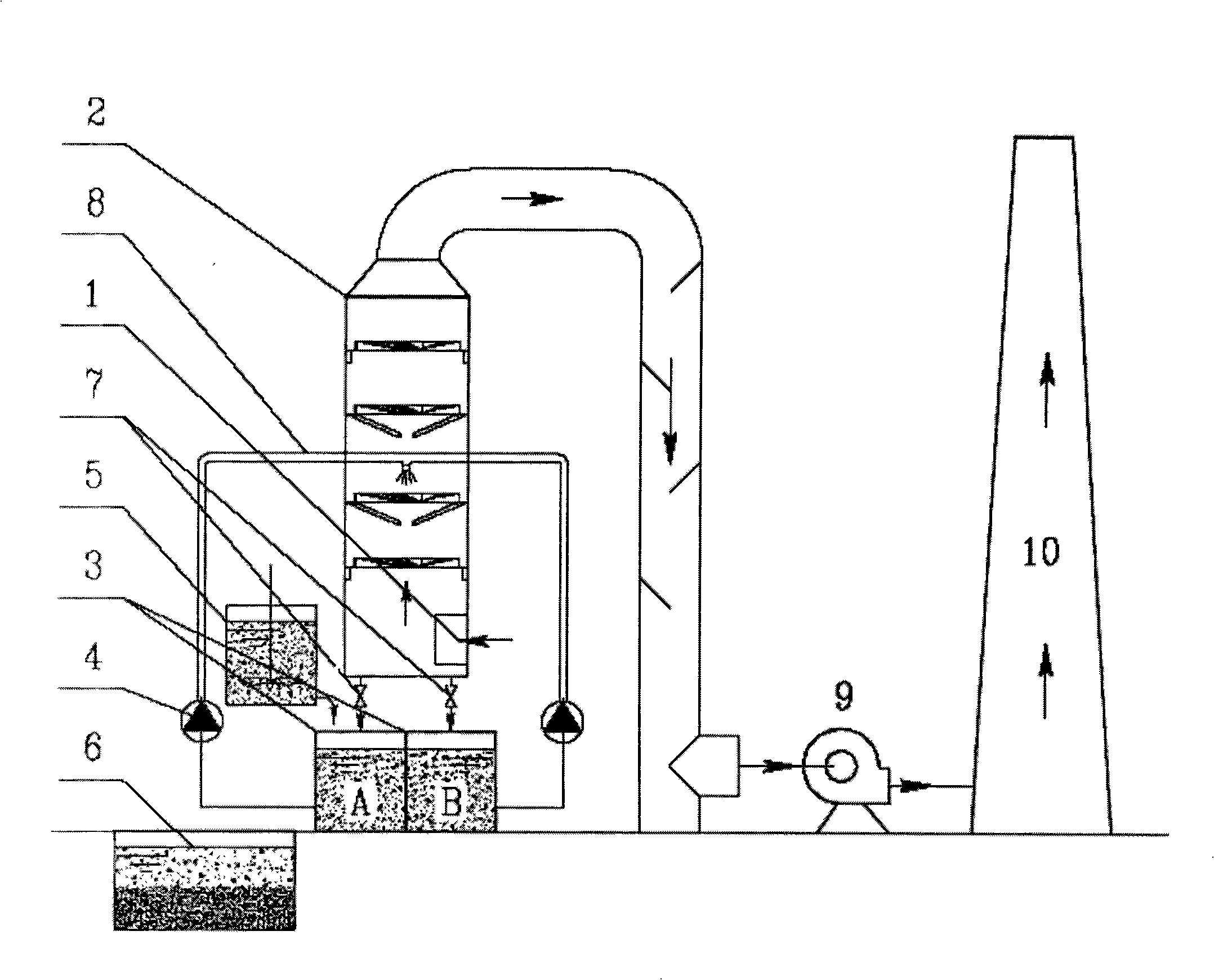

[0038] The sequence batch type limestone slurry wet desulfurization process of the present invention is actually a high-efficiency desulfurization system guaranteed by limestone, which uses limestone slurry as a desulfurization agent sequence batch to absorb and react alternately, uses a high-efficiency tower as a desulfurization device, and uses desulfurization waste residue as a by-product. French desulfurization process.

[0039] Such as figure 1 As shown, the coal-fired flue gas with simple dust removal or fuel oil flue gas without dust removal directly enters the high-efficiency desulfurization tower (2) from the flue gas inlet (1), and the slurry in the limestone slurry pool (3) A pool is used as the first absorption desulfurization, the limestone slurry pool (3) A pool is pumped repeatedly by the circulation pump (4) and the spray pipe (8) to the high-efficiency desulfurization tower (2) to absorb SO 2 At this time, the absorption and reaction are carried out at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com