BOG liquefaction recycling system for liquefied natural gas

A liquefied natural gas, recycling technology, applied in fixed-capacity gas storage tanks, container discharge methods, gas/liquid distribution and storage, etc., can solve the problems of low recycling rate, poor operability, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

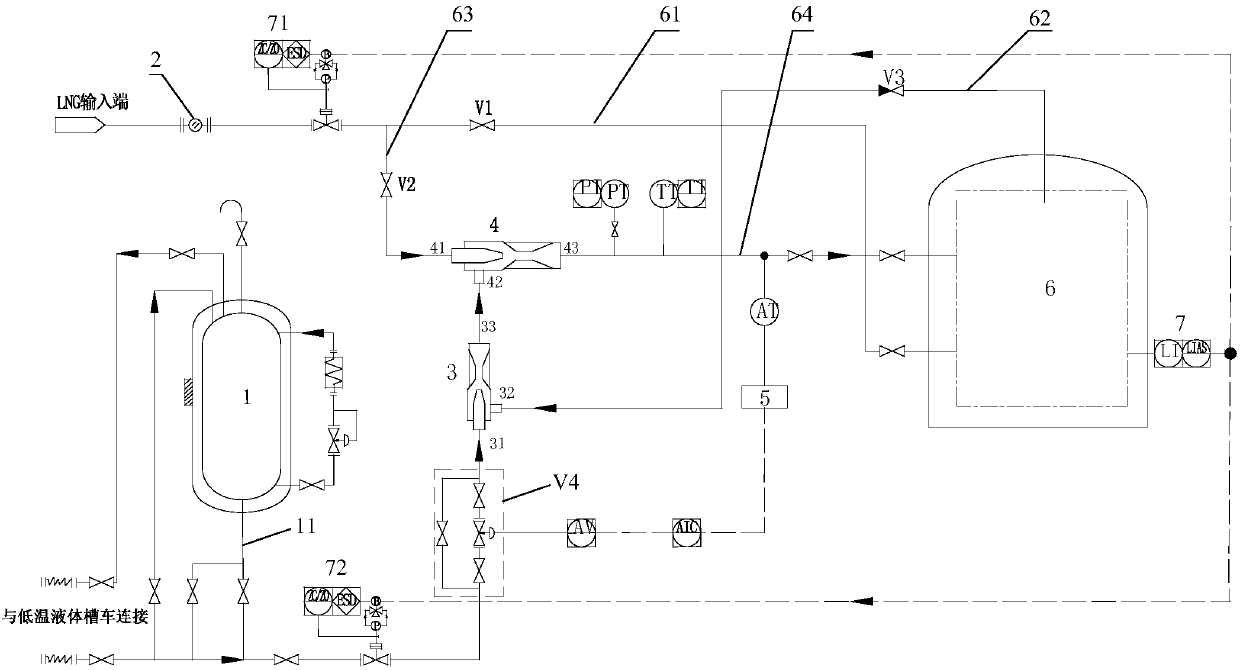

[0023] In view of the shortcomings of the above-mentioned prior art, the object of the present invention is to provide a BOG liquefaction and recovery system for liquefied natural gas, which can realize the recovery of BOG from LNG receiving terminals such as LNG receiving stations, natural gas liquefaction stations and LNG filling stations. The cold energy provided by the cryogenic liquid is used to carry out primary liquefaction of BOG. After the primary liquefaction, the mixed liquid absorbs the cold energy of LNG and then liquefies into LNG which is all in a liquid state and has no gas phase. The invention only utilizes the pressure of the gaseous BOG in the LNG storage tank and the low-pressure suction function of the main jet mixer and the secondary jet mixer as the power for the fluid to flow in the pipeline, optimizes the BOG reliquefaction process, and does not need to be equipped with cryogenic compressors and pumps Equipment such as recondensers and recondensers sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com