Resourceful treatment method and system of lithium battery cathode material production wastewater

A cathode material, a technology for producing wastewater, which is applied in the fields of natural water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The process system is simple and the effect of recycling is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

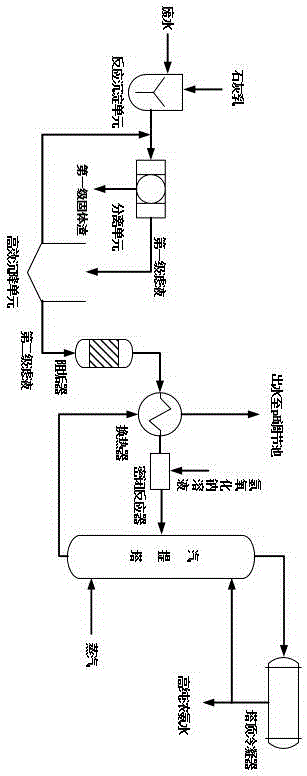

Image

Examples

Embodiment 1

[0033] A kind of waste water from the production of positive electrode materials of lithium batteries enters the reaction precipitation unit after pretreatment, reacts with lime milk, adds lime milk while stirring, and controls the pH of the reaction liquid to be 10, and then pumps the mixed slurry into the separation unit, and the solid slag is discharged Transport, the first-stage filtrate enters the high-efficiency settling unit for further precipitation and separation, the solid slag is transported outside, and the second-stage filtrate enters the heat exchanger after passing through the scale inhibitor and exchanges heat with the water at the bottom of the stripping tower of the deamination unit. After increasing the temperature Enter the closed reactor, react with sodium hydroxide solution, stir and mix thoroughly, then enter the stripping tower for stripping and distilling ammonia, the ammonia gas enters the condenser from the top of the tower, part of it is refluxed, and...

Embodiment 2

[0035] A kind of waste water from the production of cathode materials for lithium batteries enters the reaction precipitation unit after pretreatment, reacts with milk of lime, adds milk of lime while stirring, and controls the pH of the reaction solution to 6.5, then pumps the mixed slurry into the separation unit, and the solid slag is discharged Transport, the first-stage filtrate enters the high-efficiency settling unit for further precipitation and separation, the solid slag is transported outside, and the second-stage filtrate enters the heat exchanger after passing through the scale inhibitor and exchanges heat with the water at the bottom of the stripping tower of the deamination unit. After increasing the temperature Enter the closed reactor, react with sodium hydroxide solution, stir and mix thoroughly, then enter the stripping tower for stripping and distilling ammonia, the ammonia gas enters the condenser from the top of the tower, part of it is refluxed, and part of...

Embodiment 3

[0037] A kind of waste water from the production of positive electrode materials of lithium batteries enters the reaction precipitation unit after pretreatment, reacts with lime milk, adds lime milk while stirring, and controls the pH of the reaction solution to be 8, and then pumps the mixed slurry into the separation unit, and the solid slag is discharged Transport, the first-stage filtrate enters the high-efficiency settling unit for further precipitation and separation, the solid slag is transported outside, and the second-stage filtrate enters the heat exchanger after passing through the scale inhibitor and exchanges heat with the water at the bottom of the stripping tower of the deamination unit. After increasing the temperature Enter the closed reactor, react with sodium hydroxide solution, stir and mix thoroughly, then enter the stripping tower for stripping and distilling ammonia, the ammonia gas enters the condenser from the top of the tower, part of it is refluxed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com