Incineration treatment method for domestic refuse

A technology of domestic waste and treatment method, applied in combustion methods, incinerators, cement production and other directions, can solve the problems of difficult equipment maintenance, large volume of rotary kiln equipment, and high civil construction costs, and achieve the effect of full and uniform combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

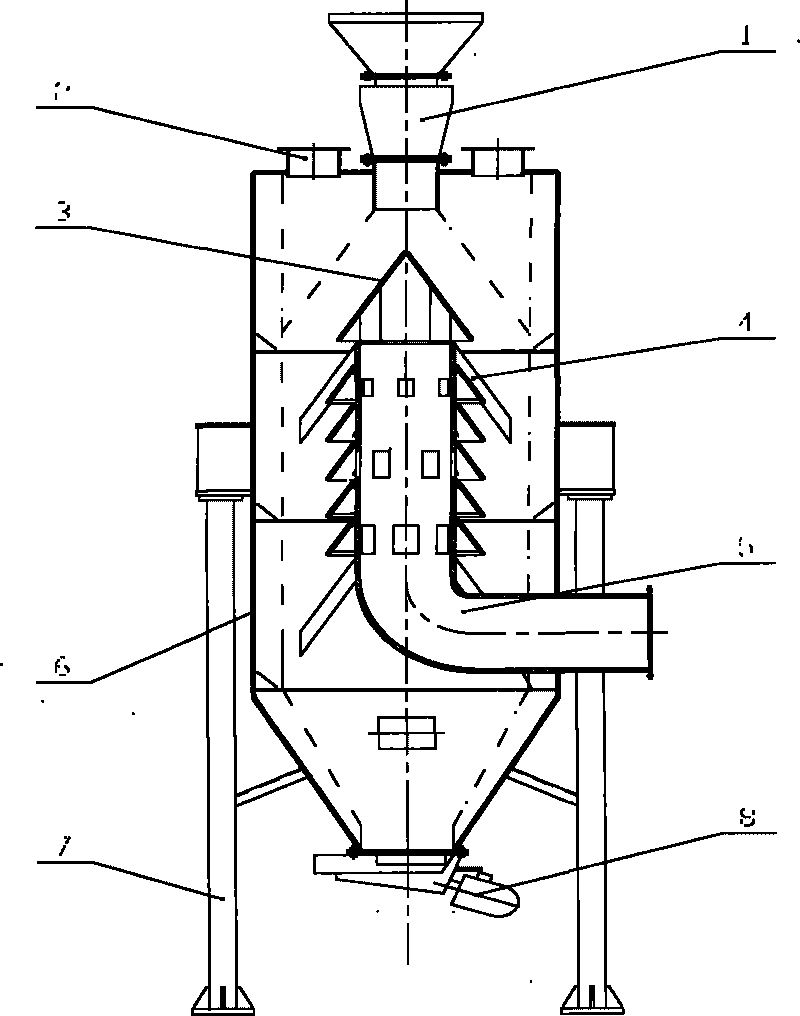

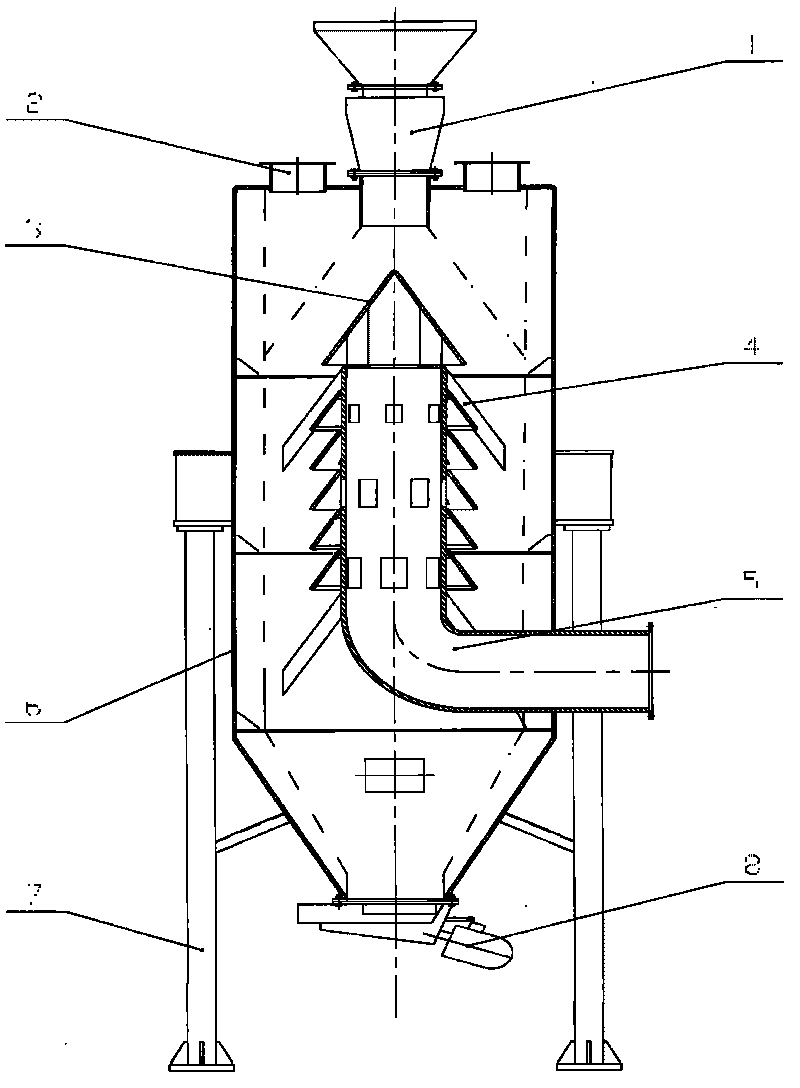

[0033] to combine figure 1, the present invention is used to realize the incinerator in the incineration treatment method of the domestic waste by electric control feeder 1, smoke outlet 2, distribution body 3, support plate 4, wind tower 5, furnace body 6, support column 7 Composed of electric vibrating discharger 8, the upper section of the furnace body 6 is in the shape of a vertical cylinder, and the lower section is in the shape of an inverted round platform. The furnace body with this structure can obtain the largest working volume in the most limited space. An electric control feeder 1 is arranged in the middle of the top of the upper section of the furnace body 6. The feeding port of the electric control feeder 1 is in the shape of a round table with a large upper part and a smaller bottom. The feeding port of the electric control feeder 1 is cylindrical and extends into Inside the furnace, it is very conducive to the feeding and unloading of garbage. The top of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com