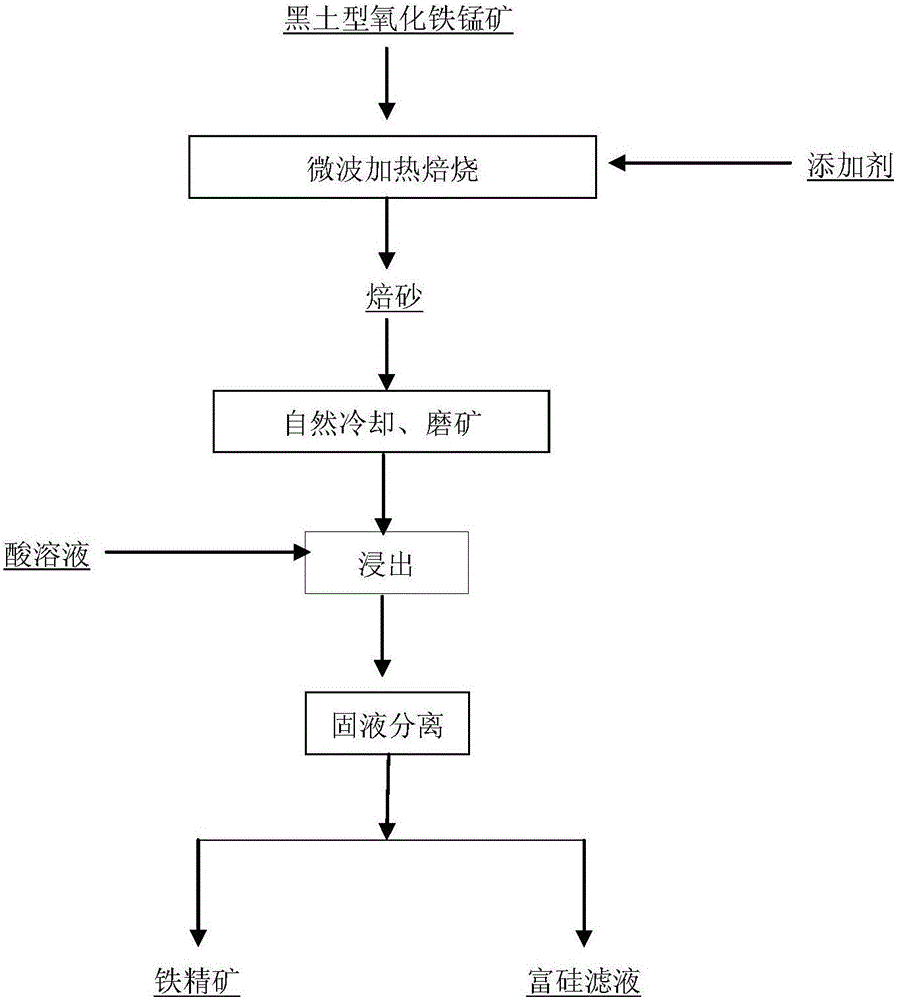

Chemical desiliconization method and application in black soil type iron oxide manganese ore beneficiation

A technology for oxidizing iron-manganese ore and desiliconization, which is applied in the field of mineral engineering, can solve the problems of complex process flow, high equipment requirements, and high roasting costs, and achieve the effect of broad application prospects, low equipment requirements, and high desiliconization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

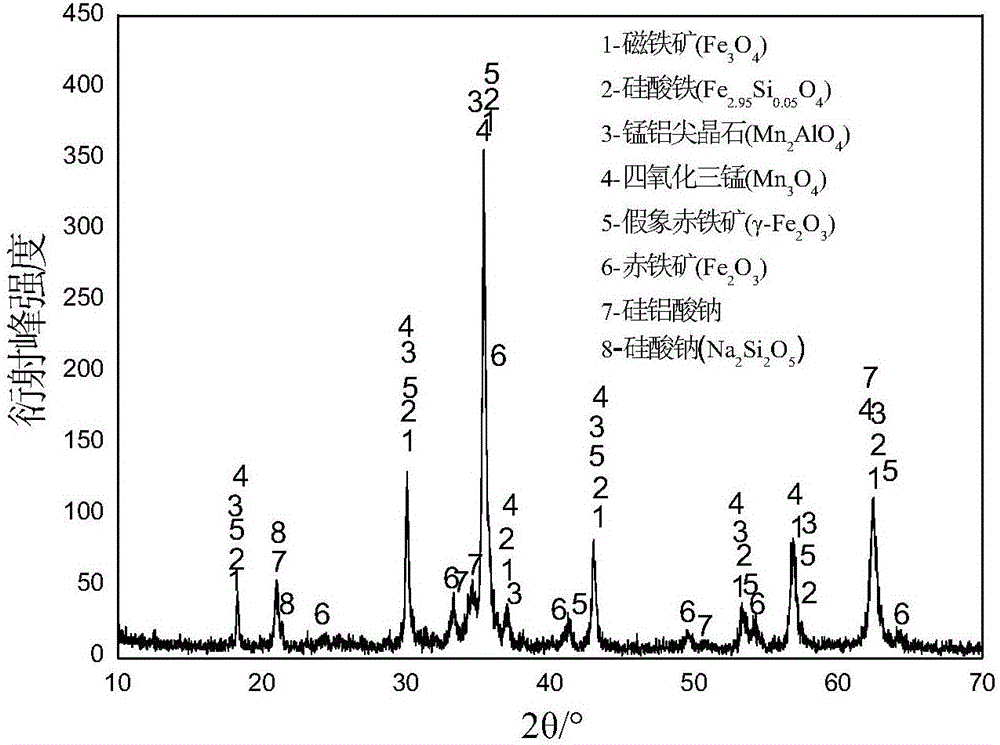

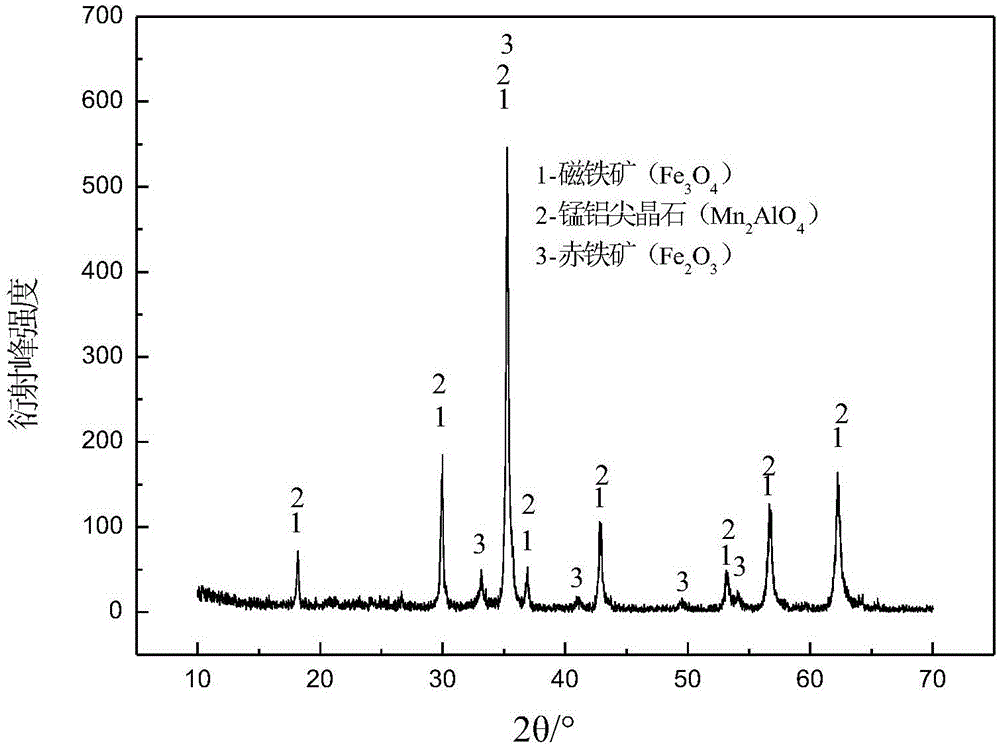

[0036] The ore sample is black soil iron manganese oxide ore in Lanshan County, Yongzhou, Hunan. The ore is crushed to a particle size of less than 0.25mm. The main chemical composition and element content of the ore are shown in Table 1. The elements with higher content in the ore sample are iron, manganese, aluminum and silicon. The main phase compositions of iron and manganese are limonite and ferromanganese spinel, accounting for about 99% and 86.80% respectively, and the grades of iron and manganese are 40.10% and 8.69% respectively. Gangue minerals mainly exist in the form of aluminosilicate, with a silicon dioxide content of 8.92% and an aluminum oxide content of 13.06%. Useful minerals and gangue minerals are distributed in fine grains, which belong to extremely difficult limonite. Alkali lignin, purchased from Shandong Weili Chemical Technology Co., Ltd., is a by-product of papermaking, an industrial product, with a molecular weight of 1,000-100,000, and its main te...

Embodiment 2

[0042] The ore sample and alkali lignin used are the same as in Example 1. Mix 5% alkali lignin, 13% sodium carbonate and the ore sample evenly, then reduce and roast, the roasting temperature is 300°C, and the roasting time is 60 minutes, the iron grade is 58.40%, the iron recovery rate is 91.26%, and the yield rate is 62.45%. Iron ore concentrate, in which the manganese content is 9.48%, its Al and Si content are reduced from 9.40% and 6.92% of the original ore to 2.57% and 0.69%, and the leaching rates of Al and Si reach 82.93% and 93.77% respectively. The leaching sulfuric acid concentration is 2mol / L, the leaching time is 5min, the leaching temperature is 60°C, and the liquid-solid ratio is 10:1.

Embodiment 3

[0044] The ore sample and alkali lignin used are the same as in Example 1. Control the amount of alkali lignin to 5%, the amount of calcium carbonate to 7%, the roasting temperature is 100°C, and the roasting time is 30 minutes. L. The liquid-solid ratio is 10:1, and the leaching time is 5 minutes. The iron grade is 51.02%, the recovery rate is 99.21%, and the yield rate is 83.74%. The content of Al and Si decreased from 9.40% and 6.92% of the original ore to 4.71% and 2.17%, and the leaching rate of Al and Si reached 58.04% and 73.74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com